Soft magnetic alloy powder, wave absorbing sheet, preparation method thereof, electronic components and electronic equipment

A technology of electronic components and soft magnetic alloys, applied in electrical components, metal processing equipment, magnetic field/electric field shielding, etc., can solve the problems of low magnetic permeability of wave-absorbing plates, improve electromagnetic performance, improve conversion efficiency, and improve The effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

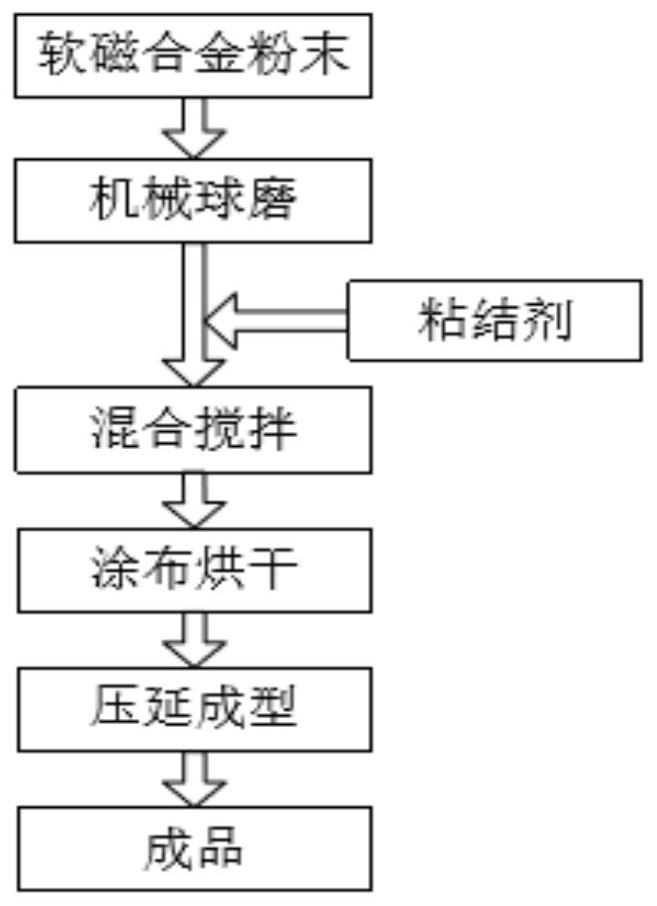

[0048] According to a first aspect of the present invention, a method for preparing a soft magnetic alloy powder is provided, comprising the following steps:

[0049] (a) Perform mechanical ball milling on the soft magnetic alloy powder to obtain flattened soft magnetic alloy powder; during the mechanical ball milling process, the ball: material: dispersant: solvent mass ratio is (8-12): (0.5-1.5): (0.02-0.08): (0.05-0.15);

[0050] (b) annealing the flattened soft magnetic alloy powder in a protective atmosphere at 700-900°C;

[0051] (c) Sieving the annealed flattened soft magnetic alloy powder to obtain flattened soft magnetic alloy powder with an aspect ratio of 100-200.

[0052] The type and size of the soft magnetic alloy powder are not limited, and the conventional selection of wave absorbing agents in the field can be referred to. Typical but non-limiting examples of the soft magnetic alloy powder are sendust soft magnetic alloy powder, iron-nickel soft magnetic allo...

Embodiment 1

[0109] A kind of preparation method of wave-absorbing film comprises the following steps:

[0110] (1) Take an appropriate amount of Fe-Si-Al soft magnetic alloy powder and add it to a planetary ball mill, mix the materials according to the mass ratio of ball: material: dispersant: solvent = 10:1:0.05:0.1, and the ball mill speed is 300r / min, The soft magnetic alloy powder is mechanically milled by means of forward and reverse alternating ball milling, alternately every 30 minutes, and the ball milling time is 240 minutes, to obtain a flattened sendust soft magnetic alloy powder with a diameter-thickness ratio of 80-150;

[0111] (2) The flat iron-silicon-alumina soft magnetic alloy powder is annealed in a nitrogen protective atmosphere when the temperature rises from room temperature to 800 ° C, and the annealing time is 6 hours;

[0112] (3) Add modified polyurethane binder to the flattened sendust soft magnetic alloy powder after annealing, and add dimethylformamide in the ...

