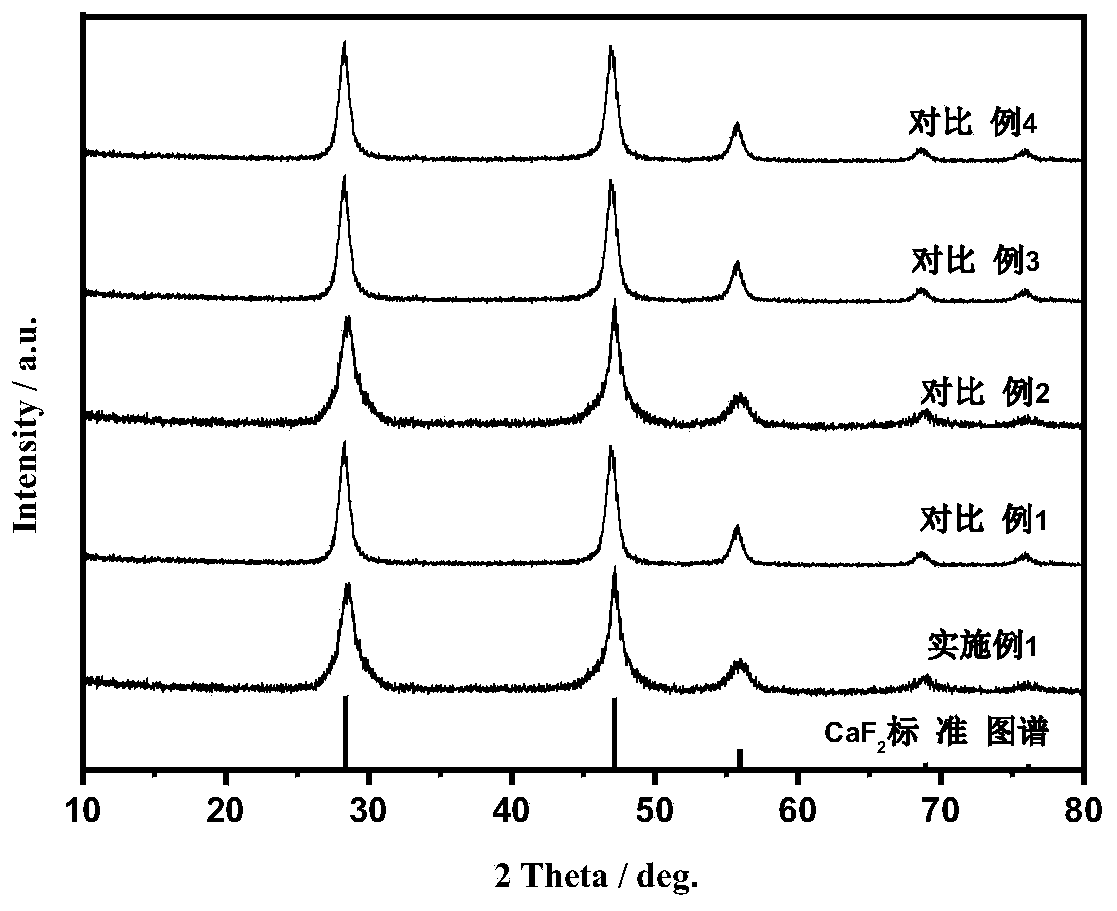

CaF2 material for absorbing trace water in HF gas and preparation method thereof

A technology of trace moisture and gas, applied in the field of CaF2 material and its preparation, can solve the problem of water absorption without thermal stability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

