A kind of elastic short fiber toughened crystalline polymer product and preparation method thereof

A technology of crystalline polymers and short fibers, applied in the direction of conjugated synthetic polymer artificial filaments, additive processing, etc., can solve the problems of polylactic acid impact strength and tensile strength decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Take the elastomeric polyurethane resin and put it into a vacuum oven at 80° C. to dry for 4 hours to obtain the dried elastomeric polyurethane resin for future use.

[0037] (2) Take the crystalline polylactic acid resin and put it into a vacuum oven at 80° C. to dry for 8 hours to obtain a dried crystalline polylactic acid resin for future use.

[0038] (3) raw materials are weighed according to the following mass percentages: 10% of the dried elastomer polyurethane resin obtained in step (1), 90% of the dried crystalline polylactic acid resin obtained in step (2), the mass percentages of the two raw materials The sum is 100%.

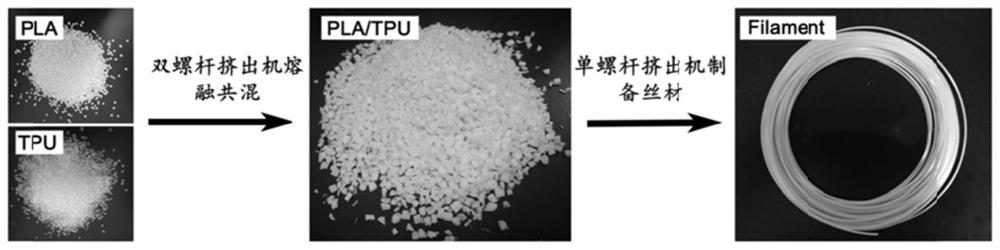

[0039] (4) Mix the raw materials weighed in step (3) and perform melt blending and granulation with twin-screws to obtain composite pellets with a diameter of 1.3 to 2.5 mm and a length of 5 to 7 mm, and vacuum-dry at 80°C for 12 hours Standby, during the extrusion process, the twin-screw speed is controlled at 160-180r / min, and the blend...

Embodiment 2

[0043] (1) Take the elastomeric polyurethane resin and put it into a vacuum oven at 80° C. to dry for 4 hours to obtain the dried elastomeric polyurethane resin for future use.

[0044] (2) Take the crystalline polylactic acid resin and put it into a vacuum oven at 80° C. to dry for 8 hours to obtain a dried crystalline polylactic acid resin for future use.

[0045] (3) raw materials are weighed according to the following mass percentages: 20% of the dried elastomer polyurethane resin obtained in step (1), 80% of the dried crystalline polylactic acid resin obtained in step (2), the mass percentages of the two raw materials The sum is 100%.

[0046] (4) Mix the raw materials weighed in step (3) and perform melt blending and granulation with twin-screws to obtain composite pellets with a diameter of 1.3 to 2.5 mm and a length of 5 to 7 mm, and vacuum-dry at 80°C for 12 hours Standby, during the extrusion process, the twin-screw speed is controlled at 160-180r / min, and the blend...

Embodiment 3

[0050] (1) Take the elastomeric polyurethane resin and put it into a vacuum oven at 80° C. to dry for 4 hours to obtain the dried elastomeric polyurethane resin for future use.

[0051] (2) Take the crystalline polylactic acid resin and put it into a vacuum oven at 80° C. to dry for 8 hours to obtain a dried crystalline polylactic acid resin for future use.

[0052] (3) raw materials are weighed according to the following mass percentages: 30% of the dried elastomer polyurethane resin obtained in step (1), 70% of the dried crystalline polylactic acid resin obtained in step (2), the mass percentages of the two raw materials The sum is 100%.

[0053] (4) Mix the raw materials weighed in step (3) and perform melt blending and granulation with twin-screws to obtain composite pellets with a diameter of 1.3 to 2.5 mm and a length of 5 to 7 mm, and vacuum-dry at 80°C for 12 hours Standby, during the extrusion process, the twin-screw speed is controlled at 160-180r / min, and the blend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com