Cyanide-free alkaline copper electroplating solution and electroplating process

A cyanide-free alkaline copper plating and electroplating process technology, applied in the field of electroplating, can solve the problems of high electron cloud density, slow crystal nucleus generation, limited dispersion ability, etc., and achieves good brightness and flatness, simple wastewater treatment, and dispersion ability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The synthetic method of N'-aminoethyl-benzoylthiourea, reaction formula is as follows:

[0051]

[0052] Add 2 mole parts of ethylenediamine into the reaction kettle, and gradually add 1 mole part of benzoyl isocyanate under rapid stirring to keep the heat dissipation well, so that the temperature of the reaction solution is between 8.5 and 40°C (this implementation example maintained at room temperature (25°C). After all the addition of benzoyl isocyanate is completed, the temperature of the reaction solution is slowly raised to 60-80°C, vacuumized, and the unreacted ethylenediamine is distilled off, and the distilled gas is condensed and recovered with -10°C ice-salt water until Until there is no distillate, the remaining substance in the reactor is mainly N'-aminoethyl-benzoylthiourea. This embodiment measures the concentration of N'-aminoethyl-benzoylthiourea in the product by complexometric titration, and after measuring, the content of N'-aminoethyl-benzoylthi...

Embodiment 2

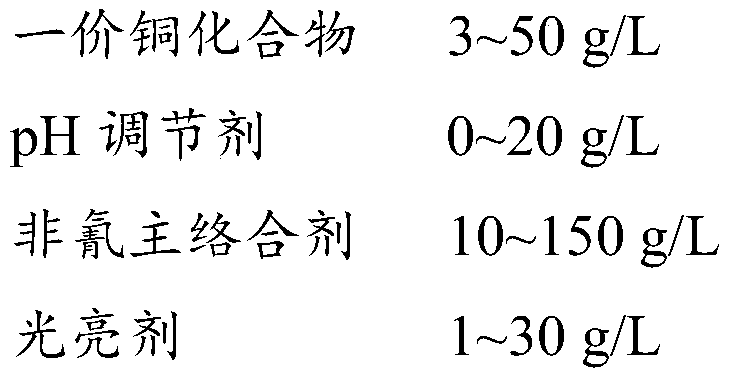

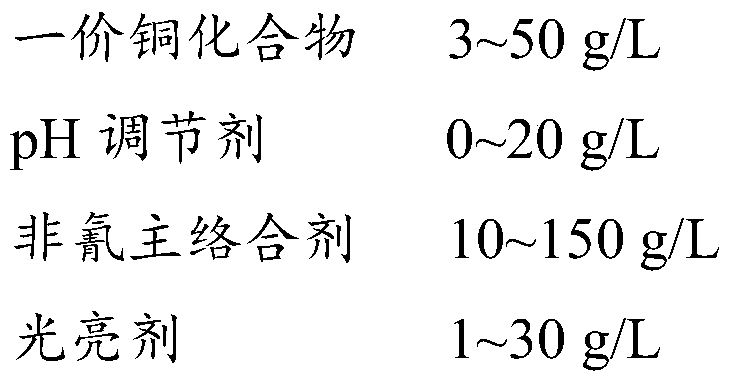

[0054] A kind of cyanide-free alkaline copper plating electroplating solution, it is made of following components:

[0055] The volume of the plating tank is calculated in 1L,

[0056]

[0057]

[0058] The solvent is deionized water.

[0059] The N'-aminoethyl-benzoylthiourea that present embodiment adopts is synthesized by the method for embodiment 1.

[0060] Prepare 1L cyanide-free alkaline copper plating electroplating solution according to the above scheme, and carry out electroplating and performance testing on it. The experimental conditions are: temperature is 45°C, cathode current density is 2A / dm 2 , Hull Cell test, the electroplating time is 5min, the anode is an electrolytic copper anode, and the cathode is a 5×10cm iron sheet. The plating solution has good stability and is not sensitive to impurities.

[0061] Conduct electroplating experiments on the electroplated test pieces: the deposition rate is: 0.32 μm / min; the current efficiency is 75%; the cove...

Embodiment 3

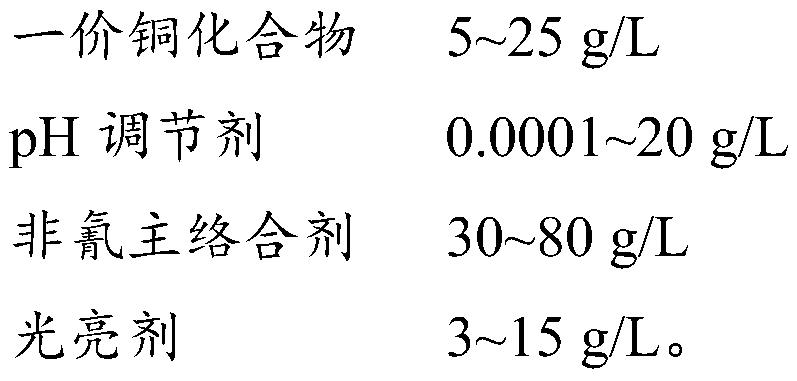

[0063] A kind of cyanide-free alkaline copper plating electroplating solution, it is made of following components:

[0064] The volume of the plating tank is calculated in 1L,

[0065]

[0066] The solvent is deionized water.

[0067] The N'-aminoethyl-benzoylthiourea that present embodiment adopts is synthesized by the method for embodiment 1.

[0068] Prepare 1L cyanide-free alkaline copper plating electroplating solution according to the above scheme, and carry out electroplating and performance testing on it. The experimental conditions are: temperature is 50°C, cathode current density is 1.5A / dm 2 , Hull Cell test, the electroplating time is 8min, the anode is an electrolytic copper anode, and the cathode is a 5×10cm iron sheet. The plating solution has good stability and is not sensitive to impurities.

[0069] Conduct electroplating experiments on the electroplated test pieces: the deposition rate is: 0.30 μm / min; the current efficiency is 76%; the covering abili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com