Geothermal development system and construction method thereof

A technology for developing systems and geothermal energy, applied in geothermal energy power generation, geothermal energy, geothermal collectors, etc., can solve problems such as bankruptcy and lack of resources, increase heat exchange area, avoid pipeline blockage, and reduce system energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

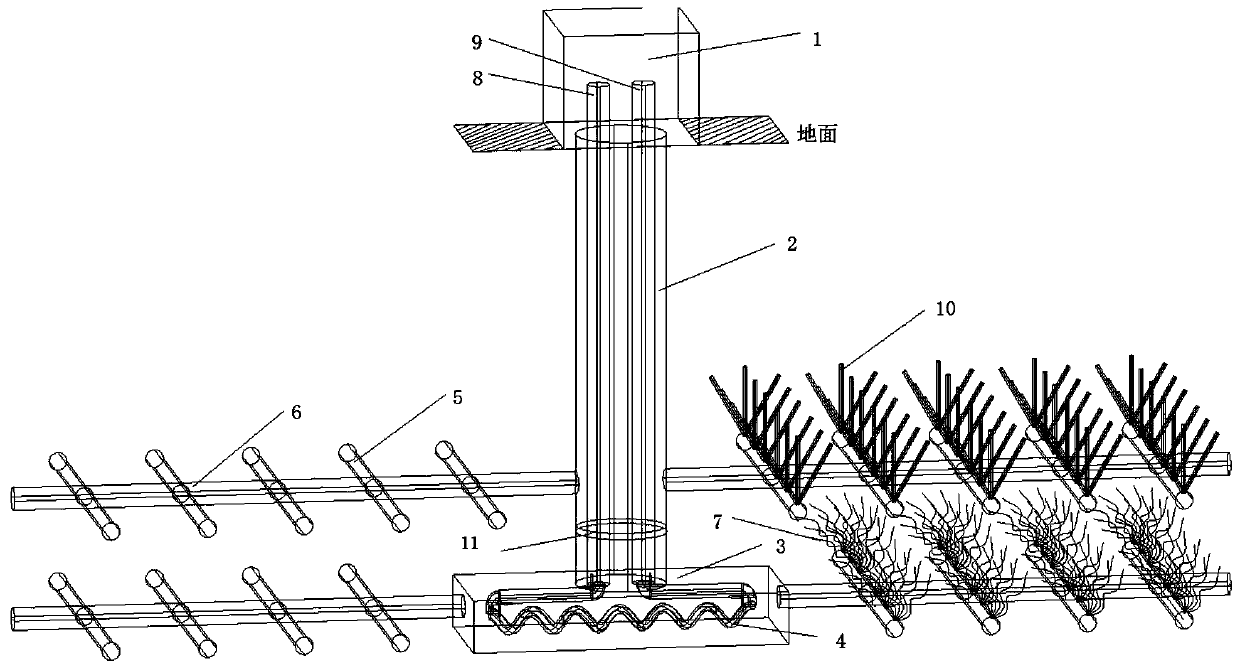

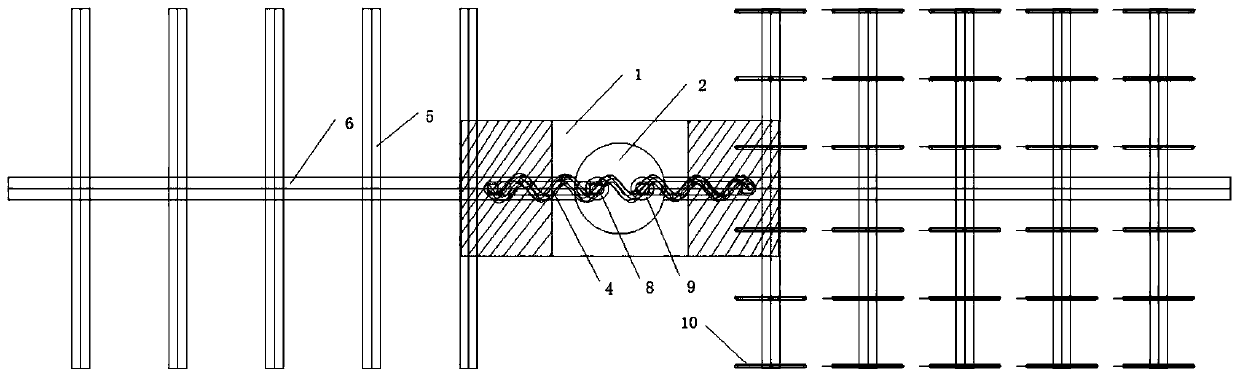

[0042] Such as figure 1 As shown, a thermal mine development system provided in this embodiment includes a large-diameter vertical shaft 2, which can be constructed through vertical shaft construction technology, or a blind shaft can be built by using the existing shaft in mining. The diameter of the large-diameter shaft 2 is 3-10m, and its vertical depth is 3000-10000m, until the underground is opened up to form an underground high-temperature and high-pressure heat exchange pool 3, which has a diameter of 30-50m and a height of about 1m. It is related to the number of layers provided in the heat exchange guide channel 4 . Both the injection pipeline 8 and the collection pipeline 9 are arranged along the inner wall of the large-diameter shaft 2, and form a heat exchange and flow guide