Water-based cleaning agent and preparation method and application thereof

A technology of water-based cleaning agents and additives, applied in the field of cleaning agents, which can solve the problems of changing the wettability of the metal surface to be plated to water and the inability to remove residual release agents, etc., to achieve a small mass fraction, reduce pressure, and reduce chemical requirements. The effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

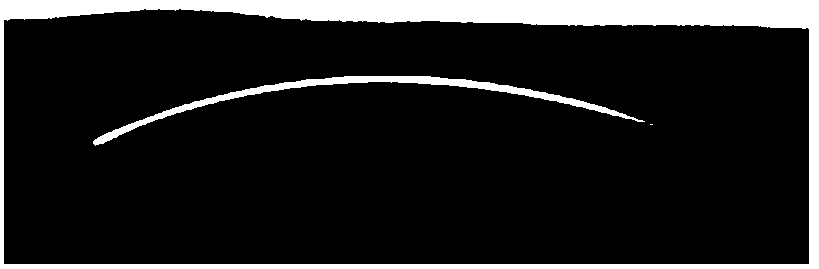

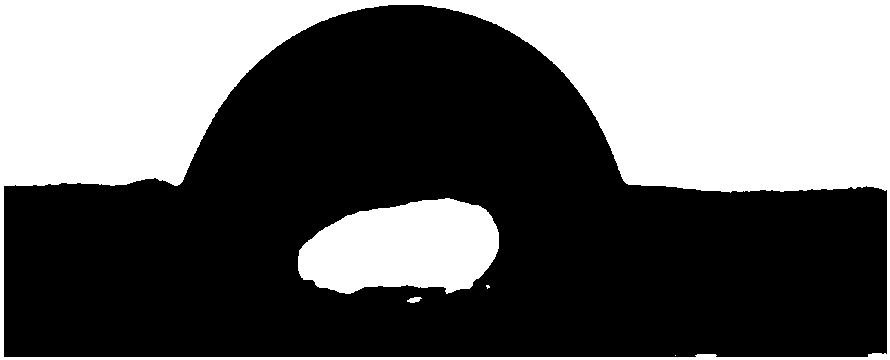

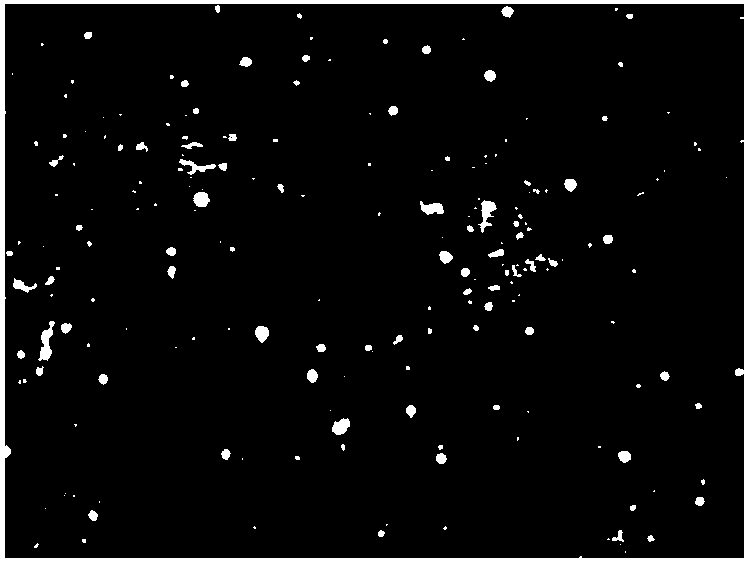

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of water-based cleaning agent, comprises 1.5g AEO-9, the sulfonate (FMES) 8g of fatty acid methyl ester ethoxylate, polyoxyethylene alkylphenol ether 1g, anhydrous sodium metasilicate 10g, 2g sodium hydroxide and 977.5g deionized water, put 977.5ml deionized water into the container, heat to 40°C, add 1.5g AEO-9 into the container and stir for 10min, then add 8g FMES into the container After stirring for 15 minutes, add 1 g of polyoxyethylene alkylphenol ether, 10 g of anhydrous sodium metasilicate and 2 g of sodium hydroxide in sequence, and stir for 10 minutes to obtain a water-based metal cleaning agent.

Embodiment 2

[0034] This embodiment provides a water-based cleaning agent, including 15g AEO-9, FMES 1g, polyoxyethylene alkylphenol ether 3g, anhydrous sodium metasilicate 7g, sodium hydroxide 15g and deionized water 959g, will deionized Put 959ml of ionized water into the container, heat to 90°C, add 15g of AEO-9 into the container and stir for 20min, then add 1g of FMES into the container and stir, after stirring for 10min, add 3g of polyoxyethylene alkylphenol ether in sequence, without Mix 7g of sodium metasilicate in water and 15g of sodium hydroxide, and stir for 15 minutes to obtain a water-based metal cleaning agent.

Embodiment 3

[0036]The present embodiment provides a water-based cleaning agent, including 4g AEO-9, FMES 3g, polyoxyethylene alkylphenol ether 4g, anhydrous sodium metasilicate 3g, sodium hydroxide 9g and deionized water 977g, will deionized Put 977ml of ionic water into the container, heat to 50°C, add 4g of AEO-9 into the container and stir for 12min, then add 3g of FMES into the container and stir, after stirring for 13min, add 4g of polyoxyethylene alkylphenol ether in turn, Mix 3 g of anhydrous sodium metasilicate and 9 g of sodium hydroxide, and stir for 12 minutes to obtain a water-based metal cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com