Automatic pushing type waste material collecting device for gear machining

A waste collection and automatic technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of broken waste materials being brought out and falling into the ground, etc., to achieve reasonable guiding rebound characteristics, reasonable structure, and convenient Take out the collected effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

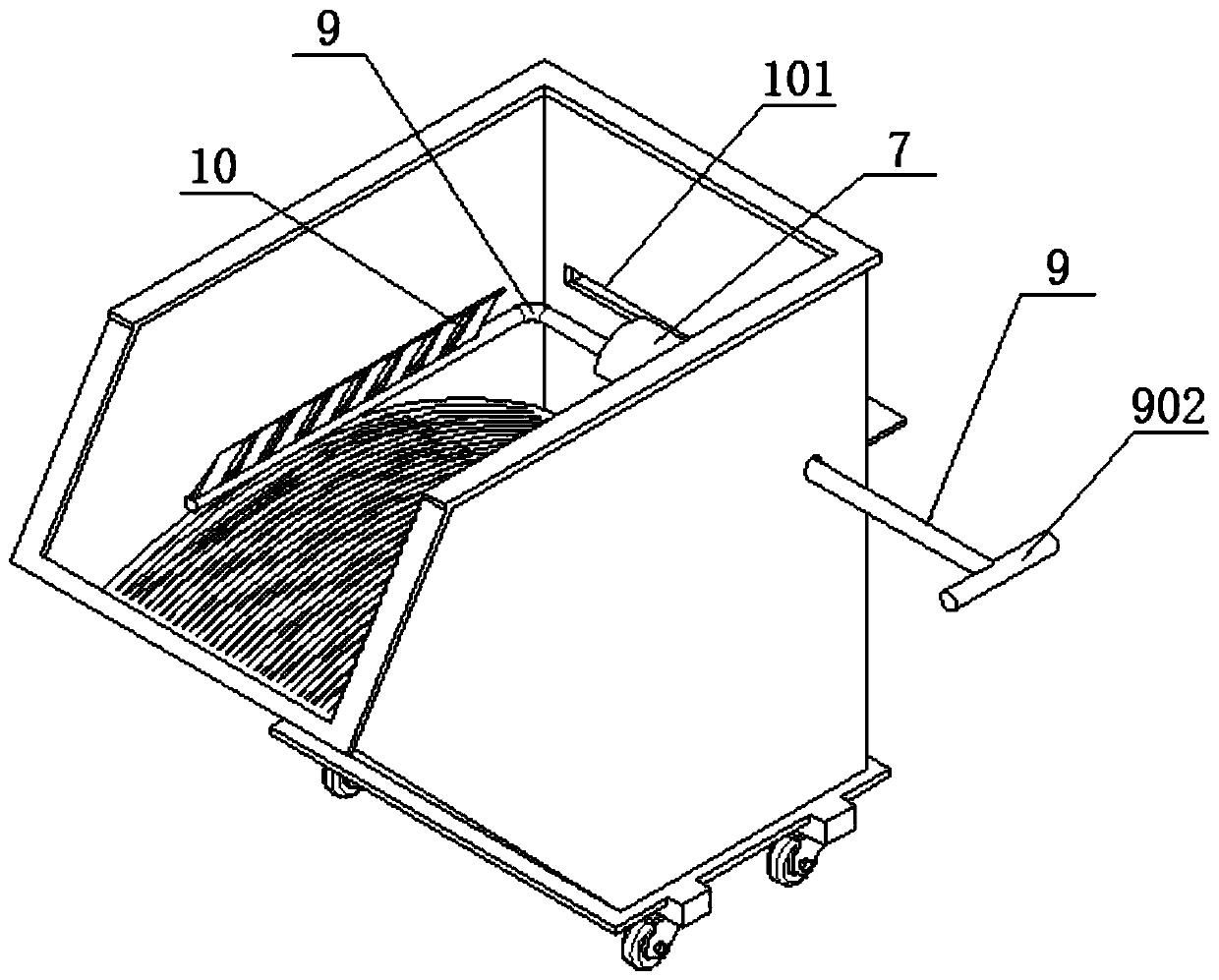

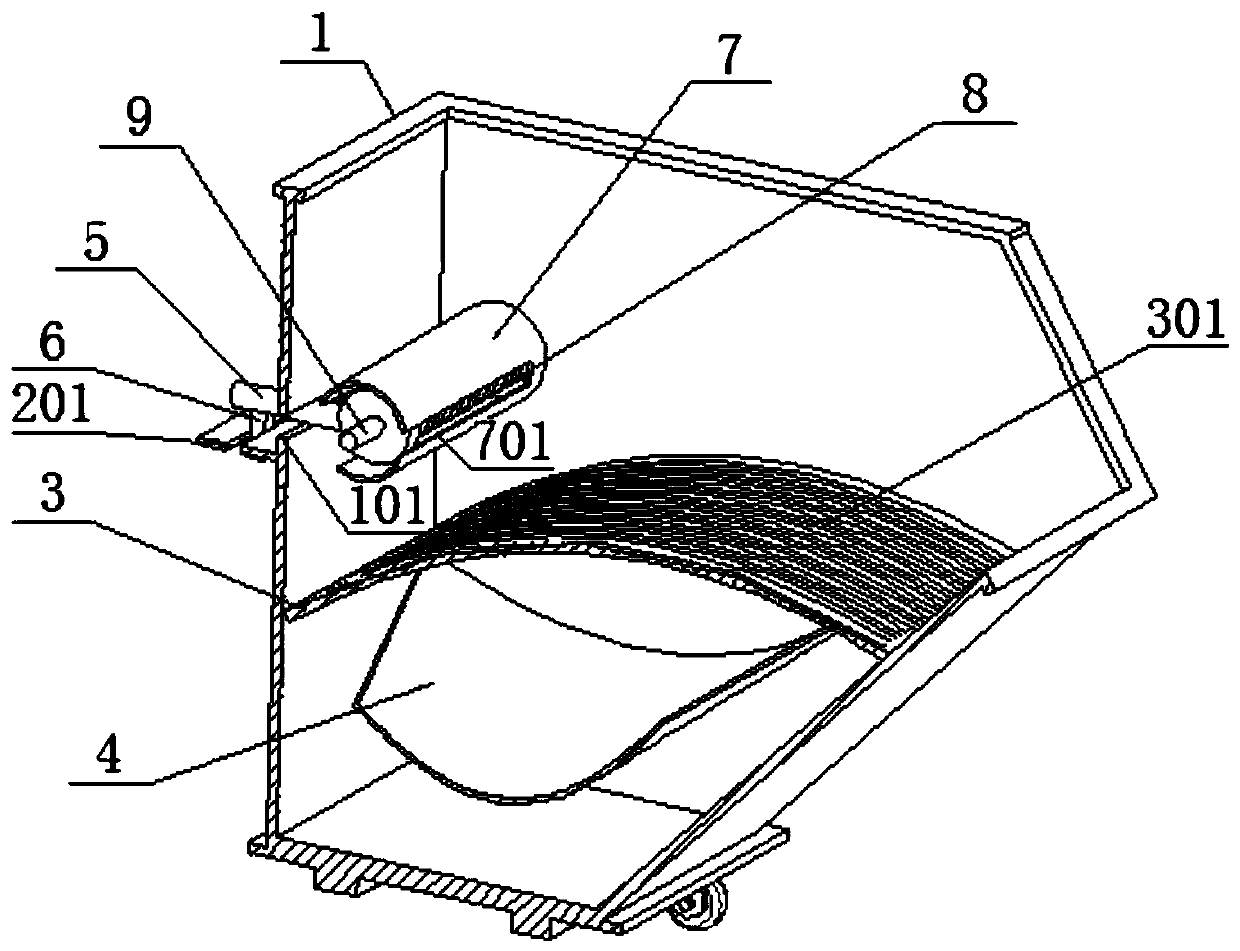

[0028] as attached figure 1 to attach Figure 9 Shown:

[0029] The present invention provides an automatic push-type waste collection device based on gear processing, including: a recovery cabin 1, a first guide groove 101, a discharge port 102, a guide edge 103, a side plate 2, a second guide groove 201, Distribution plate 3, drain 301, discharge plate 4, side extension rod 5, vertical rod 6, stop sleeve 7, third guide groove 701, spring 8, pull rod 9, stop ring 901, pull handle 902, pressure plate 10, Functional seat 11, push groove 1101, extrusion frame 1102, extrusion rod 1103, strength spring 1104, storage groove 1105 and pressure plate 1106; the recovery cabin 1 is a bucket cavity structure, and one side thereof is provided with a discharge port 102 , and there is also a discharge plate 4 welded at the bottom of the inner chamber of the recovery cabin 1, and the discharge end of the discharge plate 4 protrudes outwards from the discharge port 102; the left end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com