channel 4 in the underground high-temperature and high-pressure heat exchange pool 3. The injection pipeline 8 and the collection pipeline 9 are made of high-temperature, high-pressure and heat-...

Embodiment 2

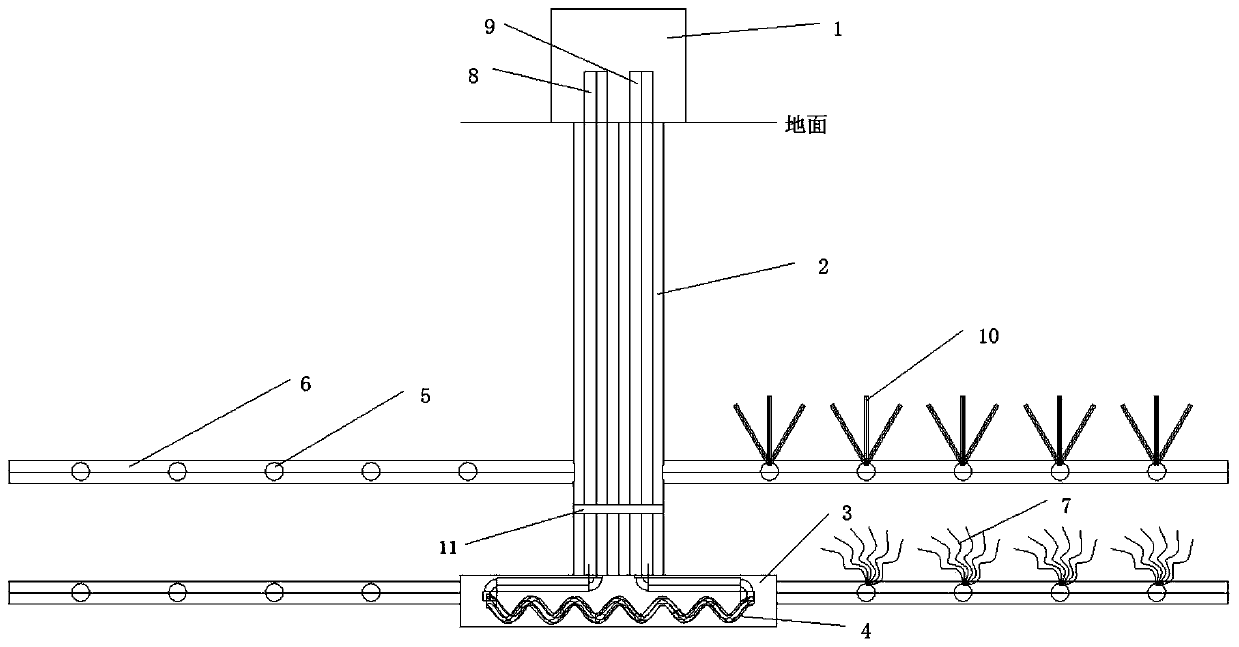

[0058] Such as figure 2 As shown, a thermal mine development system in this embodiment includes a large-diameter vertical shaft 2, and the shaft can be constructed through shaft construction technology, or a blind shaft can be constructed by using an existing shaft in mining. The diameter of the large-diameter shaft 2 is 3-10m, and its vertical depth is 3000-10000m. The underground high temperature and high pressure heat exchange pool 3 is formed by underground development. The diameter of the underground high temperature and high pressure heat exchange pool 3 is 30-50m, and the height is about 1m, which is related to the number of layers of the heat exchange and flow guide channel 4. Both the injection pipeline 8 and the collection pipeline 9 are arranged along the inner wall of the large-diameter shaft 2, and the injection pipeline 8 and the collection pipeline 9 are made of materials resistant to high temperature, high pressure and heat insulation.

[0059] Boreholes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com