A preparation method of high-magnification conductive polypropylene foam beads

A technology of foamed beads and polypropylene, which is applied in the field of polypropylene foamed beads, can solve problems such as poor electrical conductivity and high resistivity, and achieve the effects of avoiding agglomeration, enhancing electrical conductivity, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

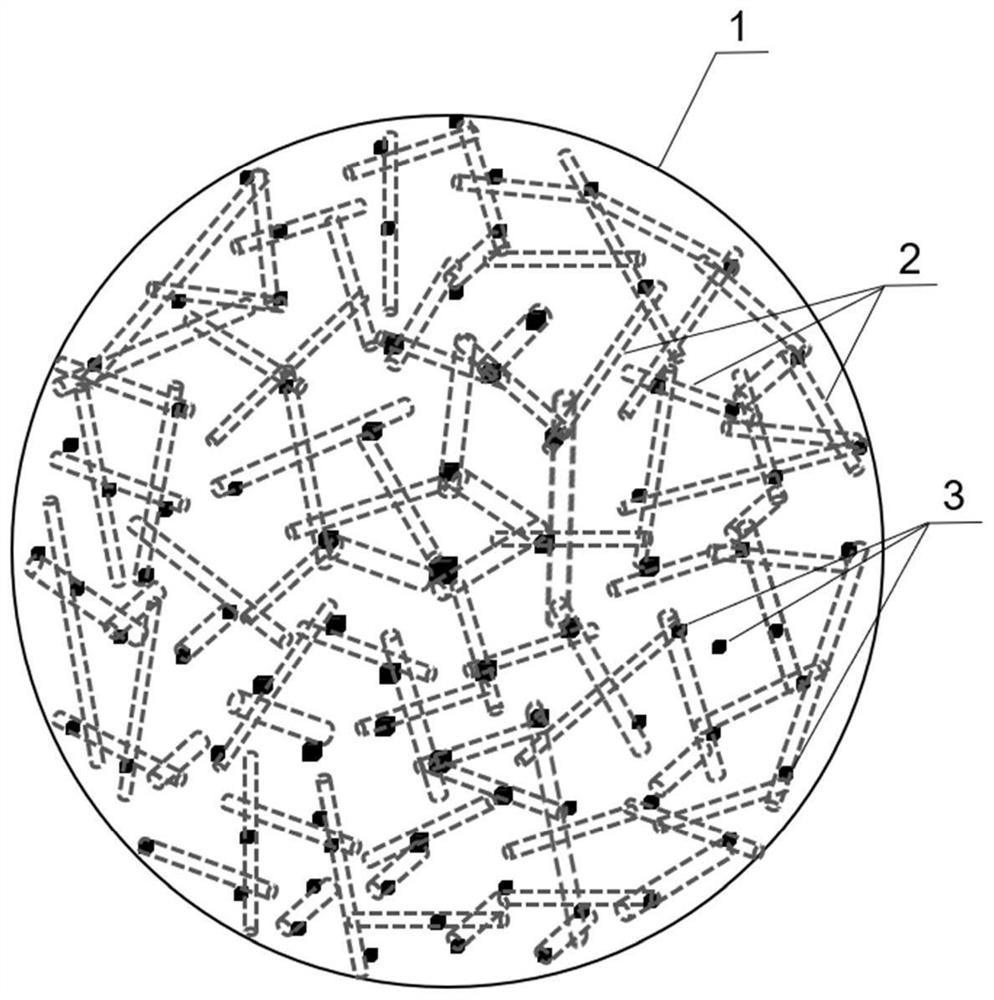

[0040] The preparation method of high-magnification conductive polypropylene foam beads comprises the following steps:

[0041] A. After mixing the polypropylene resin and conductive carbon black uniformly in a certain proportion, the conductive masterbatch 1 is obtained through twin-screw extrusion processing;

