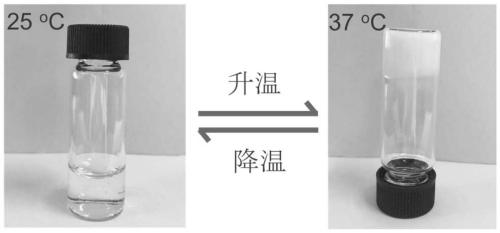

Non-trypsinization harvested cell culture method based on temperature sensitive hydrogel material

A temperature-sensitive hydrogel and cell culture technology, which is applied in the field of non-trypsinized harvested cell culture based on temperature-sensitive hydrogel materials, can solve the problems of cell function loss, cell membrane damage, weakening the application value of seed cells, etc., and achieve high viability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

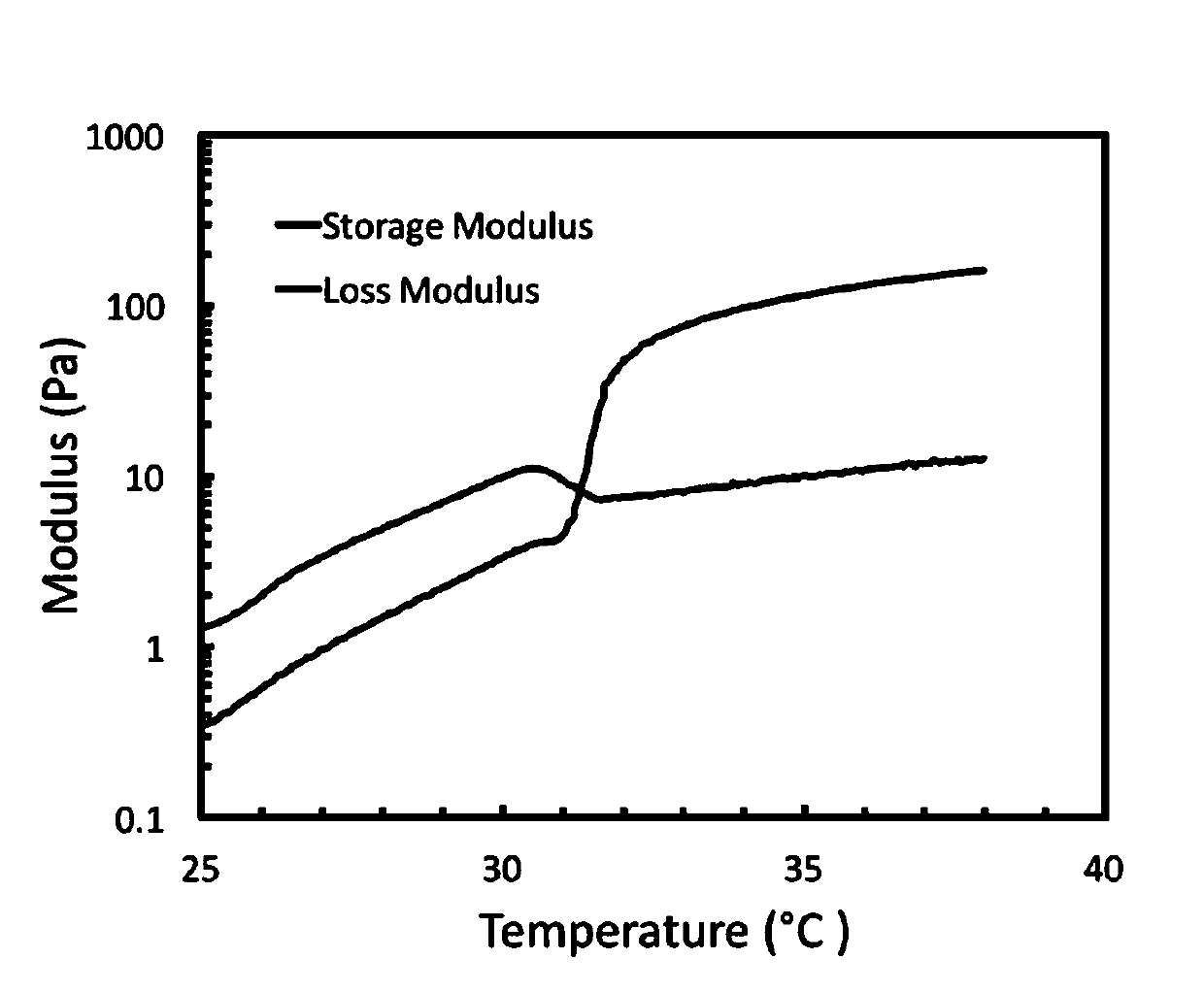

Method used

Image

Examples

Embodiment 1

[0021] 1) Take 1.5g of chitosan powder, 1.75g of N-isopropylacrylamide, 0.075g of ammonium persulfate with a viscosity-average molecular weight of 65w and a degree of deacetylation of 90%, and disperse them in 95 milliliters of deionized water, then, Add 0.2mL of hydrochloric acid, stir and dissolve evenly, react at 60°C for 8 hours, then use deionized water to dialyze the reaction product to neutrality, and vacuum freeze-dry to obtain poly-N-isopropylacrylamide modified chitosan powder ;

[0022] 2) Weigh 1.0 g of the poly-N-isopropylacrylamide modified chitosan powder obtained in step 1), disperse it in 25 milliliters of PBS solution, stir and dissolve to obtain poly-N-isopropylacrylamide modified chitosan powder with a mass concentration of 4%. Propylacrylamide modified chitosan aqueous solution;

[0023] 3) Mix 0.75mL of the poly-N-isopropylacrylamide-modified chitosan solution prepared in step 2) and 0.25mL of the cell suspension at room temperature, then add it to the...

Embodiment 2