Embodiment 2

[0119] Step (1) Other conditions remain unchanged during ball milling of the sendust soft magnetic alloy powder, and the ball milling time is changed to 360 minutes to obtain flat sendust powder with an diameter-thickness ratio of 100-200. The rest of the preparation steps are the same as in Example 1.

[0120] The wave-absorbing sheet thus prepared was tested with an Agilent E4991B impedance analyzer, and its magnetic permeability data are shown in Table 2.

[0121] Table 2

[0122] frequency 3MHz 13.56MHz μ’ 225.53 166.29 μ” 19.84 61.81

PUM

| Property | Measurement | Unit |

|---|---|---|

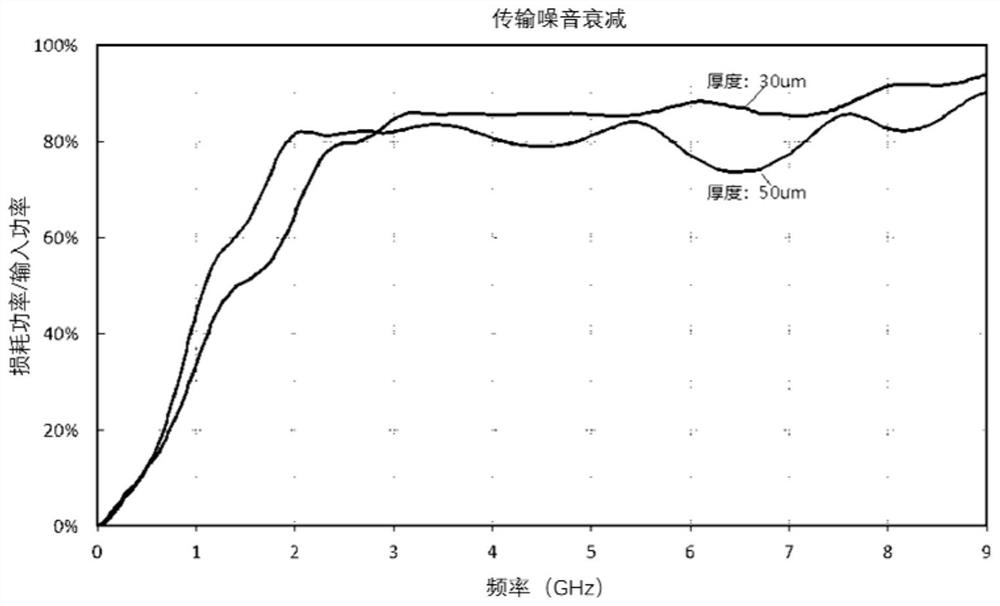

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

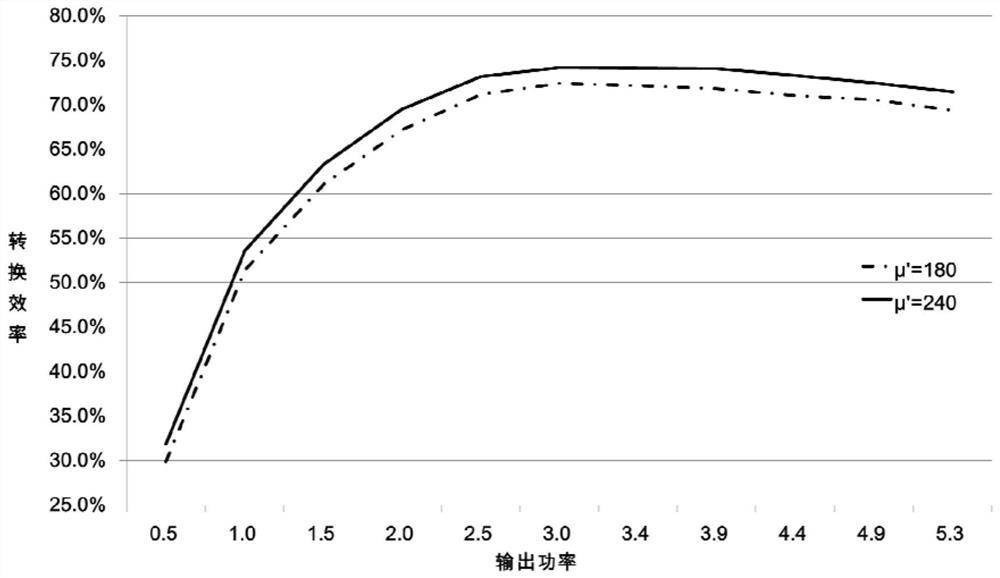

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com