Method for refining long-chain dibasic acid under protection of inert gas

A long-chain dibasic acid and inert gas technology, which is applied in the field of refining normal long-chain dibasic acids under the protection of inert gas, can solve the problems of high residual acetic acid, limited application range, and high solvent residue, so as to improve utilization efficiency, Improve product quality, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

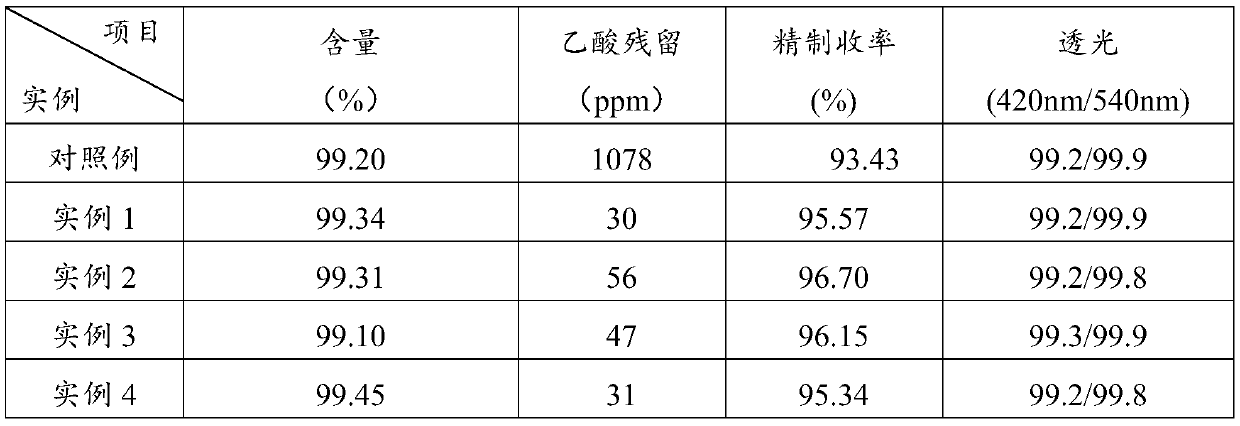

Examples

example 1

[0059] A kind of refining method of dodecanedioic acid of the present invention of example 1

[0060] Take 500kg of crude dodecanedibasic acid (loss on drying <0.5%), add 0.8% activated carbon to 2000kg of 82% acetic acid solution, stir and heat up to 84°C, and decolorize for 60 minutes. The dodecanedibasic acid solution obtained by filtration enters the crystallization tank, stirs and controls the cooling rate to drop 3-15°C per hour, and slowly cools down to 22°C. The obtained dodecanedibasic acid was filtered, resuspended by adding 3000 kg of water, and the system was heated to 120°C under the protection of an inert nitrogen gas, kept for 50 minutes, slowly cooled (by 8°C per hour) to room temperature, separated and dried to obtain twelve Carbon dibasic acid products (loss on drying not more than 1%).

example 2

[0061] Example 2 The refining method of a kind of dodecanedioic acid of the present invention

[0062] Take 500kg of crude dodecanedibasic acid (loss on drying <0.5%), add 0.6% activated carbon into 2000kg of 83% acetic acid solution, stir and heat up to 85°C, and the decolorization time is 70min. The dibasic acid solution obtained by filtration enters the crystallization tank, stirs and controls the cooling rate to drop 3-15°C per hour, and slowly cools down to crystallize in the crystallization tank to 21°C. Filtrate the obtained dodecanedibasic acid, add 3000kg of deionized water to resuspend, the system is under the protection of nitrogen inert gas, heat up to 135°C, keep warm for 60min, slowly cool down (8°C per hour) to room temperature, separate and dry Dodecanedibasic acid product (loss on drying not more than 1%) is obtained.

example 3

[0063] Example 3 The refining method of a kind of tridecanedioic acid of the present invention

[0064] Take 500kg of crude tridecanedibasic acid (loss on drying < 0.5%), add 0.7% activated carbon into 2500kg of 80% acetic acid solution, stir and heat up to 82°C, and the decolorization time is 70min. The dibasic acid solution obtained by filtration enters the crystallization tank, stirs and controls the cooling rate to drop 3-15°C per hour, and slowly cools down to crystallize in the crystallization tank to 22°C. The tridecanedibasic acid obtained by filtration was resuspended by adding 3000 kg of deionized water. Under the protection of nitrogen inert gas, the system was heated to 120°C, kept for 70 minutes, cooled (by 8°C per hour) to room temperature, separated and dried to obtain Tridecane dibasic acid product (loss on drying not more than 1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com