Organic solid fuel pyrolysis, gasification and incineration integrated device and treatment method

A technology of pyrolysis and gasification of organic solids, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve problems such as low thermal efficiency and excessive exhaust pollutants, and achieve high treatment efficiency, efficient utilization, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

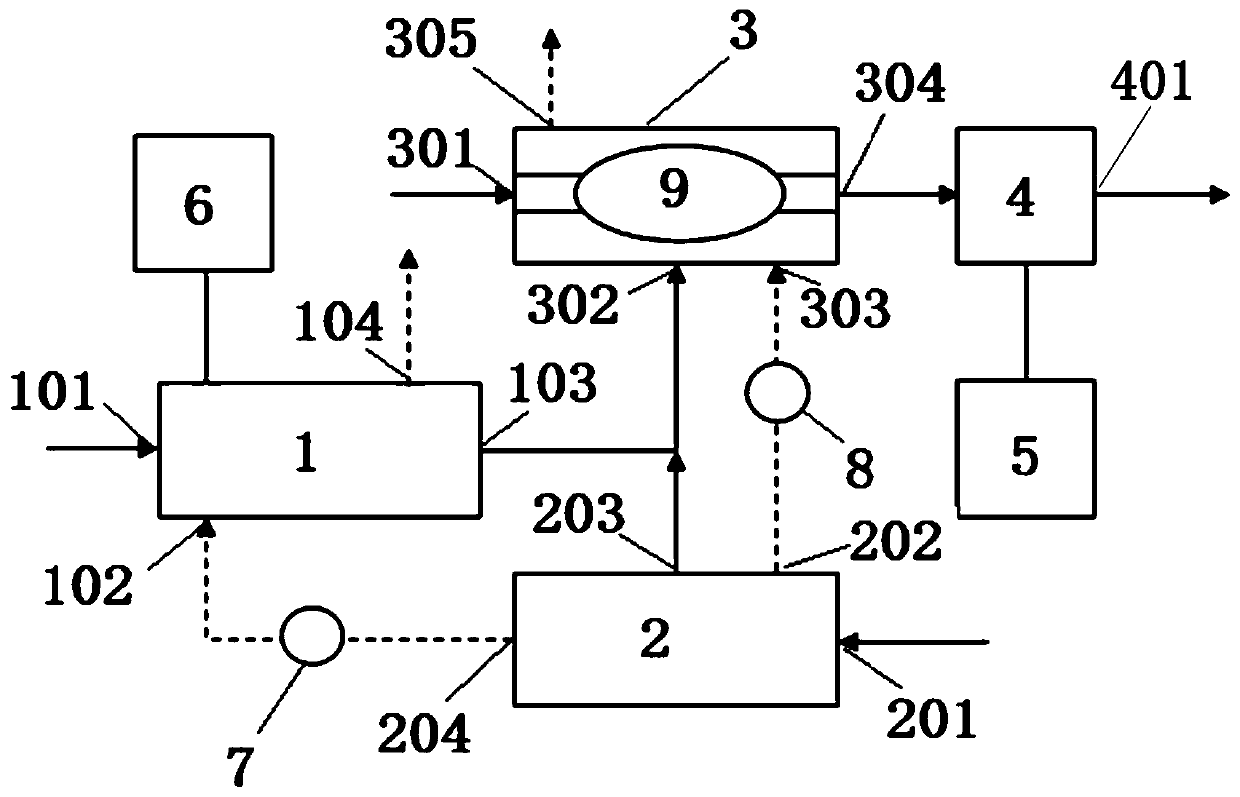

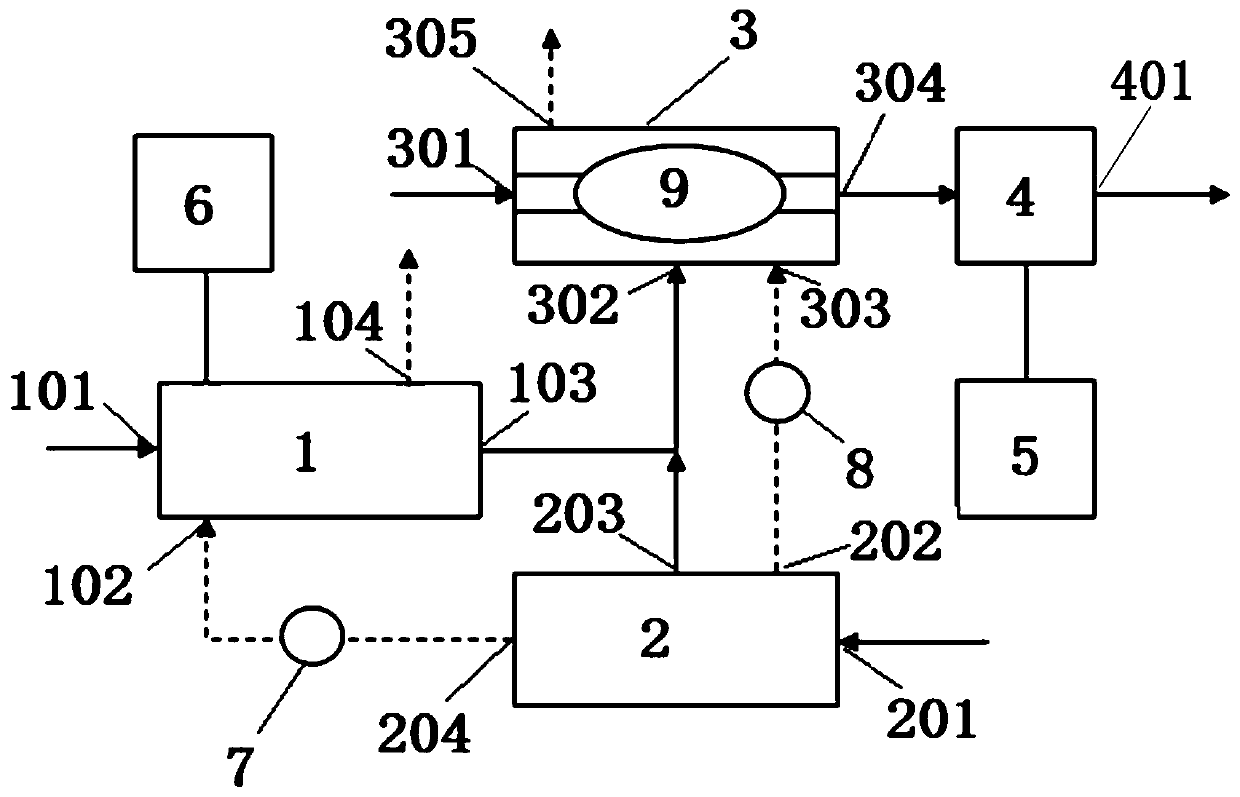

[0040] The organic solid fuel continuous feeding pyrolysis, gasification and incineration integrated device of the present invention can be used for pyrolysis, gasification and coke incineration of organic solid fuel. The incinerator 2 can choose a fixed bed reactor or a rotary bed reactor equipped with a screw conveyor. Air, oxygen, water vapor or their mixture enters the incineration device 2 through the air inlet as a combustion aid to participate in the reaction. When the combustion aid is air or oxygen, the incineration reaction of coke occurs in the incineration device 2, and the flue gas from the incineration device 2 passes through the pyrolysis gasification device 1 and the catalytic reforming device 3 respectively through the flue gas pipeline connected to the gas outlet. bed, heating the solid material in the bed. According to the different preset temperatures of the pyrolysis gasification unit 1 and the catalytic reformer 3 , the regulating valve respectively adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com