Guide rail positioning method and device thereof based on bar code technology

A positioning method and a technology of a positioning device, which are applied in two-dimensional position/course control, vehicle position/route/height control, non-electric variable control, etc., can solve problems such as poor repeat positioning accuracy, and achieve smooth acceleration and deceleration, Improve the repeat positioning accuracy and the effect of accurate marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

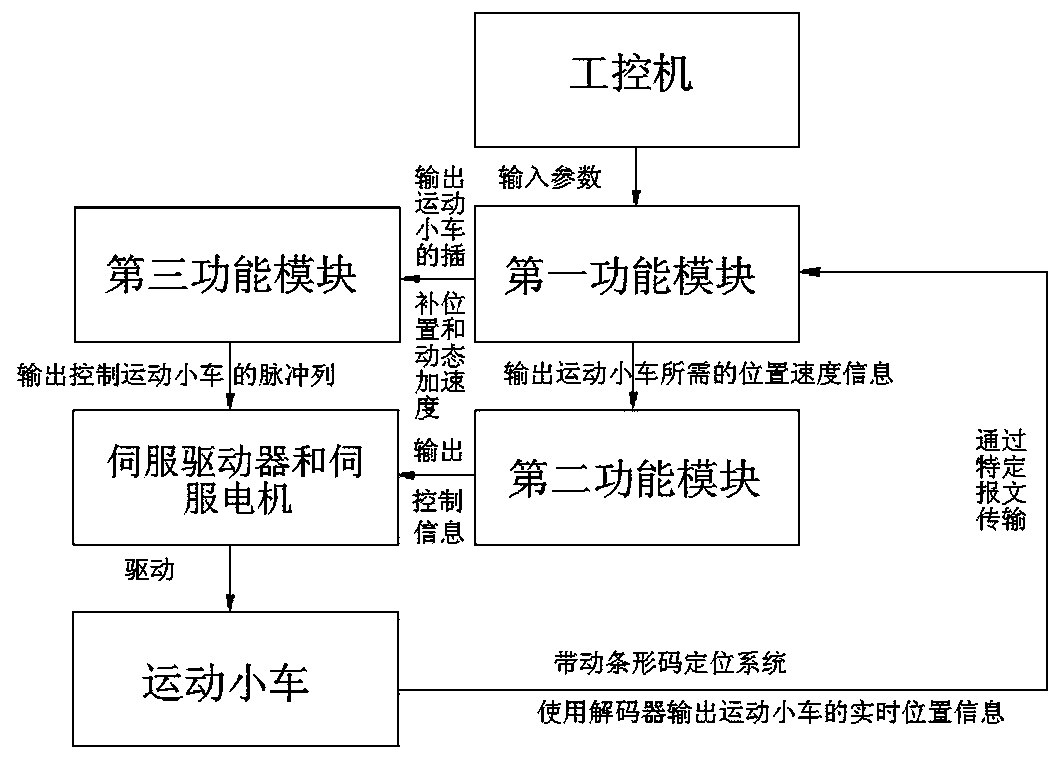

[0021] Such as figure 1 As shown, the embodiment of the present invention provides a guide rail positioning method based on barcode technology, including the following steps: input the parameters of the delay, speed, angle, number of turns and direction of rotation of the moving car to the industrial computer, and the industrial computer converts the above parameters Transfer to the first function module in the programmable logic controller.

[0022] The first function module calculates the actual required speed of the moving car and the engineering unit of the actual position of the barcode according to the received device parameter information, and sends it to the second function module, which receives and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com