Nitrogen-doped carbon material supported by cobalt nitride and preparation method thereof

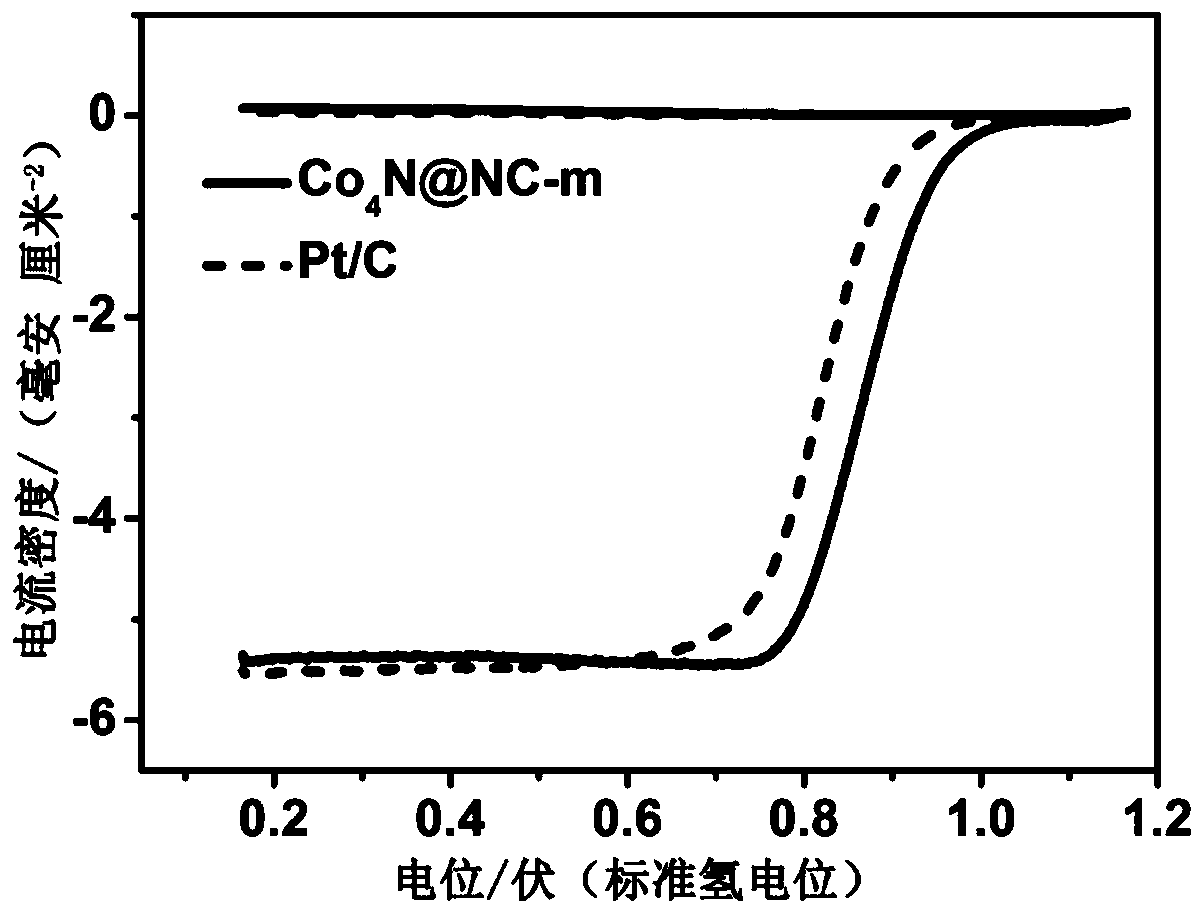

A nitrogen-doped carbon and cobalt nitride technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as poor dispersion and uncontrollable composite material morphology, and achieve uniform metal dispersion , excellent electrocatalytic performance, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention firstly provides a method for preparing a cobalt nitride-supported nitrogen-doped carbon material, which specifically includes the following steps:

[0027] Step 1. Preparation of ZnO core-shell structure precursor

[0028] 1) Dissolve polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123), trishydroxymethylaminomethane (Tris) and ZnO nanospheres in water, stir evenly, and obtain a mixed liquid;

[0029] 2) Dopamine is dissolved in deionized water, then added to the above mixed solution, stirred for reaction, and then the reaction solution is centrifuged, washed and dried to obtain a ZnO core-shell structure precursor; the reaction temperature is preferably room temperature, and the reaction The time is preferably 1 to 3 hours;

[0030] The mass ratio of the polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, trishydroxymethylaminomethane, ZnO nanospheres and dopamine is preferably (0.05~0.20...

