Preparation method of release paper with double-sided film

A release paper and coating technology, applied in paper, papermaking, paper coating and other directions, can solve the problems of non-wear resistance, poor moisture resistance, limited use range of release paper, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a release paper with double-sided coating, comprising the following preparation steps:

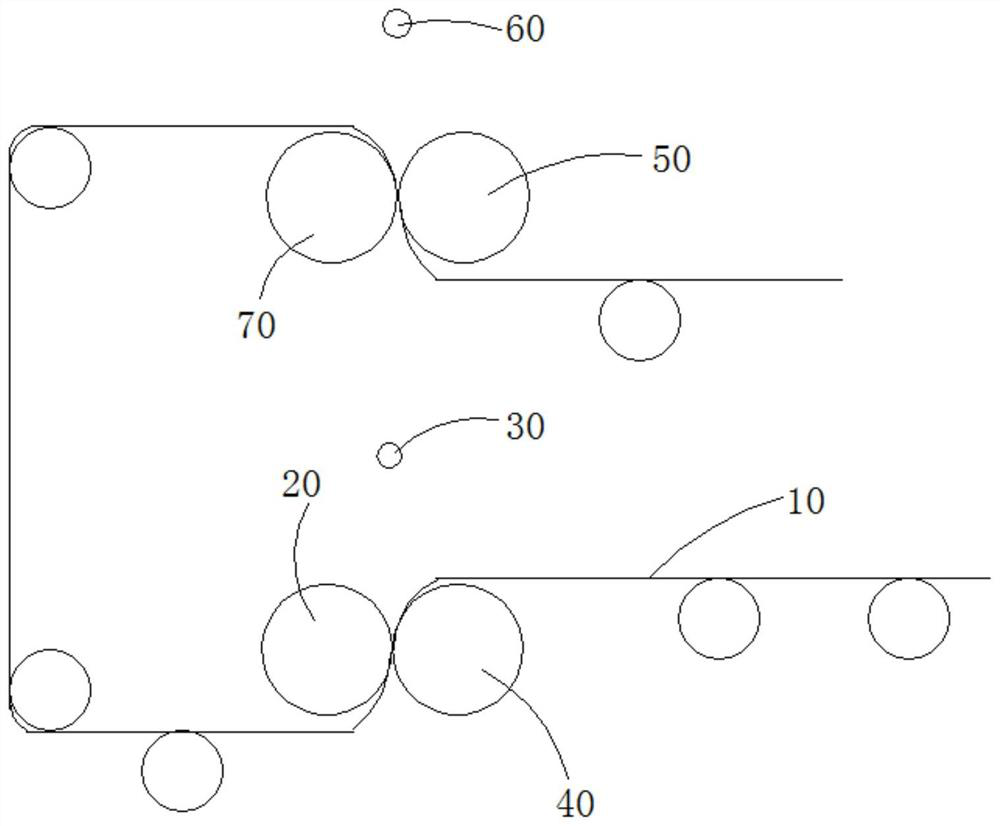

[0027] S1: Provide the base paper 10, the first coating material, the second coating material and the coating machine; the base paper 10 has a front surface and a back surface; The first coating head 30 on the upper end of the patterned roller 20, the first auxiliary roller 40 in contact with the surface of the first patterned roller 20, the second patterned roller 50 positioned at the rear end of the first patterned roller 20, and the first patterned roller 50 connected to the first patterned roller 20. The second auxiliary roller 70 that the surface of the two embossed rollers 50 contacts, and the second coating head 60 positioned at the upper end of the second embossed rollers 50, such as figure 1 As shown; the first coating material includes the following components by weight: 90-94 parts of polypropylene, 3-5 parts of polyethylene, ...

Embodiment 1

[0034] A preparation method of a release paper with a double-sided coating, comprising the following preparation steps:

[0035] S1: Provide the base paper 10, the first coating material, the second coating material and the coating machine; the base paper 10 has a front surface and a back surface; The first coating head 30 on the upper end of the patterned roller 20, the first auxiliary roller 40 in contact with the surface of the first patterned roller 20, the second patterned roller 50 positioned at the rear end of the first patterned roller 20, and the first patterned roller 50 connected to the first patterned roller 20. The second auxiliary roller 70 contacted by the surface of the second patterned roller 50, and the second coating head 60 located at the upper end of the second patterned roller 50;

[0036] S2: Place the base paper 10 between the first patterned roller 20 and the first auxiliary roller 40, pour the first coating material between the first patterned roller ...

Embodiment 2

[0039] A preparation method of a release paper with a double-sided coating, comprising the following preparation steps:

[0040] S1: Provide the base paper 10, the first coating material, the second coating material and the coating machine; the base paper 10 has a front surface and a back surface; The first coating head 30 on the upper end of the patterned roller 20, the first auxiliary roller 40 in contact with the surface of the first patterned roller 20, the second patterned roller 50 positioned at the rear end of the first patterned roller 20, and the first patterned roller 50 connected to the first patterned roller 20. The second auxiliary roller 70 contacted by the surface of the second patterned roller 50, and the second coating head 60 located at the upper end of the second patterned roller 50;

[0041] S2: Place the base paper 10 between the first patterned roller 20 and the first auxiliary roller 40, pour the first coating material between the first patterned roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com