Off-line debugging test system for tipping paper deviation rectifying device

A testing system and tipping paper technology, applied in transportation and packaging, strip winding, thin material handling, etc., can solve problems such as poor adjustment accuracy and inability to monitor the status of tipping paper in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

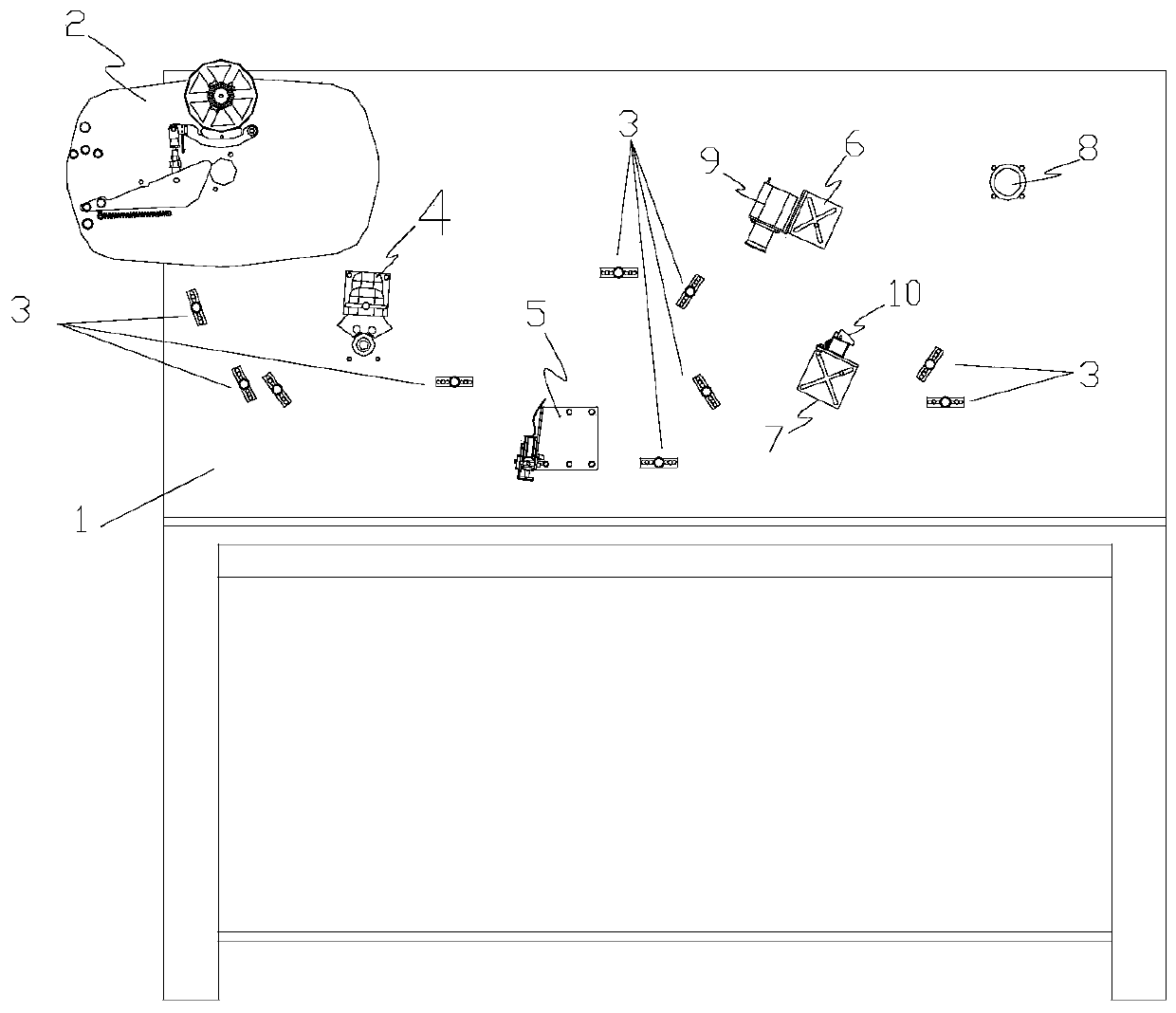

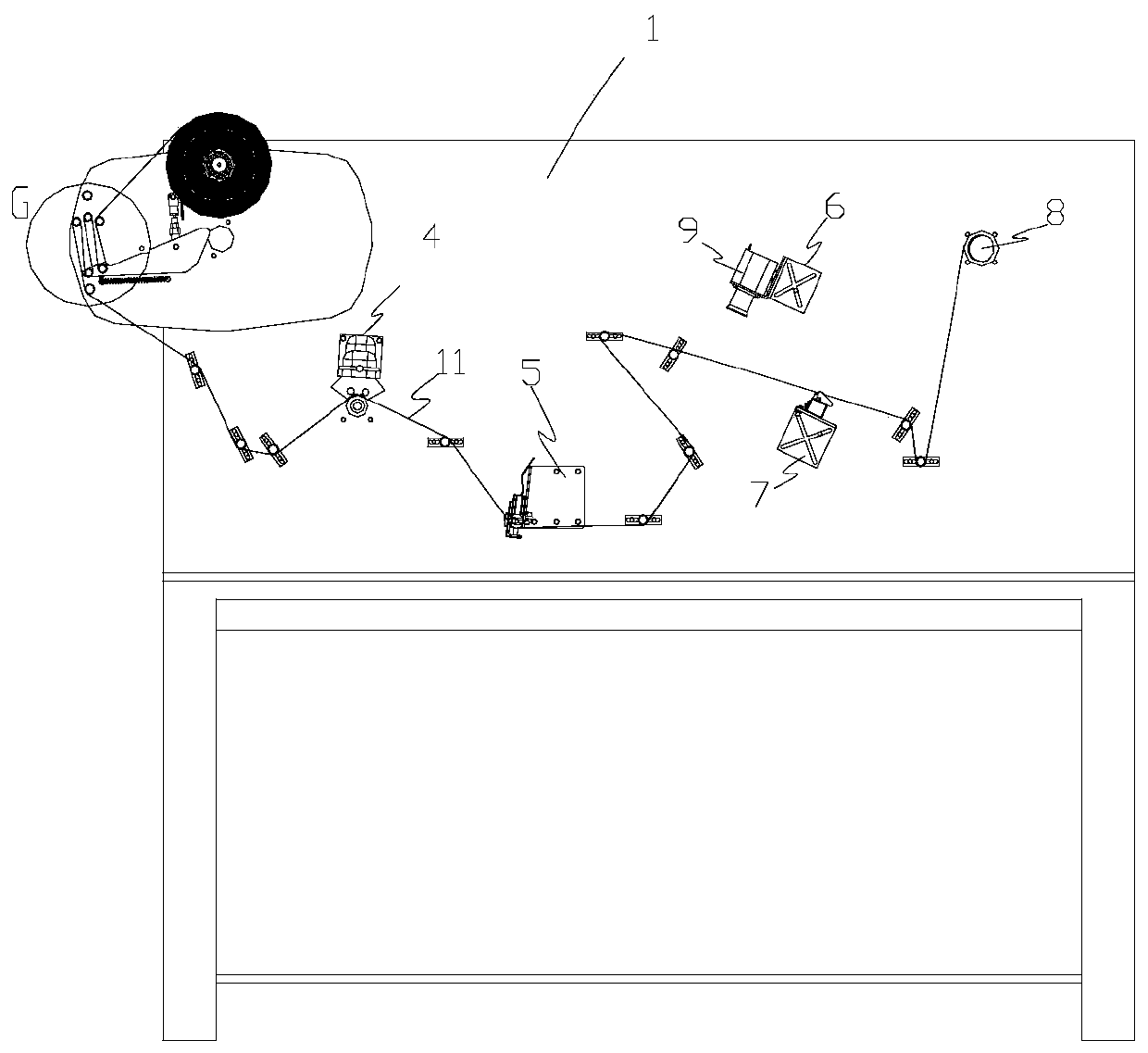

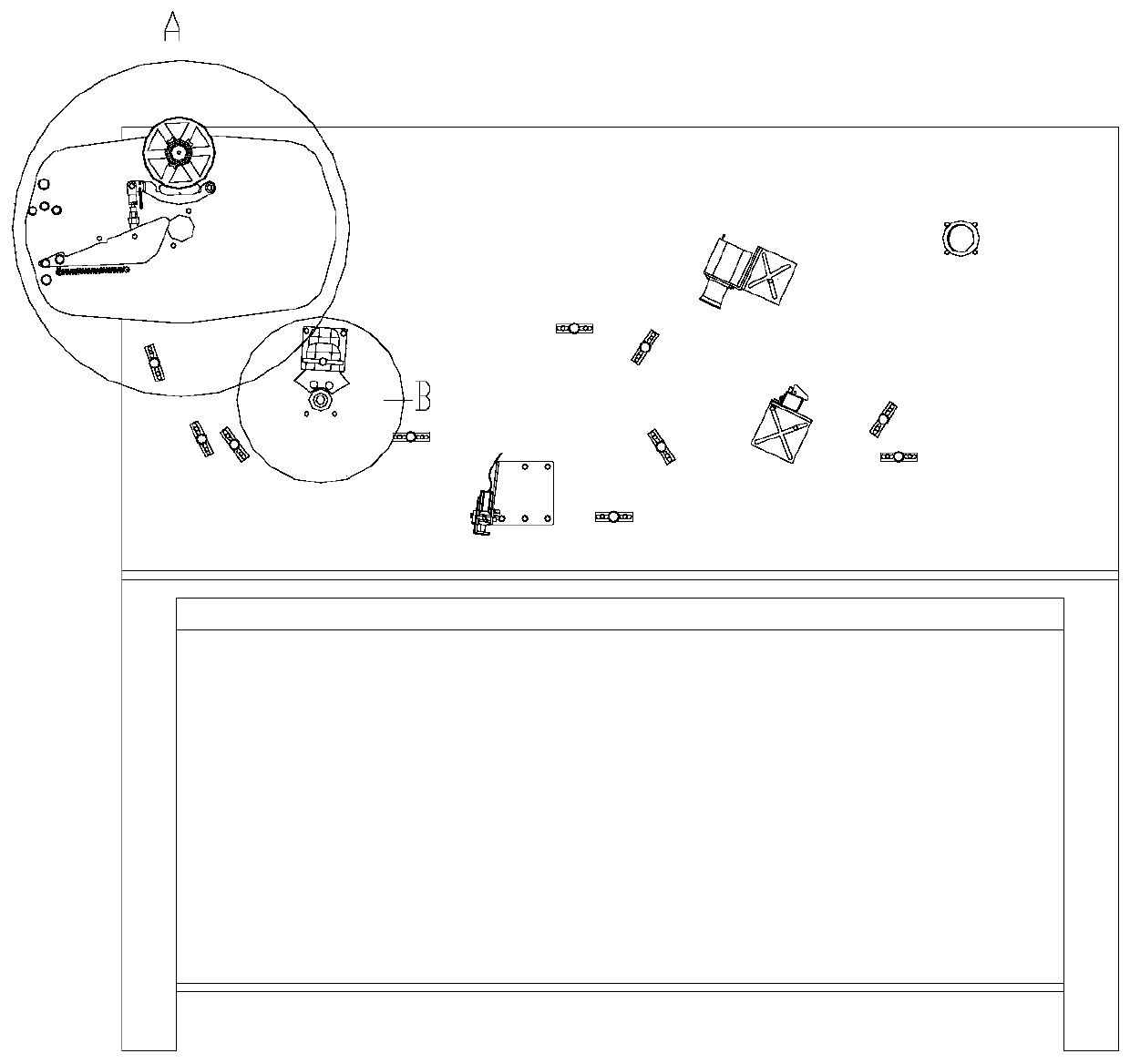

[0111]An off-line debugging and testing system of a tipping paper deviation correction device, including a mechanical part and a control part, the structure of the mechanical part is as follows Figure 1-15 shown.

[0112] The overall structure of the mechanical part of the test system is as follows: Figure 1 to Figure 6 As shown, it includes the test table 1 and the tipping paper unwinding mechanism 2 installed on the test table 1, the tape conveying mechanism 3, the paper pulling mechanism 4, the tipping paper offset actuator 5, and the installation of the offset detector. Mechanism 6, offset adjuster installation mechanism 7 and paper tape circulation winding mechanism 8.

[0113] The test table includes a vertical wall and a bracket supporting the vertical wall. One side of the wall is the installation surface, and the other side is the back. The tipping paper unwinding mechanism 2, the paper tape conveying mechanism 3, the paper pulling mechanism 4, the water The paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com