A processing device and working method for single-stroke sawing hard stone

A processing device and single-stroke technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as short service life, impact in cutting, wear and tear, etc., to reduce wear, save energy consumption, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

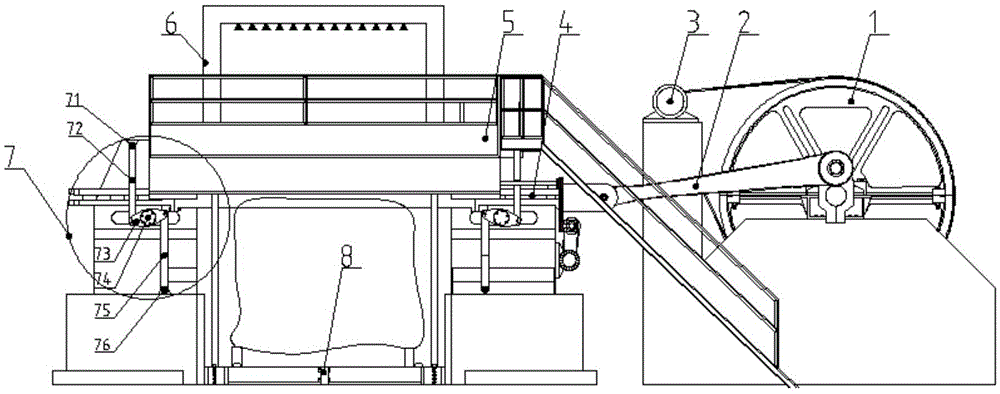

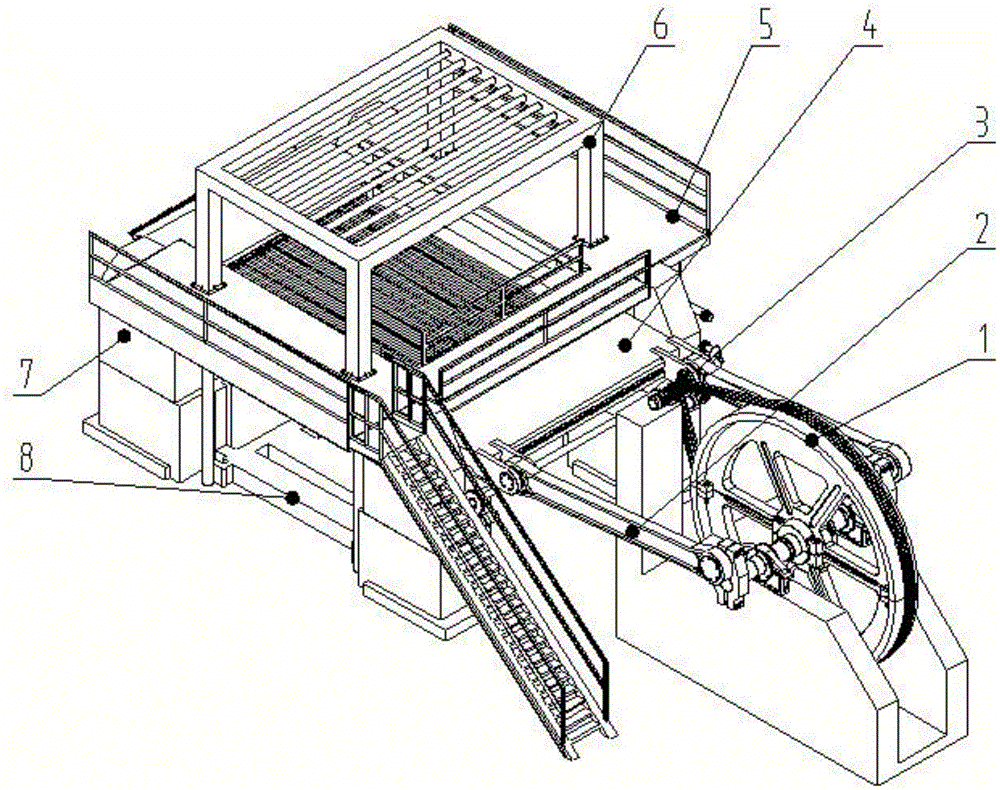

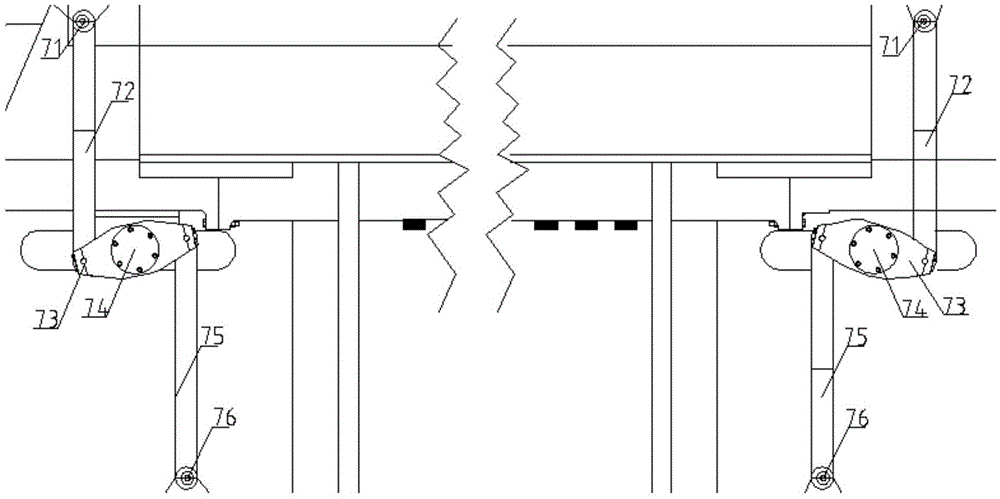

[0035] like figure 1 Shown is a single-stroke sawing device for ultra-hard stone related to the present invention, including flywheel 1, crank connecting rod 2, main motor 3, saw frame unit 4 (saw frame and diamond saw blade), frame 5, water spray Cooling device 6, hinge guide mechanism 7, block truck and stone jacking device 8. Both the saw frame unit 4 and the hinge guide mechanism 7 are arranged on the frame 5 . The hinge guide mechanism 7 includes a swing body 73 , an upper link 72 , a lower link 75 , an upper link pivot shaft 71 , a lower link pivot shaft 76 and a swing body central axis 74 . One end where the upper and lower connecting rods are connected to the frame has a certain eccentricity relative to its own original central pivot, and the other end is normally hinged with the swing body. One end of the central axis of the oscillating body is pivotally connected to the saw frame unit, and the other end is hingedly fitted with the oscillating body.

[0036] like ...

Embodiment 2

[0041] The difference from Embodiment 1 is that the upper and lower links 72, 75 of the hinge guide mechanism 7 are connected to the frame 5, and the upper link 72 is eccentric to the left, and the lower link 75 is eccentric to the right. At this time, the hinge The whole organization shows a left deflection trend. When the connecting rod swings relative to the frame, the eccentric section makes the saw frame in a cutting state during a stroke (including reversing) away from the flywheel end, and a non-cutting state during a stroke (including reversing) near the flywheel end. When the connecting rod swings to the left relative to the frame, the saw frame unit moves leftward and downward relative to the frame saw machine; when the connecting rod swings to the right, the hinge guide mechanism unit drives the saw frame unit to move rightward relative to the frame saw machine and move upwards. The eccentricity at this time makes the overall saw frame of the saw machine move in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com