Backlight unit of uniformly light-emitting module lamp box

A technology of backlight unit and uniform light emission, which is applied in the direction of optical components, optics, and illuminated marks, etc., can solve the problems such as the inability to realize shadowless splicing, and achieve the effect of simple structure, meeting splicing requirements, and outdoor applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the backlight unit of the uniformly luminous modular light box of the present invention.

[0028] The front side and the rear side described in this embodiment are based on the directions shown in the description of the drawings.

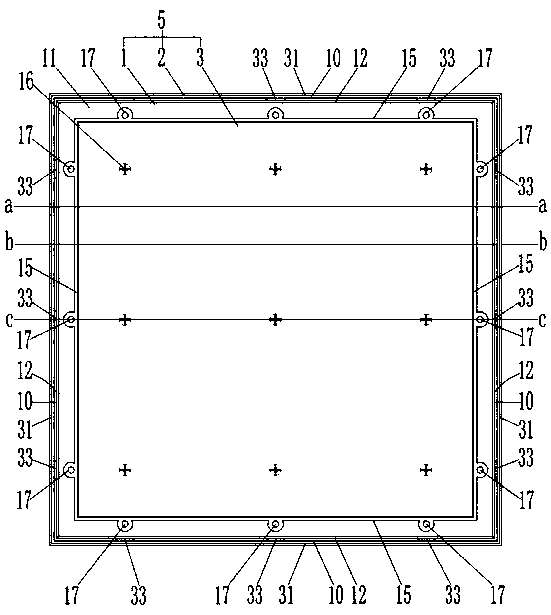

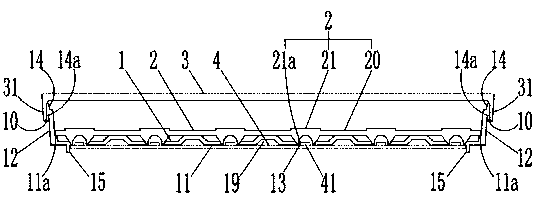

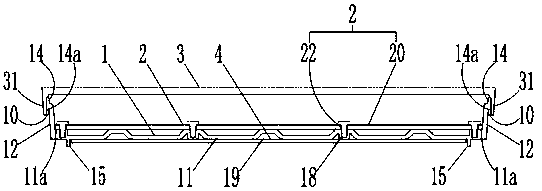

[0029] Embodiments of the backlight unit of the uniformly luminous modular light box of the present invention, such as Figure 1 to Figure 8As shown, the backlight unit 5 is composed of a basin-shaped box body 1 installed concurrently with a light source module, a lens module 2 , a panel 3 and a light source module 3 . Above-mentioned basin-shaped box body 1 comprises box body bottom plate 11, the box wall 12 that protrudes forward around this box body bottom plate 11, the lamp hole 13 on the bottom plate that is positioned at the box body bottom plate 11 and is evenly distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com