Elastic composite fiber and manufacturing method thereof

A technology of elastic composite fibers and manufacturing methods, applied in fiber processing, conjugated synthetic polymer artificial filaments, melt spinning, etc., can solve the problems of general three-dimensional crimping, poor thermal stability, and lack of elasticity, etc., to achieve Good spinnability, bright colors, good fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for manufacturing elastic composite fibers, comprising the steps of:

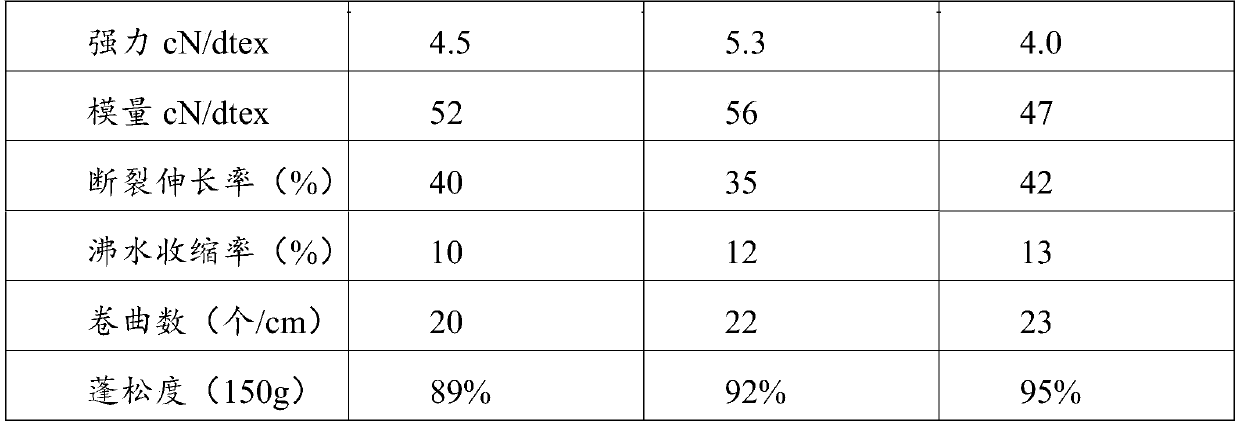

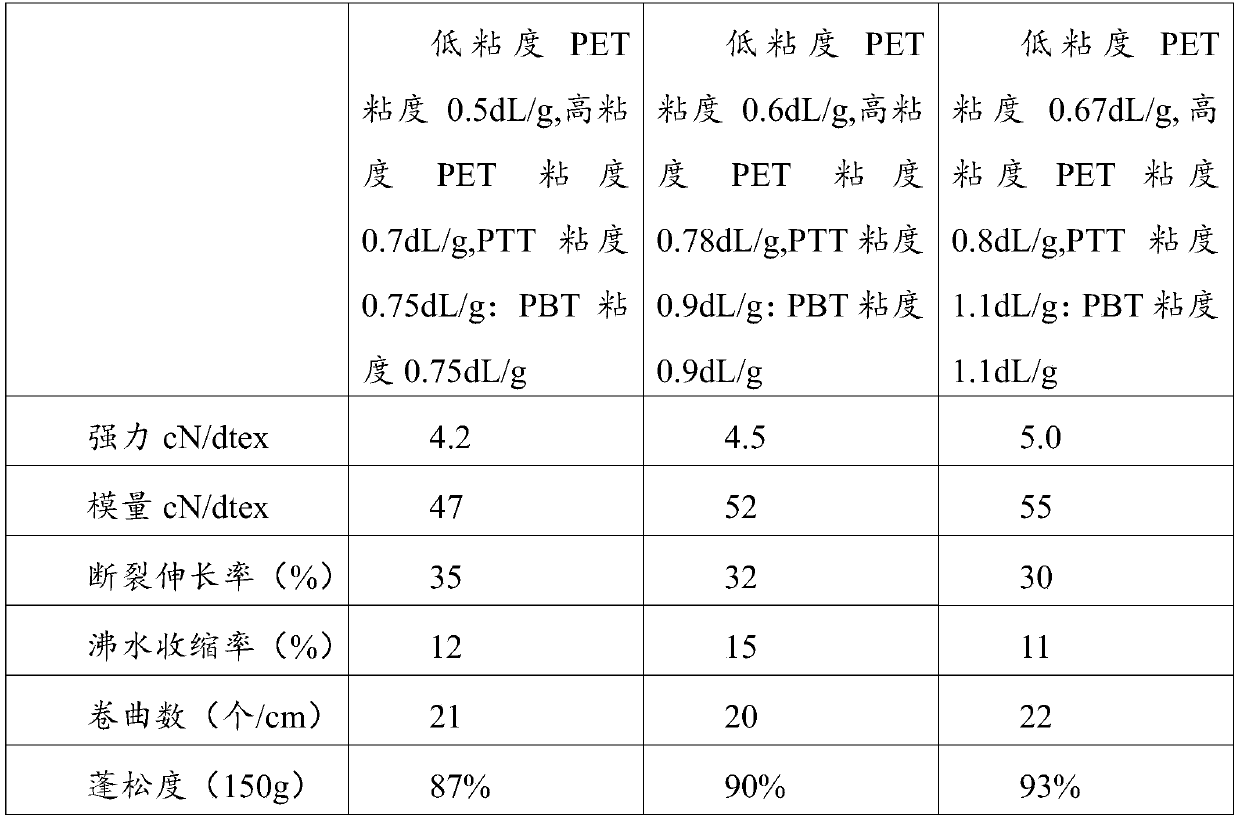

[0026] Step A: Dry low-viscosity PET, high-viscosity PET, PTT, and PBT until the water content is less than 15ppm. The viscosity of low-viscosity PET is 0.42dL / g, the viscosity of high-viscosity PET is 0.83dL / g, and the viscosity of PTT is 0.92dL / g, PBT viscosity is 0.92dL / g;

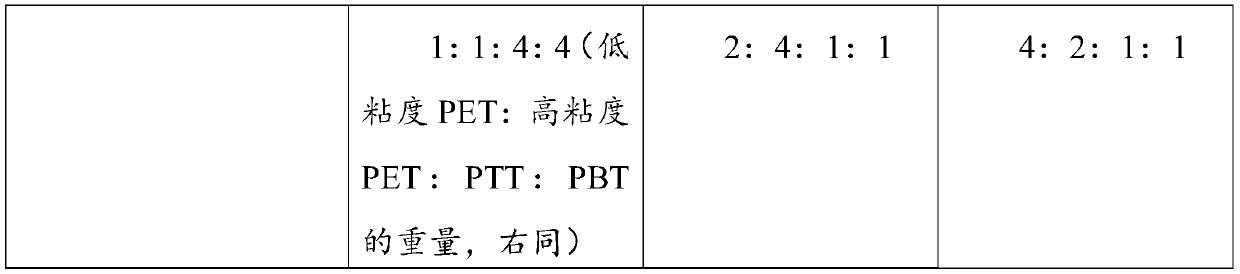

[0027] Step B: Put low-viscosity PET, high-viscosity PET, PTT, and PBT into the screw extruder for melt extrusion, and meter them into the composite spinning assembly through a metering pump. The composite spinning assembly is a large-capacity double The spinning member of the channel composite spinning device, the weight percentage of low viscosity PET accounts for 20% of the total material, the weight percentage of high viscosity PET accounts for 20% of the total material, the weight percentage of PTT accounts for 30% of the total material, and the weight of PBT The percentage accounts for 30% of the total material...

Embodiment 2

[0032] Step A: Dry low-viscosity PET, high-viscosity PET, PTT, and PBT until the water content is less than 15ppm. The viscosity of low-viscosity PET is 0.42dL / g, the viscosity of high-viscosity PET is 0.83dL / g, and the viscosity of PTT is 0.92dL / g, PBT viscosity is 0.92dL / g;

