Barrier gate machine core device with efficient transmission and high adjustability

An adjustable and high-efficiency technology, applied in roads, roads, restricted traffic and other directions, can solve the problems of large jitter of the brake lever, high cost, and affecting the life of the motor, so as to improve the efficiency of force transmission, small movement gap and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

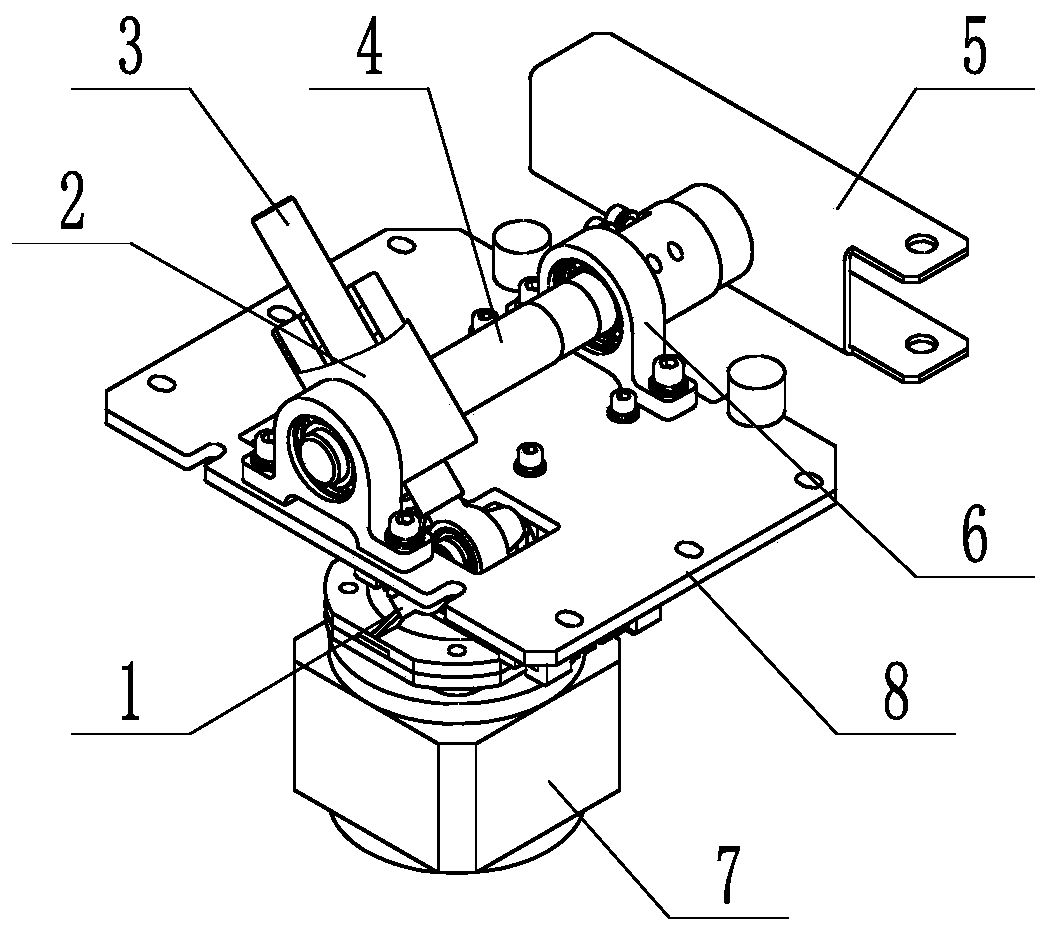

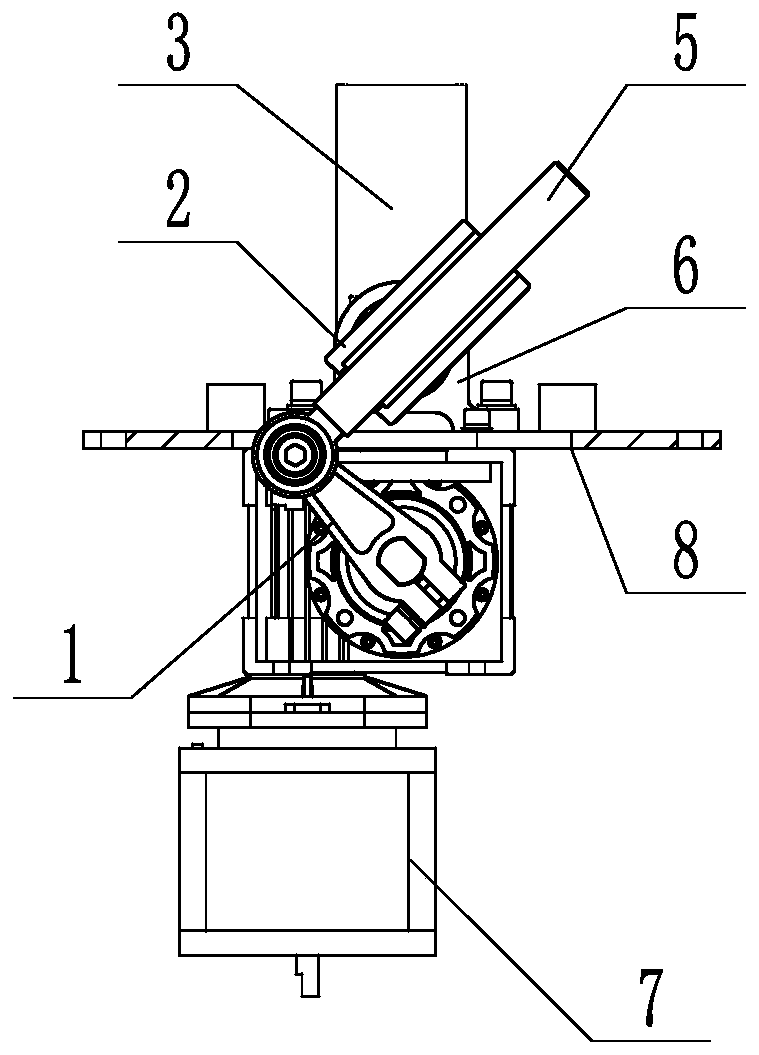

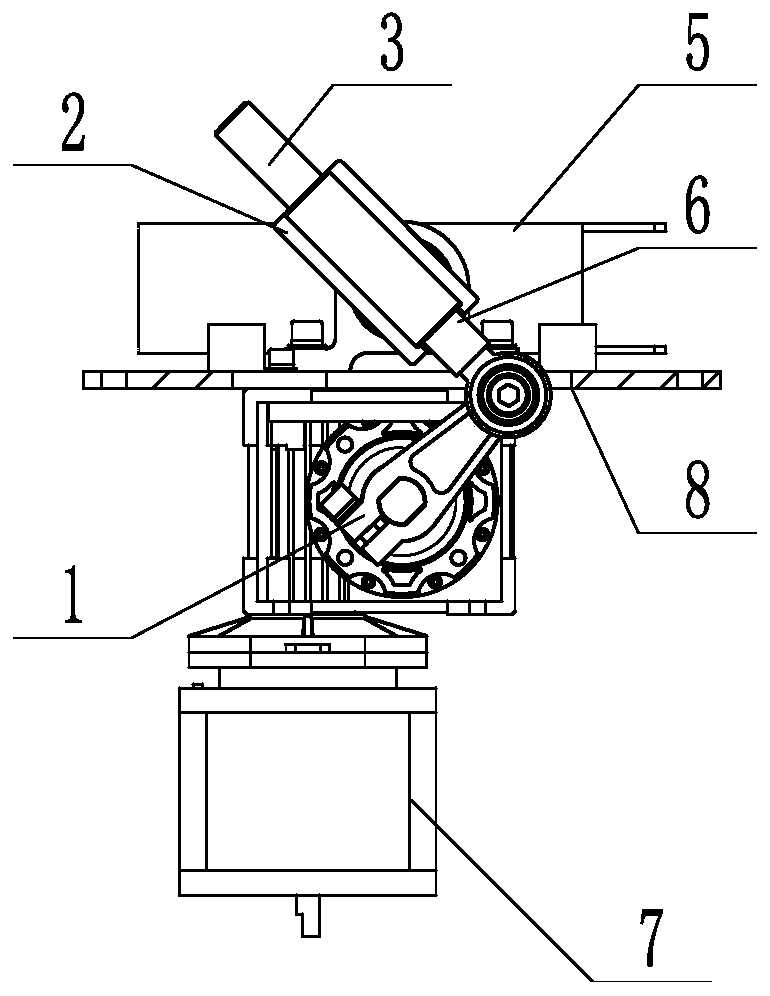

[0018] Such as figure 1 As shown, a barrier gate movement device with high transmission efficiency and high adjustability includes a motor crank 1, a guide rod 3, and a transmission spindle 4. The first end of the motor crank 1 is fixedly connected to the output shaft of the geared motor. The second end of the motor crank 1 is hinged to the guide rod 3, and the transmission main shaft 4 includes a first shaft portion and a second shaft portion on the same rotation center line, and a shaft is provided between the first shaft portion and the second shaft portion The slider support 2, the first shaft part and the second shaft part are installed on the frame 8 through the bearing housing 6 respectively, the guide rod 3 is slidingly connected with the slider support 3, the motor crank 1 rotates and Drive the guide rod 3 to swing, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com