Method for preparing micro-nano structure on the surface of tungsten material and tungsten material with micro-nano structure on the surface and application thereof

A micro-nano structure and nano-technology, applied in the field of material surface micro-nano structure preparation, can solve the problems of large reaction area, low precision, and low preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

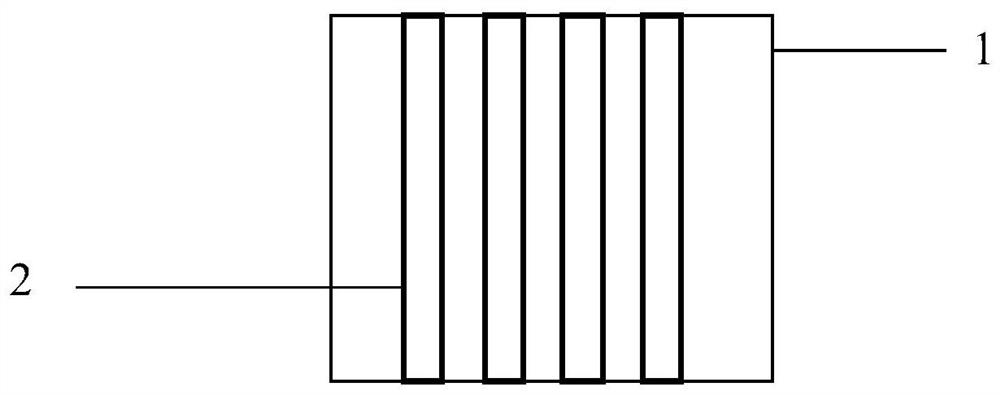

[0023] The invention provides a method for preparing a micro-nano structure on the surface of a tungsten material, comprising the following steps:

[0024] Under vacuum conditions, use a helium ion microscope to perform the first ion etching on the surface of the tungsten material to obtain etched micro-regions;

[0025] Under vacuum conditions, the second ion etching is performed on the etched micro-region by using a helium ion microscope, forming nano-stripes in the etched micro-region, and obtaining a micro-nano structure on the surface of the tungsten material.

[0026] In the invention, the first ion etching is carried out on the surface of the tungsten sheet by using a helium ion microscope under vacuum conditions to obtain etched micro-regions.

[0027] In the present invention, the tungsten material preferably includes sequential machining, polishing and ultrasonic cleaning before use. In the present invention, there is no special limitation on the mechanical processi...

Embodiment 1

[0039] The tungsten block is prepared by mechanical processing into a tungsten sheet with a diameter of 3 mm and a thickness of 1 mm, and then mechanically polished to a surface roughness of 2 μm, and then ultrasonically cleaned with industrial ethanol at 300 W for 5 minutes to obtain a tungsten material;

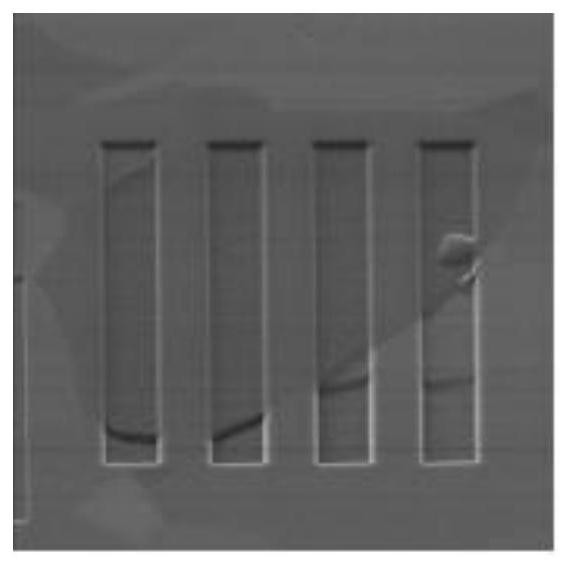

[0040] The tungsten material is placed in a helium ion microscope, and the vacuum degree is pumped to 10 -3 When Pa is lower than Pa, the gallium ion source is used to perform the first ion etching on any surface of the tungsten sheet to obtain a square etched micro-region with a side length of 5 μm and an etching depth of 5 μm. The working conditions of the helium ion microscope are: accelerated The voltage is 25kV, the beam current is 10pA, and the incident angle is 45°;

[0041] The resulting tungsten material with etched micro-regions was placed in a helium ion microscope at a vacuum of 10 -3 Under the condition below Pa, the gallium ion source is used to carry out the...

Embodiment 2

[0043] The tungsten block is prepared by mechanical processing into a tungsten sheet with a diameter of 10mm and a thickness of 2mm. After mechanical polishing, the surface roughness is 5μm, and then ultrasonic cleaning is performed with industrial ethanol at 700W for 10min to obtain a tungsten material;

[0044] The tungsten material is placed in a helium ion microscope, and the vacuum degree is pumped to 10 -3 When Pa is lower than Pa, the gallium ion source is used to perform the first ion etching on any surface of the tungsten sheet to obtain a square etched micro-region with a side length of 10 μm and an etching depth of 5 μm. The working conditions of the helium ion microscope are: accelerated The voltage is 30kV, the beam current is 15pA, and the incident angle is 45°;

[0045] The resulting tungsten material with etched micro-regions was placed in a helium ion microscope at a vacuum of 10 -3 Under the condition below Pa, the gallium ion source is used to carry out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com