Warehouse logistics carrying robot

A technology for handling robots and warehousing and logistics, which is applied in the field of logistics and handling. It can solve the problems of time-consuming external disassembly of the motor wheel, reduce the safety of logistics and handling, and poor installation stability, and achieve the effects of easy replacement, improved safety, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

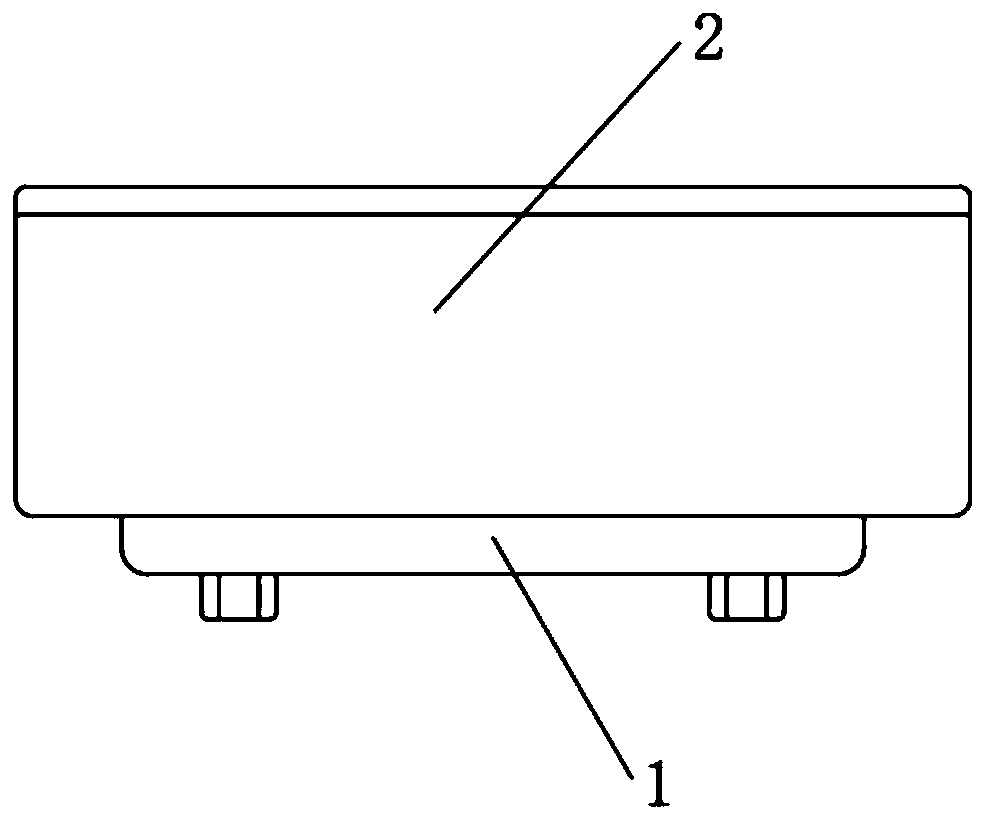

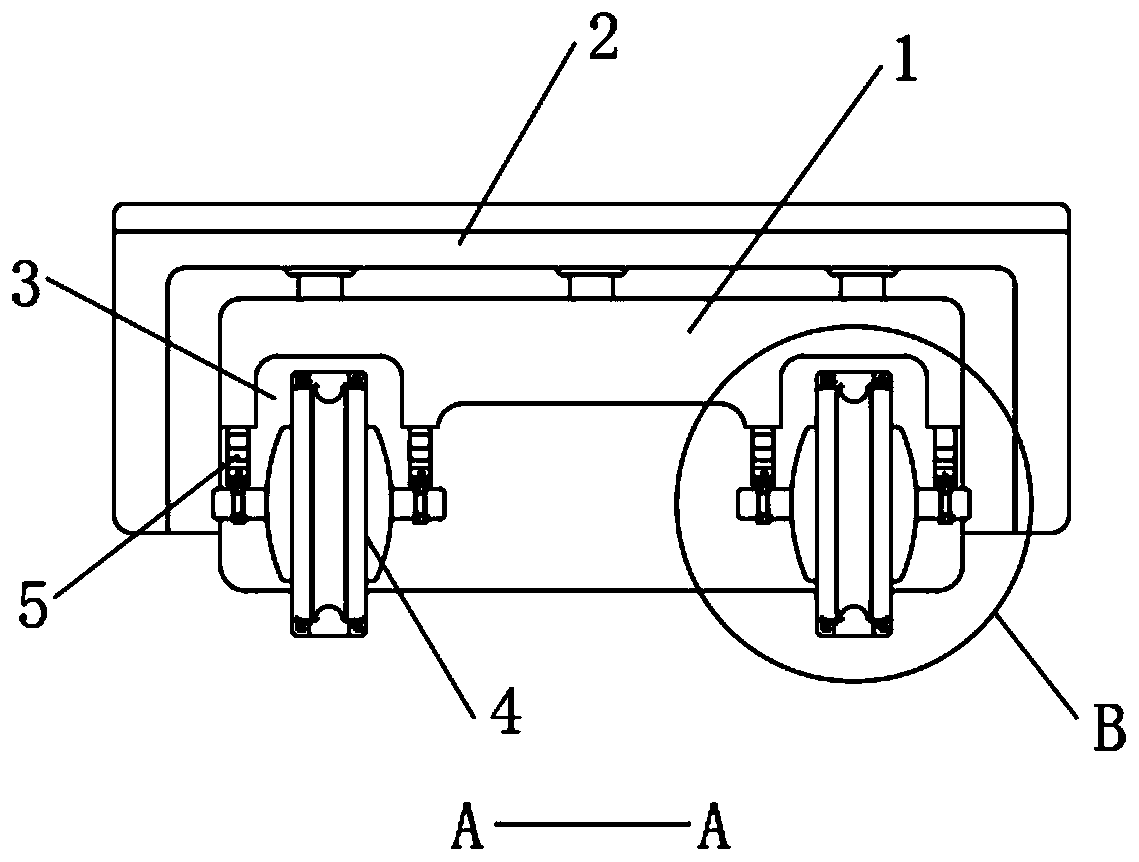

[0023] see Figure 1-5 , the present invention provides the following technical solutions: a warehousing logistics handling robot, including a drive base 1 and a tray 2, the tray 2 is installed above the drive base 1, the lower surface of the drive base 1 is provided with a wheel groove 3, and the inside of the wheel groove 3 The drive motor wheel 4 is installed, and the output shaft at both ends of the drive motor wheel 4 is integrally formed with a rotating shaft 45, and the surface of the rotating shaft 45 is provided with a limiting groove 46, and the outside of the limiting groove 46 is sleeved with a connecting clamp 6, which connects the clamping plate 6. Both ends are fixed with a leaf spring 5 by bolts, and the two ends of the leaf spring 5 are fixed on the surface of the wheel groove 3 by bolts.

[0024] In this embodiment, the rotating shaft 45 is connected to the leaf spring 5 through the connecting clamp 6, and the connecting clamp 6 is set outside the limit groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com