Method for longwall recovering of room and pillar goaf remaining coal pillars

A technology of legacy coal pillars and room pillars, which is applied in ground mining, mining equipment, earth cube drilling, etc., can solve problems such as hidden dangers in production and life, lack of recovery methods, instability of coal pillars, etc., and achieve simple and mature mining methods, Good safety and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

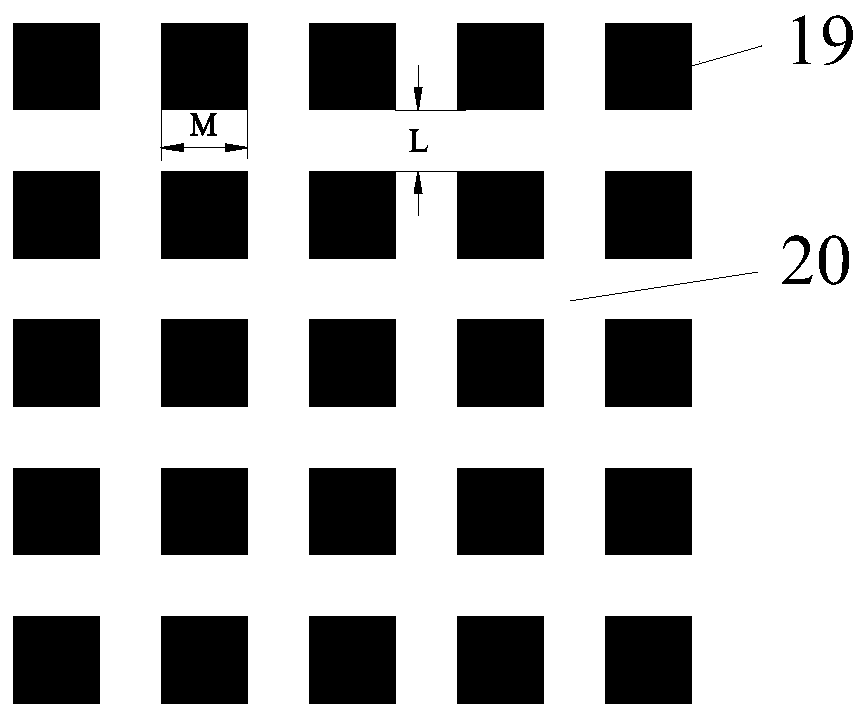

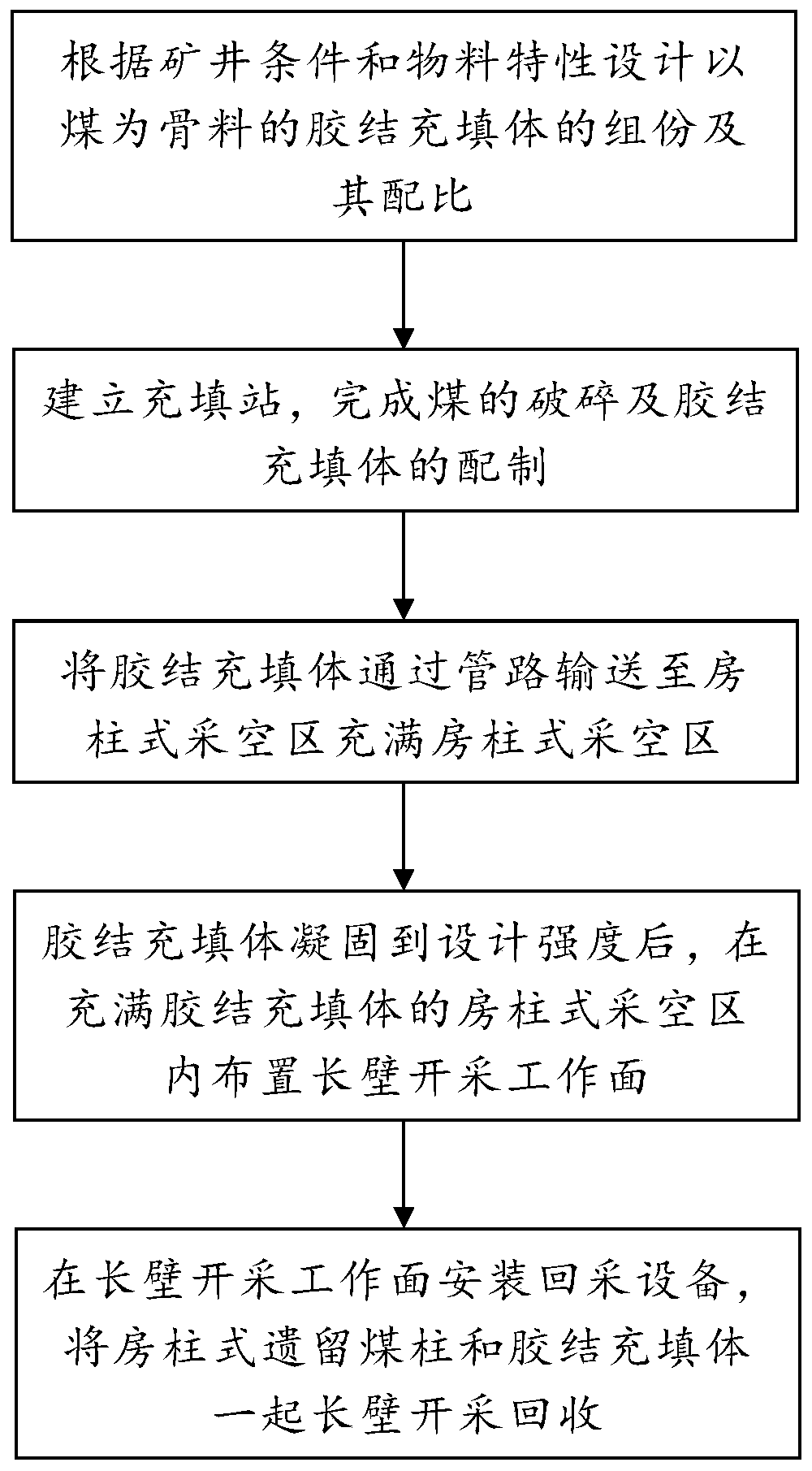

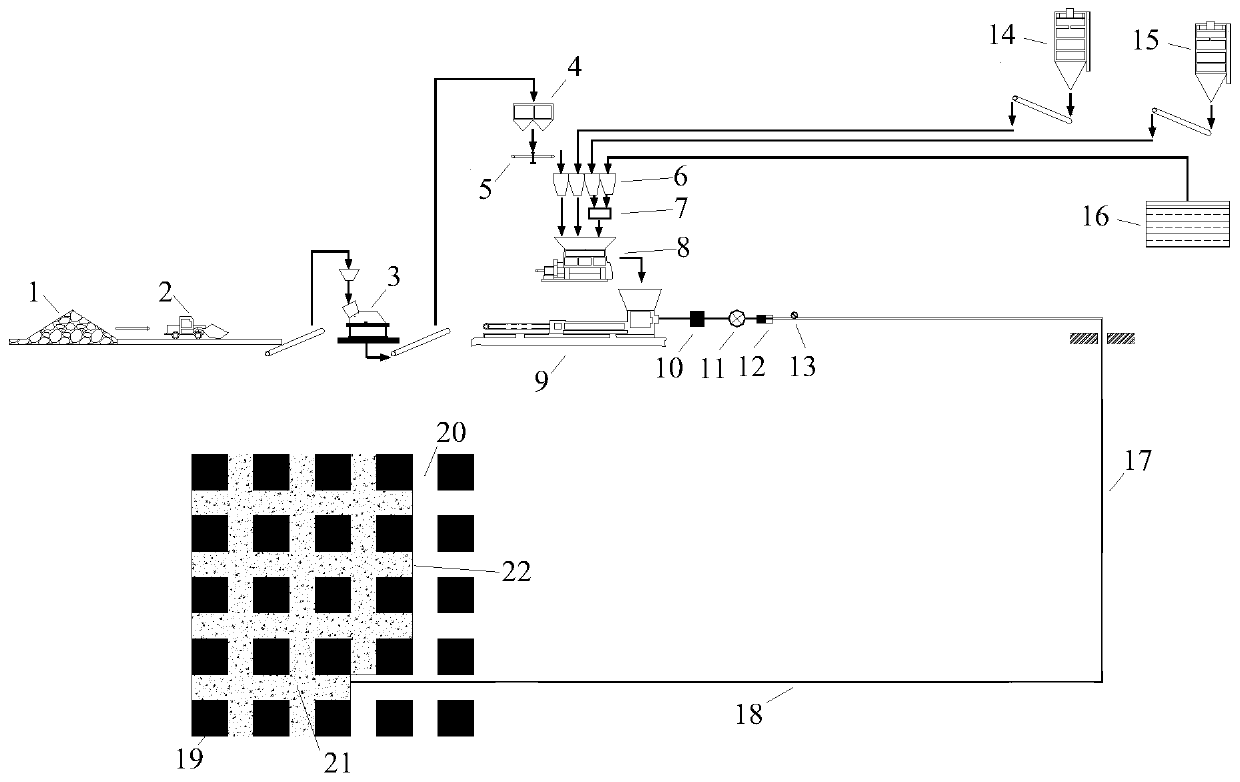

[0036] A mine has a room-and-pillar goaf, a near-horizontal coal seam, buried depth H = 410m, mining thickness M = 3m, mining width L = 6m, and leftover coal pillar width D = 6m. The ratio of the coal aggregate filling body used per cubic meter is: coal 1394Kg; fly ash 66Kg; cementing material 40Kg; admixture accelerator 5.5Kg and water reducer 2.5Kg; mine water 590Kg. The slurry mass concentration is 71.9%, the slump is 23cm, and the 28d uniaxial compressive strength is 1.1MPa.

[0037] The coal is coal lumps and coal particles with a particle size of less than 24mm after secondary crushing. 12% for 13.5mm-17.5mm, 23% for 9mm-13.5mm, 29% for 5mm-9mm, 16% for 4.3mm-5mm, 0.1 mm-4.3mm accounted for 8%, particle size of 0.075mm-0.1mm accounted for 3%.