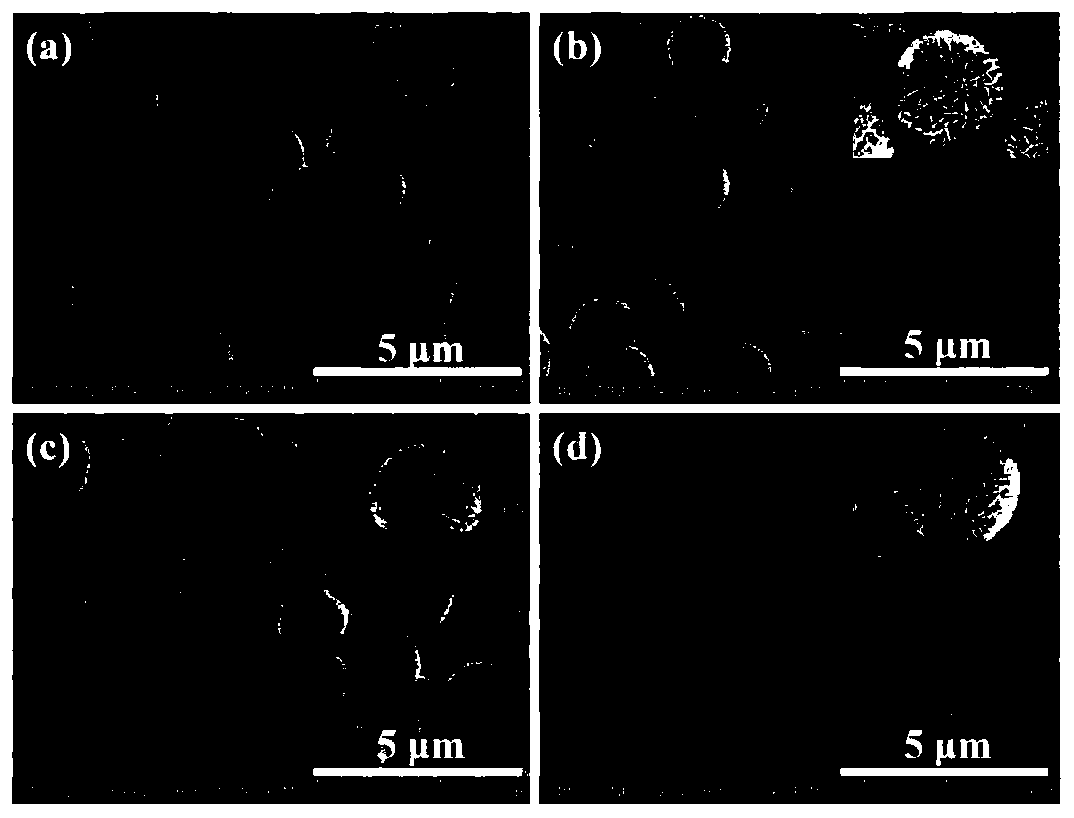

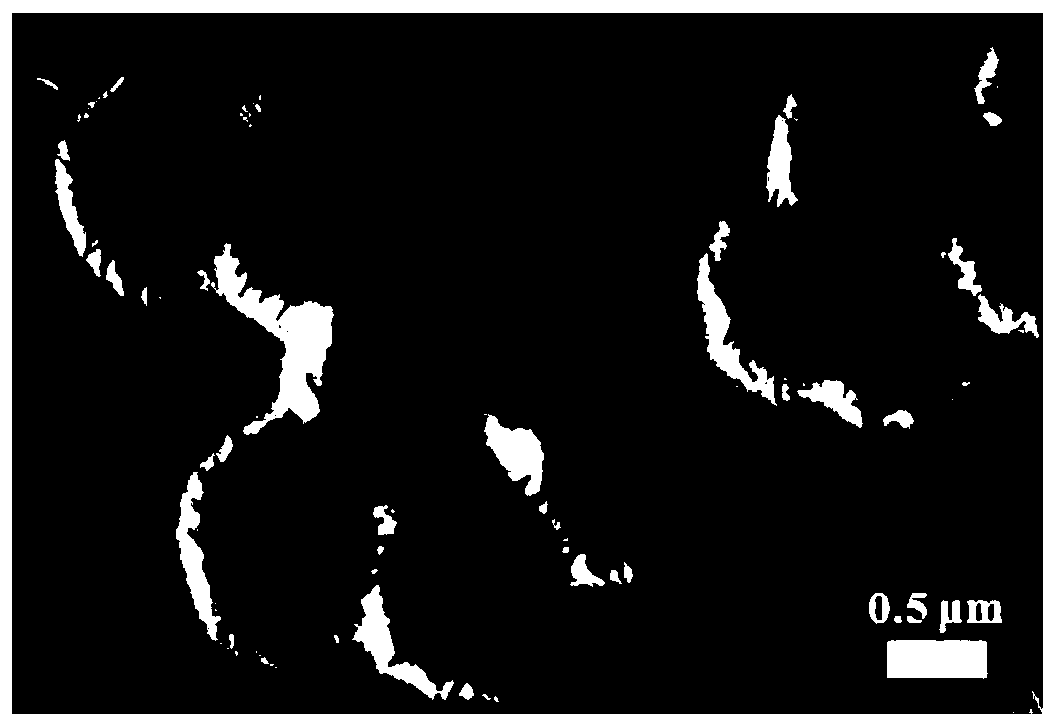

Embodiment 1

[0035] Take Na 3 C 6 h 5 o 7 2H 2 O is a complexing agent, Ca(CH 3 COO) 2 For calcium source, NaBF 4 is the source of fluorine, according to the molar ratio of each material is Ca(CH 3 COO) 2 :Na 3 C 6 h 5 o 7 :NaBF 4 :H 2 O=1:5:2:1676.6, with 1mmol Ca(CH 3 COO) 2 Dissolve in 30mL distilled water, after stirring and dissolving, add 5mmol Na 3 C 6 h 5 o 7 2H 2 O, magnetically stirred for 10min to form a mixed solution A, and then added 2mmol NaBF in the mixed solution A 4 At the same time, add ammonia water dropwise to adjust the pH value of the solution to 10; magnetically stir for 60 minutes to obtain the mixed solution B, transfer the mixed solution B to a polytetrafluoroethylene-lined hydrothermal stainless steel reactor, and place it in an oven with a temperature setting of 433K Medium crystallization for 1 h; cooled to room temperature, alternately centrifuged and washed with distilled water and absolute ethanol, repeated 3 times, and finally the obta...

Embodiment 2

[0043] Take by weighing the nano flower shape CaF that embodiment 1 makes 2 0.5 g of the sample is packed into Hastelloy (Inconel) sample tubes whose length, outer diameter, and inner diameter are 10 cm, 0.635 cm, and 0.465 cm, respectively. High purity N 2 (purity>7N), at N 2 The flow rate is 20ml(STP)min -1 and CaF at a temperature of 573K 2 The samples were pretreated for 10 h. After the pretreatment, when the temperature of the sample tube drops to 298K, the water