[0033] Step B: Put low-viscosity PET, high-viscosity PET, PTT, and PBT into the screw extruder for melt extrusion, and meter them into the composite spinning assembly through a metering pump. The composite spinning assembly is a large-capacity double The spinning member of the channel composite spinning device, the weight percentage of low viscosity PET accounts for 20% of the total material, the weight percentage of high viscosity PET accounts for 20% of the total material, the weight percentage of PTT accounts for 30% of the total material, and the weight of PBT The percentage accounts for 30% of the total material; the melt from the composite spinning assembly is introduced into the spinneret to be s...

Embodiment 3

[0038] A method for manufacturing elastic composite fibers, comprising the steps of:

[0039] Step A: Dry low-viscosity PET, high-viscosity PET, PTT, and PBT until the water content is lower than 15ppm. The viscosity of low-viscosity PET is 0.55dL / g, the viscosity of high-viscosity PET is 0.75dL / g, and the viscosity of PTT is 0.95dL / g, PBT viscosity is 0.95dL / g;

[0040] Step B: Put low-viscosity PET, high-viscosity PET, PTT, and PBT into the screw extruder for melt extrusion, and meter them into the composite spinning assembly through a metering pump. The composite spinning assembly is a large-capacity double The spinning member of the channel composite spinning device, the weight percentage of low viscosity PET accounts for 20% of the total material, the weight percentage of high viscosity PET accounts for 20% of the total material, the weight percentage of PTT accounts for 30% of the total material, and the weight of PBT The percentage accounts for 30% of the total materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com