Nano-hydroxyapatite dry method modified nano black carbon heavy metal absorbent as well as preparation method and application thereof

A technology of nano-hydroxyapatite and hydroxyapatite, which is applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of poor adsorption passivation effect and poor adsorption performance, and achieve reaction High speed, high selectivity, and the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of nano-hydroxyapatite dry-modified nano-carbon heavy metal adsorbent

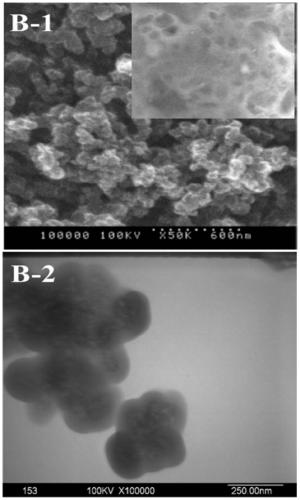

[0058] Weigh a certain amount of nano-black carbon and HAP in proportion to the mortar, and grind them thoroughly for 15 minutes. The parameters were optimized through single factor experiments, and the mass ratio of HAP:MBC was set to 1:10, and the obtained product was resistant to heavy metal Cu 2+ and Cd 2+ The adsorption capacity is used as the standard to determine the optimal preparation parameters. After mixing evenly, grind at normal temperature for 15 minutes to finally obtain nano-hydroxyapatite modified nano-black carbon adsorbent before dry method modification, and nano-black carbon is a nano-black carbon solid modified by potassium permanganate nitrate first.

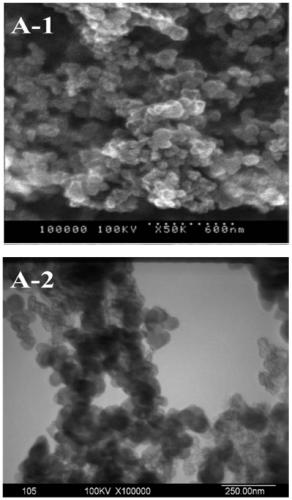

[0059] Depend on figure 1 Shown, A-1 SEM characterization before nano black carbon HAP modification, B-1 SEM characterization after nano black carbon HAP modification, A-2 TEM characterization before nano black car...

Embodiment 2

[0061] The difference from Example 1 is that the mass ratio of HAP to MBC is 1:5.

Embodiment 3

[0063] The difference from Example 1 is that the mass ratio of HAP to MBC is 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com