content is 10ppm, and the total flow rate is 8ml (STP)min -1 HF gas through CaF 2 Adsorption bed, the total experimental pressure is 105kPa, and UnisearchRB110-MPCO-H 2 The O moisture meter detects the moisture content in the HF gas stream after passing through the adsorption bed.

[0044] The results show that when the water content is 10ppm and the total flow rate is 8ml(STP)min -1 HF gas through CaF 2 After the adsorption bed layer, its moisture content is reduced to 100ppb and below, when HF gas cont...

Embodiment 3

[0046] First, according to the same steps as in Example 2, the water content is 10ppm, and the total flow rate is 8ml (STP)min -1 HF gas through CaF 2 adsorption bed. When moisture is in CaF 2 After the adsorption bed is saturated, switch the HF feed to high-purity N 2 (purity>7N), at N 2 The flow rate is 20ml(STP)min -1 and CaF at a temperature of 473K 2 The adsorbent is pretreated for 3 hours to realize the regeneration of the adsorbent. After the pretreatment, when the temperature of the sample tube drops to 298K, the water content is 10ppm, and the total flow rate is 8ml (STP)min. -1 HF gas through CaF 2 Adsorption bed, the total pressure of the experiment is 105kPa, while using Unisearch RB110-MPCO-H 2 The O moisture meter detects the moisture content in the HF gas stream after passing through the adsorption bed.

[0047] The results show that when the water content is 10ppm and the total flow rate is 8ml(STP)min -1 HF gas passes through regenerated CaF 2 Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com