Embodiment 1

[0039] 1. Preparation of ZnO core-shell structure precursor

[0040] 1) Dissolve 0.08g P123, 0.12g Tris and 0.10g ZnO nanospheres in water, stir and mix evenly to obtain a mixed aqueous solution;

[0041] 2) 0.40 g of dopamine was dissolved in deionized water, added to the above solution, and stirred and reacted at room temperature for 1 h;

[0042] 3) The reacted solution is centrifuged, washed several times with ethanol, and then dried in an oven to obtain a ZnO core-shell structure precursor.

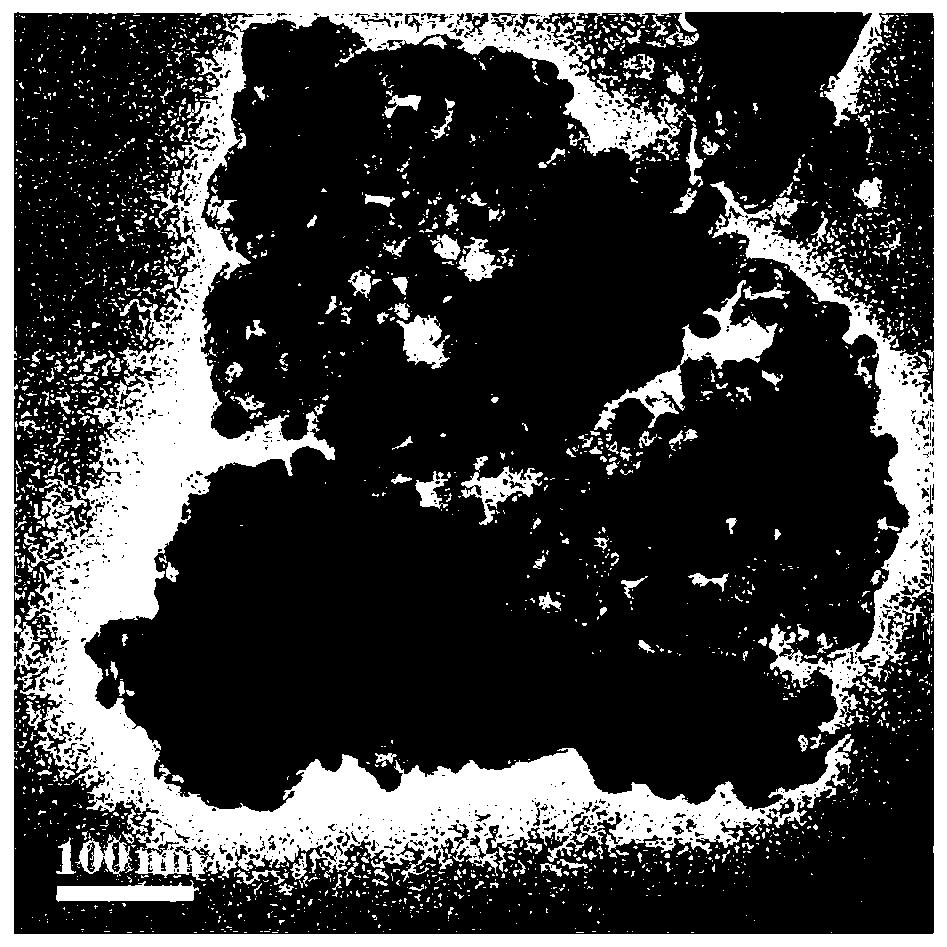

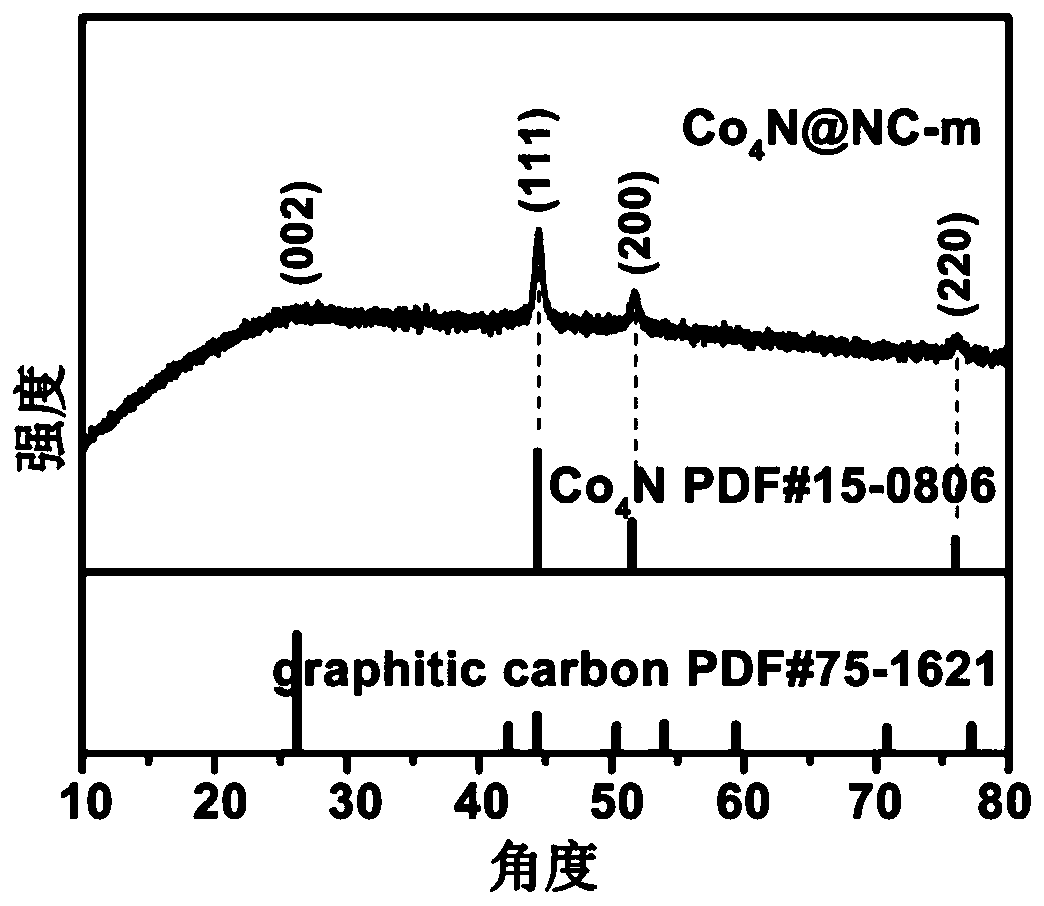

[0043] 2. Preparation of Co 4 N-supported nitrogen-doped carbon materials

[0044] 1) Weigh 0.04g of cobalt nitrate and add it to 10ml of aqueous solution in which 0.08g of ZnO core-shell structure precursor is dissolved, then slowly add 5ml of hydrazine hydrate to the solution, and stir and react at room temperature for 60min;

[0045] 2) Centrifuge the reacted solution and wash it several times with ethanol;

[0046] 3) adding 0.50 g of melamine to the product obtained above fo...

Embodiment 2

[0052] 1. Preparation of ZnO core-shell structure precursor

[0053] 1) Dissolve 0.20g P123, 0.15g Tris and 0.08g ZnO nanospheres in water, stir and mix evenly to obtain a mixed aqueous solution;

[0054] 2) 0.20 g of dopamine was dissolved in deionized water, added to the above solution, and stirred and reacted at room temperature for 3 hours;

[0055] 3) The reacted solution is centrifuged, washed several times with ethanol, and then dried in an oven to obtain a ZnO core-shell structure precursor.

[0056] 2. Preparation of Co 4 N-supported nitrogen-doped carbon materials

[0057] 1) Weigh 0.50g of cobalt nitrate and add it to 10ml of aqueous solution in which 2.00g of ZnO core-shell structure precursor is dissolved, then slowly add 2ml of hydrazine hydrate to the solution, and stir and react at room temperature for 40min;

[0058] 2) Centrifuge the reacted solution and wash it several times with ethanol;

[0059] 3) adding 0.30 g of melamine to the product obtained abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com