Method for decomposing high-grade mixture rare earth concentrate through low-temperature roasting pretreatment of concentrated sulfuric acid

A technology of low-temperature pretreatment and mixed rare earth, which is applied in the field of rare earth concentrate decomposition, low-temperature pretreatment concentrated sulfuric acid roasting and decomposition of high-grade mixed rare earth concentrate, which can solve the problems of low energy consumption and waste residue reduction, and achieve the purpose of increasing the contact area, The effect of reducing the amount of waste residue and increasing process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

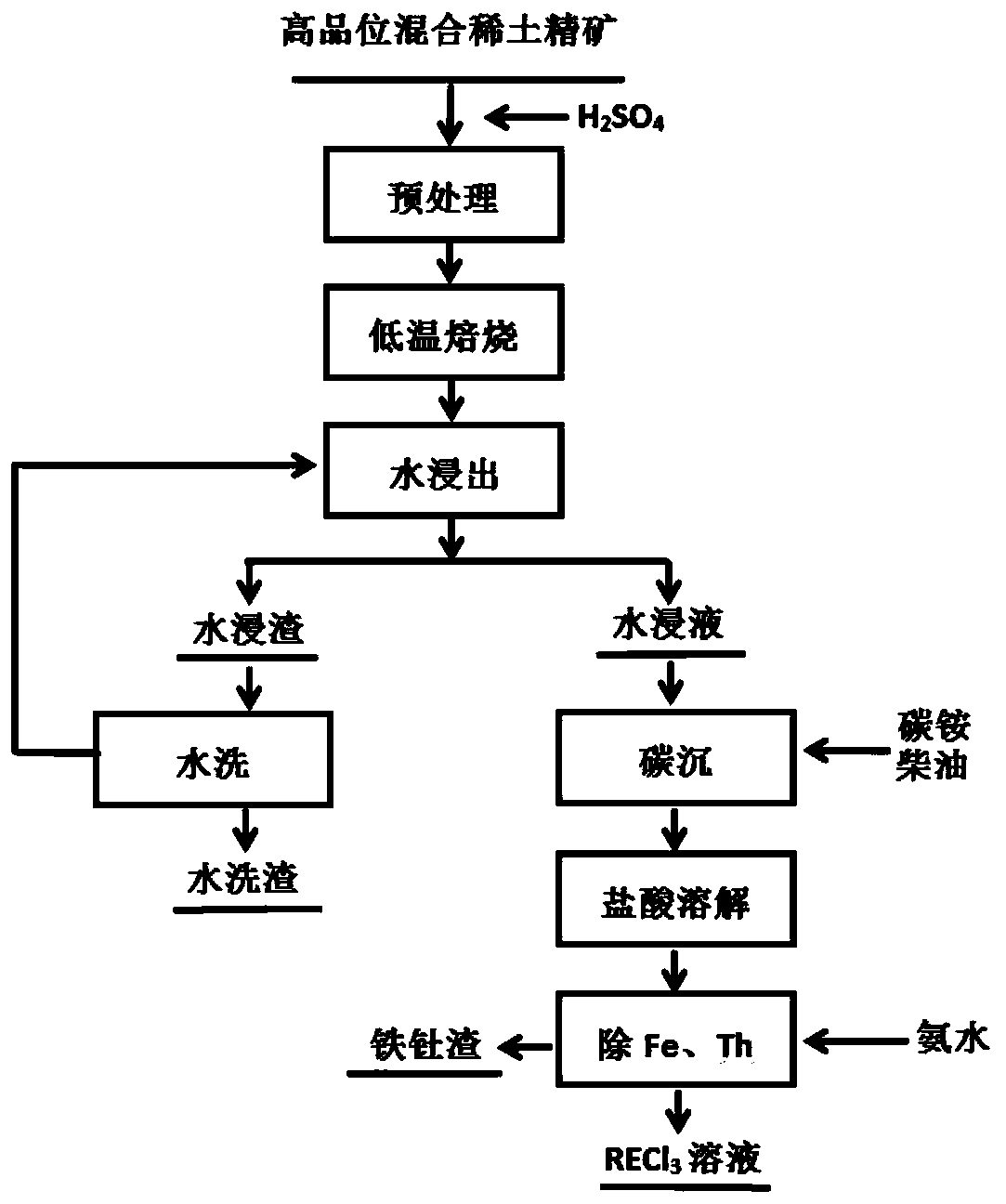

[0035] combine figure 1 A method for roasting and decomposing high-grade mixed rare earth concentrate with low-temperature pretreatment concentrated sulfuric acid, specifically comprising the following steps:

[0036] S1: Take 10g of high-grade mixed rare earth concentrate and 20g of concentrated sulfuric acid, mix them evenly, and place them in a steel reactor for 5 minutes at room temperature. in,

[0037] The mixed rare earth concentrate in step (1) is one of bastnaesite and monazite or a mixed rare earth concentrate composed of the two. Rare earth grade REO≥58%, the best rare earth grade REO≥65%.

[0038] S2: Roast the obtained material at 300° C. for 2 hours to obtain concentrated sulfuric acid roasted ore.

[0039] S3: Combine the above concentrated sulfuric acid roasted ore with H 2After O is uniformly mixed, the solid-to-liquid ratio is 1:4, the stirring speed is 500r / min, the reaction temperature is 25°C, and the reaction time is 4h, filter to obtain water immersi...

Embodiment 2

[0052] On the basis of Example 1, combined with figure 1 A method for roasting and decomposing high-grade mixed rare earth concentrate with low-temperature pretreatment concentrated sulfuric acid, specifically comprising the following steps:

[0053] S1: Take 10g of high-grade mixed rare earth concentrate and 12g of concentrated sulfuric acid, mix them evenly, and then place them in a steel reactor for 30 minutes at room temperature. in,

[0054] The mixed rare earth concentrate in step (1) is one of bastnaesite and monazite or a mixed rare earth concentrate composed of the two. Rare earth grade REO≥58%, the best rare earth grade REO≥65%.

[0055] S2: Roasting the obtained material at 180° C. for 5 hours to obtain concentrated sulfuric acid roasted ore.

[0056] S3: Combine the above concentrated sulfuric acid roasted ore with H 2 After O is evenly mixed, the solid-to-liquid ratio is 1:2, the stirring speed is 600r / min, the reaction temperature is 30°C, and the reaction ti...

Embodiment 3

[0067] On the basis of the above examples, combined with figure 1 A method for roasting and decomposing high-grade mixed rare earth concentrate with low-temperature pretreatment concentrated sulfuric acid, specifically comprising the following steps:

[0068] S1: Take 10g of high-grade mixed rare earth concentrate and 25g of concentrated sulfuric acid and mix them evenly, then place them in a steel reactor for 3 minutes at room temperature. in,

[0069] The mixed rare earth concentrate in step (1) is one of bastnaesite and monazite or a mixed rare earth concentrate composed of the two. The rare earth grade REO≥58%, the best rare earth grade REO≥65%.

[0070] S2: Roasting the obtained material at 550° C. for 0.5 h to obtain concentrated sulfuric acid roasted ore.

[0071] S3: Combine the above concentrated sulfuric acid roasted ore with H 2 After O is uniformly mixed, the solid-liquid ratio is 1:6, the stirring speed is 100r / min, the reaction temperature is 10°C, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com