Rare earth composite metaphosphate coated lithium positive material and preparation method thereof

A metaphosphate and rare earth composite technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of unstable surface structure and failure of lithium positive electrode material, achieve good cycle performance and thermal stability, production equipment Low requirements and the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

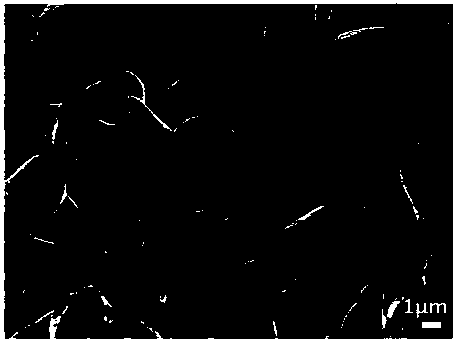

Image

Examples

Embodiment 1

[0044] Weighing common three-element materials (Ni:Co:Mn=5:2:3) and 0.10LiPO 3 ·0.10(Na 0.1 Al 0.4 Nb 0.5 )(PO 3 ) 3.8 ·0.80Sc (PO 3 ) 3 , the quality of rare earth composite metaphosphate is 2.0% of common three-element materials, pour it into the material tank, add grinding balls, and the amount of grinding balls added is 1 times the total mass of the material. Mix on a 3D mixer for 1 hour. The mixed material was calcined in a muffle furnace at 700°C for 1 hour. The calcined block is ground and passed through a 300-mesh sieve to obtain a rare earth composite metaphosphate-coated tri-element material.

Embodiment 2

[0046] Weighing common three-element materials (Ni:Co:Mn=5:2:3) and 0.10LiPO 3 ·0.10(Na 0.1 Al 0.5 Nb 0.5 )(PO 3 ) 3.8 ·0.80Y (PO 3 ) 3 , the quality of rare earth composite metaphosphate is 2.0% of common three-element materials, pour it into the material tank, add grinding balls, and the amount of grinding balls added is 1 times the total mass of the material. Mix on a 3D mixer for 1 hour. The mixed material was calcined in a muffle furnace at 700°C for 1 hour. The calcined block is ground and passed through a 300-mesh sieve to obtain a rare earth composite metaphosphate-coated tri-element material.

Embodiment 3

[0048] Weighing common three-element materials (Ni:Co:Mn=5:2:3) and 0.10LiPO 3 ·0.10(Na 0.1 Al 0.5 Nb 0.5 )(PO 3 ) 3.8 ·0.80La(PO 3 ) 3 , the quality of rare earth composite metaphosphate is 1.0% of common three-element materials, pour it into the material tank, add grinding balls, and the amount of grinding balls added is 1 times the total mass of the material. Mix on a 3D mixer for 1 hour. The mixed material was calcined in a muffle furnace at 700°C for 1 hour. The calcined block is ground and passed through a 300-mesh sieve to obtain a rare earth composite metaphosphate-coated tri-element material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com