Auxiliary nozzle of air-jet loom

A technology for auxiliary nozzles and air-jet looms, which is applied in the field of auxiliary nozzles and air-flow nozzles for air-jet looms. It can solve the problems of increased operating costs, slow air flow velocity, and excessive air volume, and achieves cost savings, fast outlet flow velocity, and low air consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

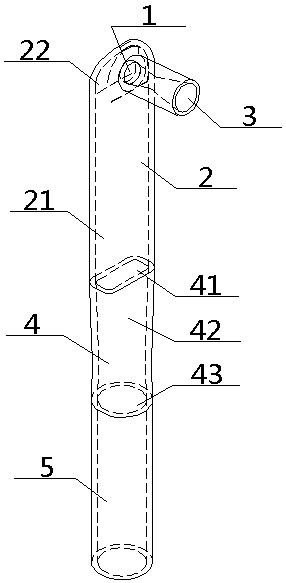

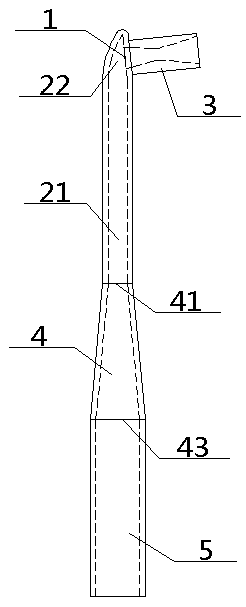

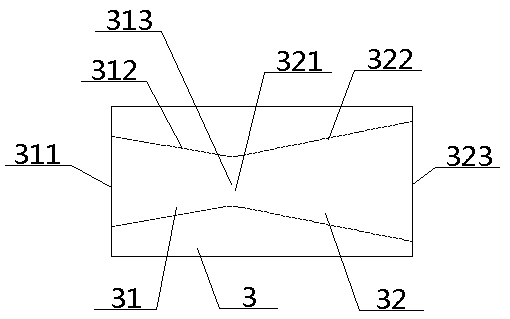

[0041] see Figure 1 to Figure 7 , an auxiliary nozzle for an air-jet loom, comprising a main air pipe 2 and an air outlet 1, the side of the main air pipe 2 near its top is provided with an inclined pipe wall 222, and the inclined pipe wall 222 is provided with an air outlet 1 , the air outlet 1 communicates with an external air source through the main air pipe 2; the auxiliary nozzle of the air-jet loom also includes an inclined nozzle 3, and the interior of the inclined nozzle 3 is provided with a converging cavity 31 and a gradually expanding cavity 32 , the inner end of the tapering chamber 31 communicates with the gas outlet 1, the outer end of the tapering chamber 31 coincides with the inner end of the expanding chamber 32, and the outer end of the tapering chamber 32 is level with the outer end of the inclined nozzle 3 Qi, the inner end of the inclined nozzle 3 is connected with the inclined pipe wall 222. Preferably, the cross-section of the tapered cavity 31 is an i...

Embodiment 2

[0043] Basic content is the same as embodiment 1, the difference is:

[0044] The main air pipe 2 includes a main lower air pipe 21 and a main upper pipe head 22. The main lower air pipe 21 is a hollow structure with openings at both ends, and the main upper pipe head 22 is a one-way opening structure with a downward opening. The pipe head 22 includes an arc-shaped outer wall 221, a pipe head side wall 223 and an inclined pipe wall 222. The top 224 is a closed structure, and the bottom of the arc-shaped outer wall 221, the side wall 223 of the pipe head 223 and the inclined pipe wall 222 together form a bottom opening 225 of the pipe head, which is connected to the top of the main lower air pipe 21. The inclined nozzle 3 communicates with the external air source after passing through the air outlet 1, the bottom opening 225 of the pipe head, and the main lower air pipe 21 in sequence.

Embodiment 3

[0046] Basic content is the same as embodiment 2, the difference is:

[0047] The bottom end of the main lower trachea 21 communicates with the external air source after passing through the middle trachea 4 and the bottom trachea 5 successively. Port 43, the top port 41 of the middle pipe is connected to the bottom of the main lower air pipe 21, the bottom port 43 of the middle pipe is connected to the top of the bottom air pipe 5, and the area of the top port 41 of the middle pipe is smaller than that of the bottom port 43 of the middle pipe area. The cross section of the main lower air pipe 21 is rectangular, the top opening 41 of the middle pipe is rectangular, the bottom opening 43 of the middle pipe is circular, and the cross section of the bottom air pipe 5 is circular. The wide side 411 of the cross section of the top opening 41 of the middle pipe is shorter than the diameter of the bottom opening 43 of the middle pipe, and the long side 412 of the cross section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com