Reinforcing agent for pervious concrete as well as preparation method and construction process of reinforcing agent

A technology of permeable concrete and construction technology, which is applied to cohesive pavement paved on site, buildings, roads, etc., which can solve the problems of water permeability, inconsistent vegetation, swaying surface stones, poor water permeability, etc., to avoid surface stones Effects of sloshing or dropping, fast project progress, and excellent continuous porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

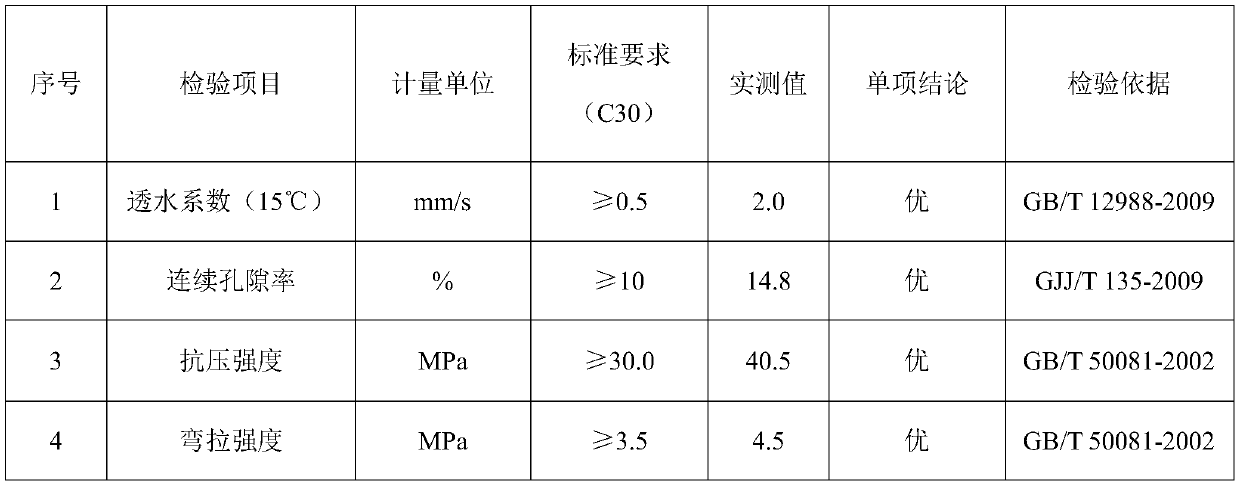

Examples

Embodiment 1

[0039] The reinforcing agent for permeable concrete of the present embodiment includes the following components by weight: 50 parts of nano-scale silicon powder, 15 parts of water reducing agent, 2 parts of cellulose, 8 parts of calcium sulfate whiskers, 5 parts of trisodium phosphate, 1.5 parts of calcium carboxylate, 6 parts of alkali metal carbonate and 2 parts of formamide.

[0040] Among them, the shape of nano-scale silicon powder is spherical, and the particle size is 1-100nm; the water reducer is polycarboxylate high-efficiency water reducer, and the cellulose is methyl cellulose or ethyl cellulose; calcium carboxylate is selected from One or a mixture of calcium formate, calcium acetate or calcium acrylate; alkali metal carbonates are selected from K 2 CO 3 , Li 2 CO 3 and Na 2 CO 3 one or a mixture of several.

[0041] The preparation method of this reinforcing agent comprises the steps:

[0042] (1) take each raw material by proportioning, for subsequent use;...

Embodiment 2

[0046] The reinforcing agent for permeable concrete of the present embodiment includes the following components by weight: 70 parts of nano-scale silicon powder, 12 parts of water reducing agent, 3 parts of cellulose, 9 parts of calcium sulfate whiskers, 7 parts of trisodium phosphate, 3 parts of calcium carboxylate, 4 parts of alkali metal carbonate and 1 part of formamide.

[0047] Among them, the shape of nano-scale silicon powder is spherical, and the particle size is 1-100nm; the water reducer is polycarboxylate high-efficiency water reducer, and the cellulose is methyl cellulose or ethyl cellulose; calcium carboxylate is selected from One or a mixture of calcium formate, calcium acetate or calcium acrylate; alkali metal carbonates are selected from K 2 CO 3 , Li 2 CO 3 and Na 2 CO 3 one or a mixture of several.

[0048] The preparation method of this reinforcing agent comprises the steps:

[0049] (1) take each raw material by proportioning, for subsequent use;

...

Embodiment 3

[0053] The reinforcing agent for permeable concrete of the present embodiment includes the following components by weight: 80 parts of nano-scale silicon powder, 10 parts of water reducing agent, 4 parts of cellulose, 10 parts of calcium sulfate whiskers, 8 parts of trisodium phosphate, 5 parts of calcium carboxylate, 2 parts of alkali metal carbonate and 0.5 part of formamide.

[0054] Among them, the shape of nano-scale silicon powder is spherical, and the particle size is 1-100nm; the water reducer is polycarboxylate high-efficiency water reducer, and the cellulose is methyl cellulose or ethyl cellulose; calcium carboxylate is selected from One or a mixture of calcium formate, calcium acetate or calcium acrylate; alkali metal carbonates are selected from K 2 CO 3 , Li 2 CO 3 and Na 2 CO 3 one or a mixture of several.

[0055] The preparation method of this reinforcing agent comprises the steps:

[0056] (1) take each raw material by proportioning, for subsequent use;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com