Net-belt cloth piling wheel device

A mesh belt and cloth stacking technology, which is applied in the field of mesh belt cloth stacking wheel devices, can solve the problems of easy overturning and pressing of cloth stacking, uneven stacking, and low production efficiency, so as to achieve uniform stacking volume and reduce production cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

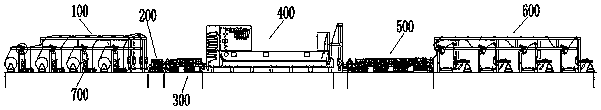

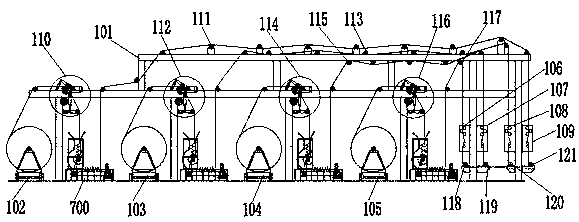

[0047] see Figure 1-Figure 25 , a multi-layer refining and bleaching production line related to the present invention, comprising a multi-layer cloth feeding mechanism 100, a pre-washing box 200, a multiple padding mechanism 300, a mesh belt steaming box 400, a water washing mechanism 500, a multi-layer cloth outlet mechanism 600, Sewage treatment system, wherein, multi-layer cloth feeding mechanism 100, pre-washing box 200, multiple padding mechanism 300, mesh belt steaming box 400, water washing mechanism 500, and multi-layer cloth outlet mechanism 600 are arranged in sequence from left to right;

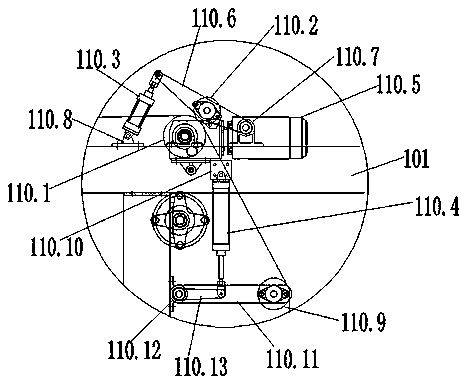

[0048] The multi-layer cloth feeding mechanism 100 includes a multi-layer cloth feeding mechanism frame 101, and the left section of the multi-layer cloth feeding mechanism frame 101 is provided with a first unwinding device 102, a second Unwind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com