[0038] The fly ash is the secondary fly ash of the power plant, the cementing material is ordinary portland cement of grade 32.5, and the quick-setting agent is composed of alumina clinker, sodium carbonate and quicklime accordi...

Embodiment 2

[0046] In the room-and-pillar goaf of a mine, the inclination angle of the coal seam is α=5°, the buried depth is H=570m, the mining thickness is M=4.5m, the mining width is L=5m, and the width of the remaining coal pillar is D=8m. The proportion of the coal aggregate filling body used is: coal 1450Kg; fly ash 66Kg; cementing material 42Kg; admixture accelerator 6.1Kg and water reducer 1.9Kg; mine water 574Kg. The slurry mass concentration is 72.4%, the slump is 23.5cm, and the 28d uniaxial compressive strength is 1.5MPa.

[0047] The coal is coal lumps and coal particles with a particle size of less than 20mm after secondary crushing, the coal type is anthracite, 7% of the particle size is 17.5mm-20mm, and 15% of the particle size is 13.5mm-17.5mm. The particle size of 9mm-13.5mm accounts for 22%, the particle size of 5mm-9mm accounts for 27%, the particle size of 4.3mm-5mm accounts for 17%, the particle size of 0.1mm-4.3mm accounts for 8%. 0.075mm-0.1mm accounted for 4%.

...

Embodiment 3

[0056] In the room-and-pillar goaf of a mine, the coal seam dip angle is α=7°, the buried depth is H=634m, the mining thickness is M=5.8m, the mining width is L=4m, and the remaining coal pillar width is D=9m. The proportion of the coal aggregate filling body used is: coal 1503Kg; fly ash 70Kg; cementing material 35Kg; admixture accelerator 5.2Kg and water reducer 2.8Kg; mine water 612Kg. The slurry mass concentration is 72.5%, the slump is 22.5cm, and the 28d uniaxial compressive strength is 1.7MPa.

[0057] The coal is coal lumps and coal particles with a particle size of less than 22mm after secondary crushing. 11% with a diameter of 13.5mm-17.5mm, 24% with a particle size of 9mm-13.5mm, 31% with a particle size of 5mm-9mm, 11% with a particle size of 4.3mm-5mm, and 11% with a particle size of 0.1mm-4.3mm accounted for 8%, particle size 0.075mm-0.1mm accounted for 6%.

[0058] The fly ash is the third-grade fly ash of the power plant, the cementing material is carbide sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com