[0027] 1) Take 1.5g of chitosan powder, 1.75g of N-isopropylacrylamide, 0.075g of ammonium persulfate with a viscosity-average molecular weight of 65w and a degree of deacetylation of 90%, and disperse them in 95 milliliters of deionized water, then, Add 0.2mL of hydrochloric acid, stir and dissolve evenly, react at 60°C for 8 hours, then use deionized water to dialyze the reaction product to neutrality, and vacuum freeze-dry to obtain poly-N-isopropylacrylamide modified chitosan powder ;

[0028] 2) Weigh 1.0 g of the poly-N-isopropylacrylamide modified chitosan powder obtained in step 1), disperse it in 25 milliliters of PBS solution, stir and dissolve to obtain poly-N-isopropylacrylamide modified chitosan powder with a mass concentration of 4%. Propylacrylamide modified chitosan aqueous solution;

[0029] 3) Apply 0.75 mL of the poly-N-isopropylacrylamide-modified chitosan solution prepared in step 2) to the bottom of the culture dish at room temperature, and then place ...

Embodiment 3

[0031] 1) Take 1.5g of chitosan powder, 1.75g of N-isopropylacrylamide, 0.075g of ammonium persulfate with a viscosity-average molecular weight of 65w and a degree of deacetylation of 90%, and disperse them in 95 milliliters of deionized water, then, Add 0.2mL of hydrochloric acid, stir and dissolve evenly, react at 60°C for 8 hours, then use deionized water to dialyze the reaction product to neutrality, and vacuum freeze-dry to obtain poly-N-isopropylacrylamide modified chitosan powder ;

[0032] 2) Weigh 1.5g of the poly-N-isopropylacrylamide modified chitosan powder obtained in step 1), disperse it in 30 milliliters of PBS solution, stir and dissolve to obtain poly-N-isopropylacrylamide modified chitosan powder with a mass concentration of 5%. Propylacrylamide modified chitosan aqueous solution;

[0033] 3) Mix 0.75mL of the poly-N-isopropylacrylamide-modified chitosan solution prepared in step 2) and 0.25mL of the cell suspension evenly at a lower temperature, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com