Antifouling compositions for petroleum process streams

A petroleum process and composition technology, which can be used in drilling compositions, petroleum industry, processing hydrocarbon oil, etc., and can solve problems such as solubility problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

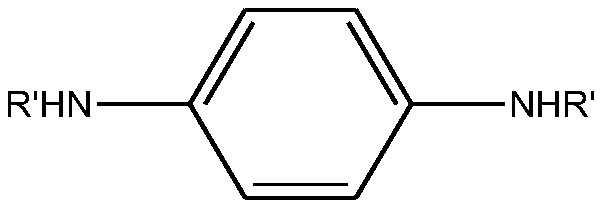

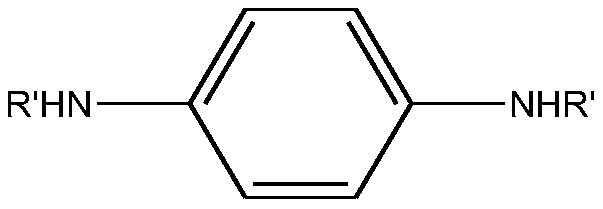

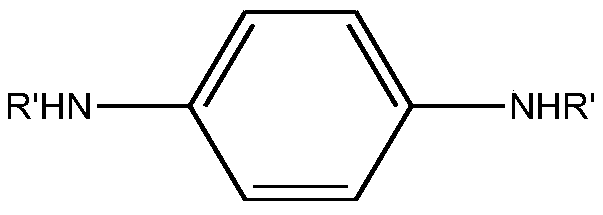

Image

Examples

example 1

[0081] According to the procedure outlined in Comer et al., US Patent No. 5,214,224, polyalkenylsuccinic acid, which is a copolymer of C24-C28 alpha-olefins and maleic anhydride (CAS No. 68459-79-0), was obtained. 50 g of polymer (obtained as solid at 100% active polymer) was then dispersed in 100 g of HAN (heavy aromatic naphtha) and the dispersion was heated to 60-65°C with constant stirring. Then 20 g of oleylamine (20 g) was slowly added to the mixture over 30 minutes. The temperature of the reaction mixture was observed to rise to about 80°C. The mixture was stirred for an additional 2 hours while maintaining the temperature at 60-65°C. Anhydride peaks (1780 and 1711cm -1 ) disappearance and amide peak (1679cm -1 ) appears.

[0082] When it was determined that the reaction was complete, another 100 g of HAN was added to the mixture, and the mixture was stirred for another 30 minutes. The mixture was then cooled to ambient temperature and filtered to remove traces of ...

example 2-7

[0084] The inflection point and induction period of liquid petroleum products in the presence of the polymer of Example 1 were determined using ASTM-D525. Treated or untreated liquid petroleum samples were oxidized in an oxygen-filled pressure vessel at 690 kPa to 705 kPa, at 15°C to 25°C, and then heated to a temperature of 98°C to 102°C. The pressure in the vessel is monitored over time. The inflection point is defined in ASTM-D525 as the point in the pressure-time curve at which the pressure drop is exactly 14 kPa in the 15 minutes before it, and the drop is not less than 14 kPa in the next 15 minutes. The induction period in ASTM-D525 is defined as the time elapsed between placing the pressure vessel in the temperature bath and the point of inflection. Using this test, induction period and inflection point results are measured to provide an indication of the tendency of liquid petroleum products to form synthetic fouling during storage. A shorter induction period indicat...

example 8

[0091] The coker naphtha feed was tested for induction period according to ASTM-D525 using the procedures and additive compositions of Examples 2-7. No additive resulted in an induction period of 1.96 hours; 500 ppm Inhibitor C provided an induction period of 6.35 hours; and 1666 ppm of the antiscalant composition (corresponding to 500 ppm Inhibitor C) provided an induction period of greater than 8.0 hours: i.e., tested at 8.0 hours Discontinue without reaching the end of the induction period.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com