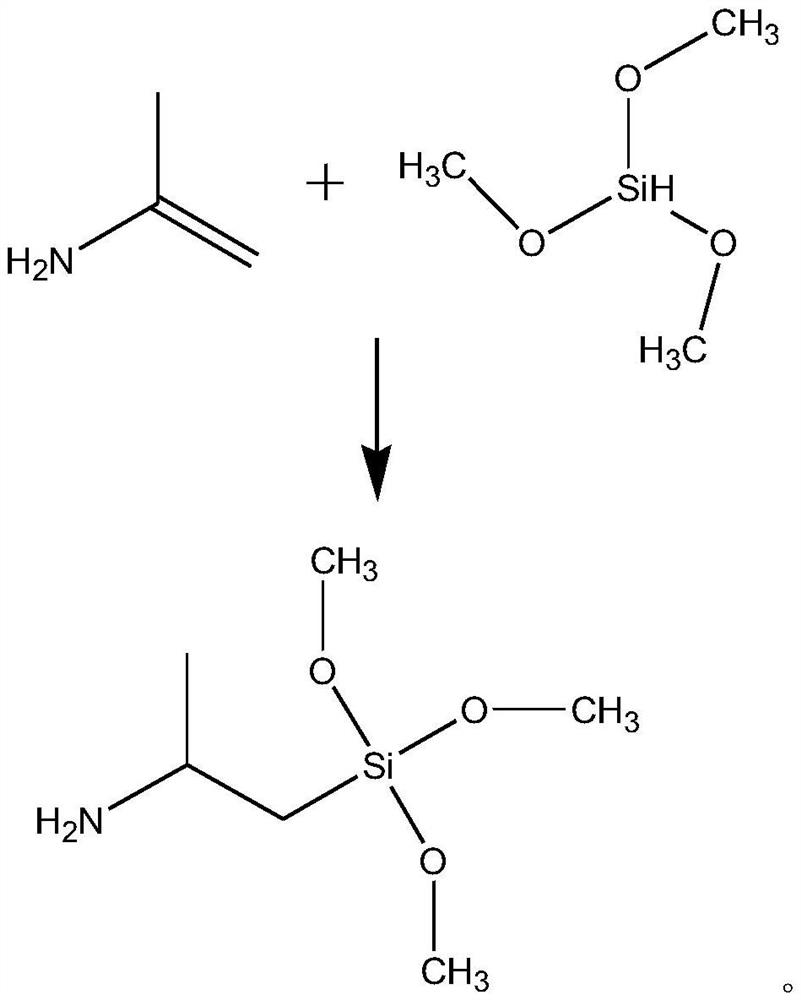

[0042] B. After mixing the polypropylene resin and the conductive filler uniformly in a certain proportion, the conductive masterbatch II is obtained through twin-screw extrusion processing;

[0043] C. melt blending polypropylene resin, stabilizer, nucleating agent, conductive masterbatch 1 and conductive masterbatch 2 to obtain polypropylene particles;

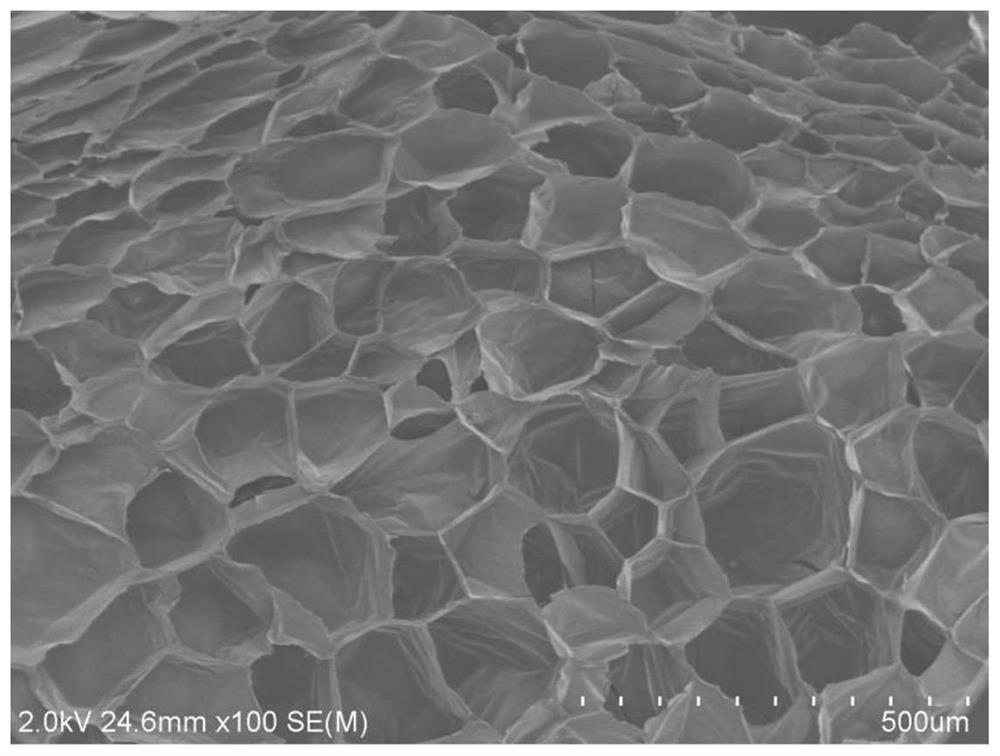

[0044] D. Put the polypropylene particles prepared in step C into the foaming reactor together with the dispersion medium and the dispersing agent, then continuously feed the foaming agent into the foaming reactor and heat and pressurize until the set temperature and pressure are reached , rapid pressure release to...

Embodiment 12

[0058] Example 12 is basically the same as Example 10, except that, after the rapid pressure release in step D, the obtained polypropylene foam beads are kept at 70° C. for 30 minutes;

Embodiment 13

[0059] Example 13 is basically the same as Example 10, except that, after the rapid pressure release in step D, the obtained polypropylene foam beads are kept at 80° C. for 20 minutes;

[0060] After rapid pressure release in Step D in Examples 12 and 13, the obtained polypropylene foam beads were kept at 70-80° C. for 20-30 minutes. The specific operation method is: put the foamed beads just out of the foaming reactor into a spiral insulation pipe, keep the temperature at 70-80°C, the length of the spiral insulation pipe is 30-50m, and the beads are in the During the circulation transmission process, the pipeline is always kept at a constant temperature, and the beads enter the storage bag after circulating in the pipeline for 20-30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com