Wiping-free car washing liquid

A car wash liquid and wipe-free technology, which is applied in the field of car wash liquid, can solve problems such as rust, cracks, and discoloration, and achieve the effects of saving water and electricity resources, reducing environmental pollution, and improving car washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0023] A kind of wipe-free car washing liquid, comprising the following components by mass percentage:

[0024] Chelating agent 10%;

[0025] Anionic surfactant 8%;

[0026] Non-ionic surfactant 1%;

[0027] Organic solvent 2%;

[0028] Organic phosphonates 3%;

[0029] The balance is water.

[0030] Further, the chelating agent is tetrasodium hydroxyethylidene diphosphonate.

[0031] Further, the anionic surfactant is sodium lauryl sulfate.

[0032] Further, the nonionic surfactant is isooctyl alcohol polyoxyethylene ether.

[0033] Further, the organic solvent is propylene glycol phenyl ether.

[0034] Further, the organic phosphonate is aminotrimethylene phosphonic acid.

[0035] When in use, the wipe-free car wash liquid of this embodiment is diluted with water at a ratio of 1:80-100 and stirred evenly to form a mixed liquid, and the mixed liquid is evenly sprayed onto the vehicle body and wheel hubs with a foam machine. Using a car washing machine above 5MPa for ...

specific Embodiment 2

[0037] A kind of wipe-free car washing liquid, comprising the following components by mass percentage:

[0038] Chelating agent 25%;

[0039] Anionic surfactant 20%;

[0040] Non-ionic surfactant 3%;

[0041] Organic solvent 6%;

[0042] Organic phosphonates 10%;

[0043] The balance is water.

[0044] Further, the chelating agent is sodium tripolyphosphate.

[0045] Further, the anionic surfactant is fatty alcohol polyoxyethylene ether sodium sulfate.

[0046] Further, the nonionic surfactant is isooctyl alcohol polyoxyethylene ether.

[0047] Further, the organic solvent is ethoxydiglycol.

[0048] Further, the organic phosphonate is polyamino polyether methylene phosphonic acid.

specific Embodiment 3

[0050] A kind of wipe-free car washing liquid, comprising the following components by mass percentage:

[0051] Chelating agent 20%;

[0052] Anionic surfactant 15%;

[0053] Non-ionic surfactant 2%;

[0054] Organic solvent 4%;

[0055] Organic phosphonates 8%;

[0056] The balance is water.

[0057] Further, the chelating agent is disodium edetate.

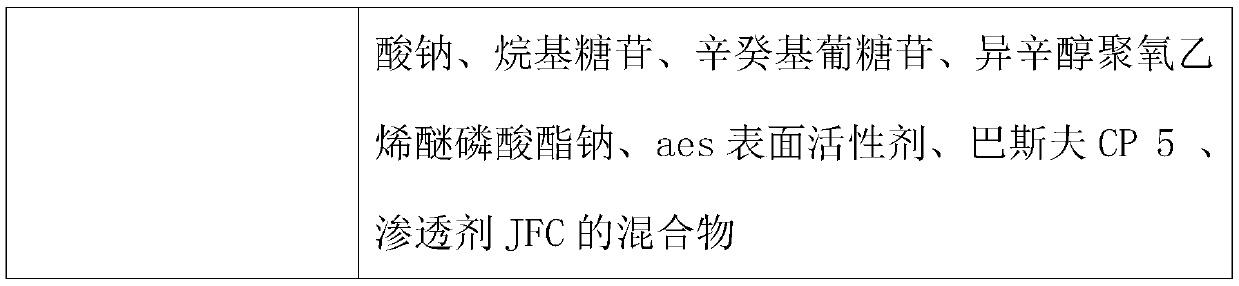

[0058] Further, the anionic surfactant is an alkyl glycoside.

[0059] Further, the nonionic surfactant is isooctyl alcohol polyoxyethylene ether.

[0060] Further, the organic solvent is propylene glycol butyl ether.

[0061] Further, the organic phosphonate is equal mass of aminotrimethylene phosphonic acid and polyaminopolyether methylene phosphonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com