Method for reducing odor of mercaptocarboxylic acid ester

A technology of polymercapto carboxylate and mercapto carboxylate, which is applied in the chemical industry, can solve problems such as unpleasant odor of products, and achieve the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

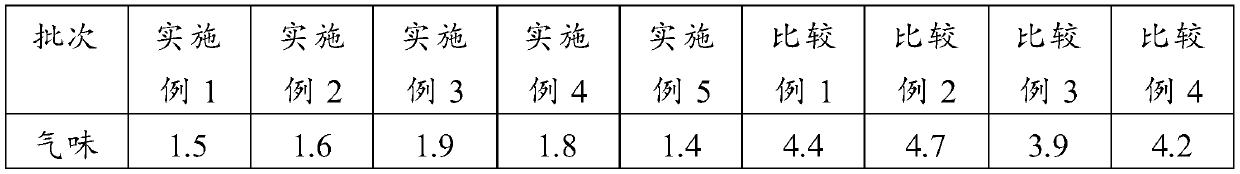

Examples

Embodiment 1

[0059] In a 1000ml four-neck flask equipped with a mechanical stirrer, a thermometer, and a reflux water separator, add 68.8g (0.50mol) of pentaerythritol, 214.1g (2.0mol) of 3-mercaptopropionic acid, 2.8g of catalyst methanesulfonic acid, and cyclohexane Alkanes 140.0g, heat reflux water separation, stop reaction after reaching theoretical water yield. Put the reacted mixture in a separatory funnel, divide the lower layer product into a four-necked flask, add 246.0 g of 3% sodium sulfite aqueous solution, stir for 20 minutes at 50-60° C., and transfer it to a separatory funnel for separation. layer for 10 minutes, divide the crude product of the lower layer into a four-neck flask, add 240.0 g of deionized water, stir at 50°C for 10 minutes, transfer to a separatory funnel to separate layers, and then perform a second water wash to obtain a washed crude product. Distilled for 2 hours under the conditions of pressure ≤ 5kPa, nitrogen flow rate of 8.0L / h / h·kg crude product, and ...

Embodiment 2

[0061] In a 1000ml four-necked flask equipped with mechanical stirring, a thermometer, and a negative pressure condensing device, add 68.8g (0.50mol) of pentaerythritol, 186.1g (2.0mol) of mercaptoacetic acid, 2.5g of catalyst methanesulfonic acid, and 127.0g of cyclohexane , heating to reflux to separate water, and stop the reaction after reaching the theoretical water output. Place the reacted mixture in a separatory funnel, divide the lower layer product into a four-necked flask, add 219.0 g of a 3% sodium sulfite aqueous solution configured by recovering water from Example 1, stir at 50-60° C. for 20 minutes, turn to Put into the separatory funnel to carry out layering for 10 minutes, divide the crude product of the lower layer into the four-necked flask, add 219.0g of the recovered water of Example 1, stir at 50°C for 10 minutes, transfer to the separatory funnel for layering, and then carry out the second Washing twice to obtain the washed crude product. Distilled for 2...

Embodiment 3

[0063] In a 1000ml four-necked flask equipped with mechanical stirring, a thermometer, and a negative pressure condensing device, add 67.7g (0.50mol) of trimethylolpropane, 160.7g (1.5mol) of 3-mercaptopropionic acid, and 2.3 g of catalyst methanesulfonic acid. g, cyclohexane 119.0g, heated to reflux to separate water, stop the reaction after reaching the theoretical water yield. Place the reacted mixture in a separatory funnel, divide the lower layer product into a four-necked flask, add 201.4 g of 2% sodium sulfite aqueous solution configured by recovering water in Example 2, stir at 50-60°C for 20 minutes, turn to Put into the separatory funnel to carry out stratification for 10 minutes, divide the crude product in the lower layer into the four-necked flask, add 201.4g of the recovered water of Example 2, stir at 50°C for 10 minutes, transfer to the separatory funnel for layering, and then carry out the second Washing twice to obtain the washed crude product. Distilled for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com