Heat accumulating type electric heater with heat accumulator formed by casting

A heat storage body, heat storage technology, applied in heating methods, household heating, electric heating systems, etc., can solve the problems of large air thermal resistance, increased difficulty, reduced heat storage, etc., to avoid short circuits and pipe wall. The effect of breakdown, high safety protection level, and improved power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

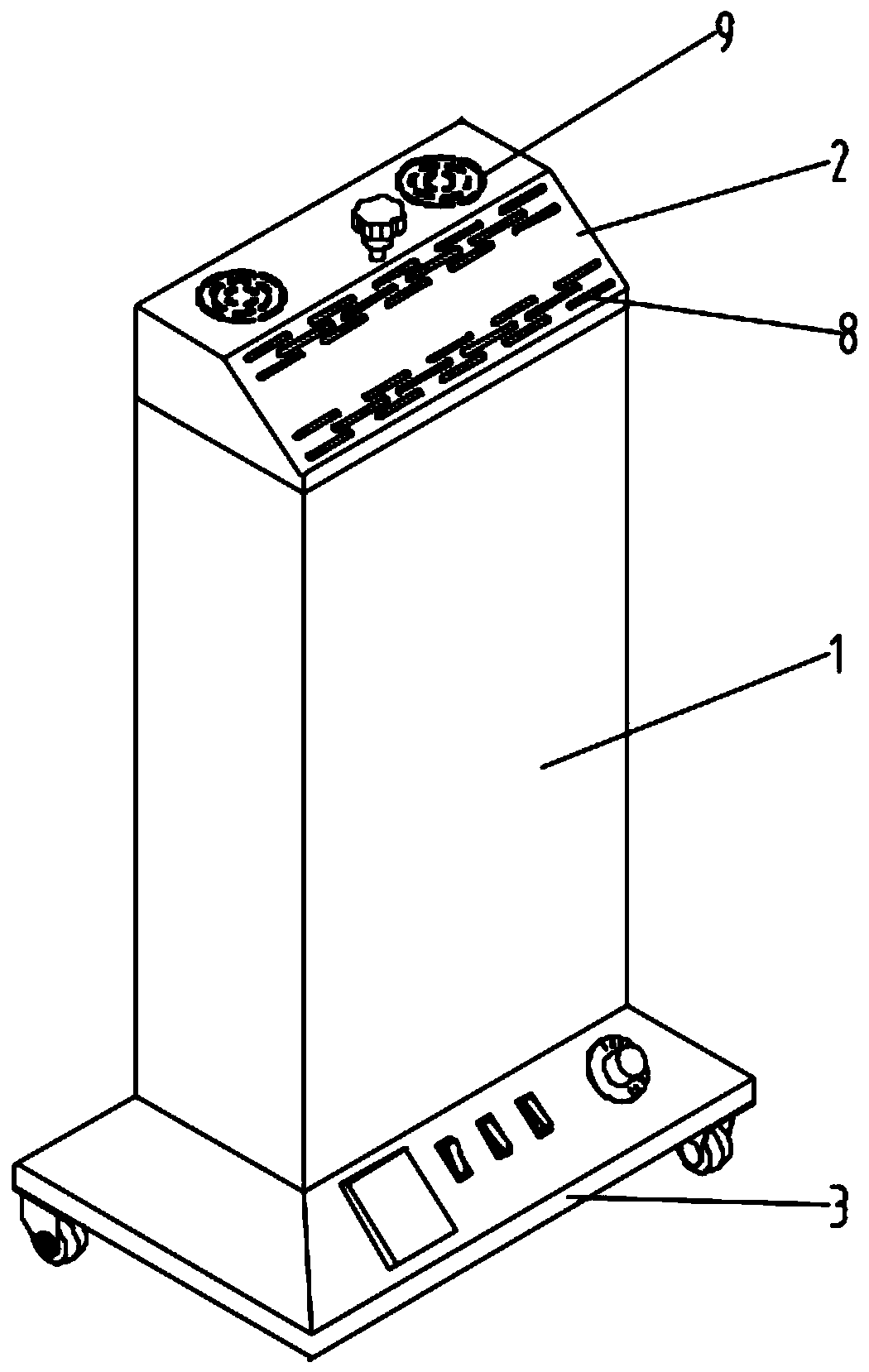

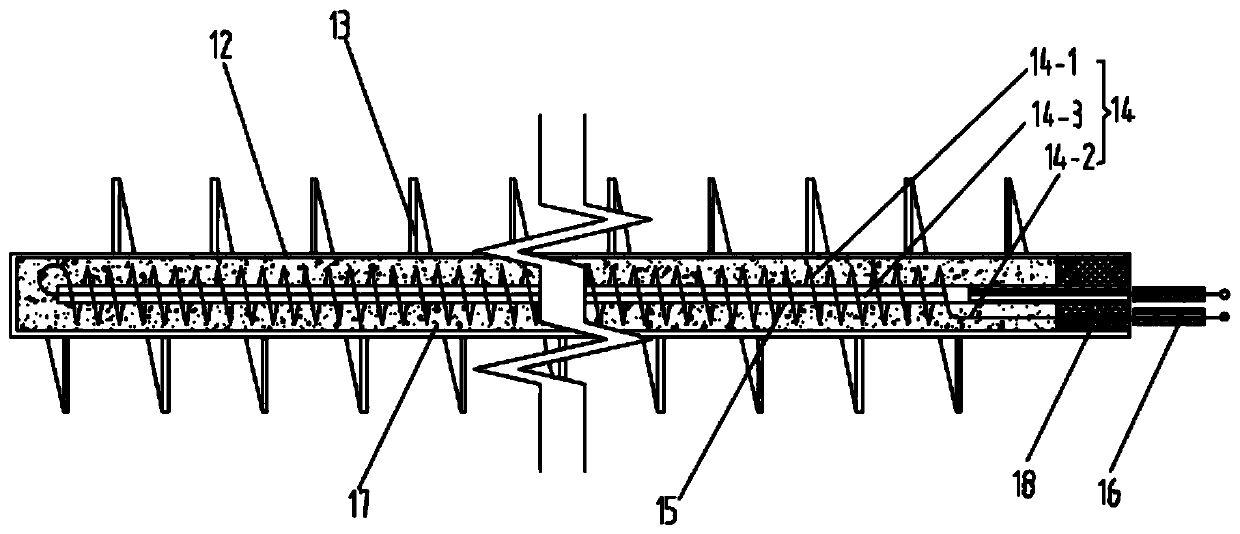

[0047] Such as Figure 1-Figure 2 As shown in the figure, a heat storage type electric heater formed by pouring a heat storage body includes an outer shell 1, a grille cover 2 is arranged above the outer shell 1 to form an air chamber of the electric heater, and the grille cover 2 and the The upper part of the outer casing 1 is dimensionally matched and fastened and connected by anti-loosening screws. And the cross-section of the grille cover 2 is a right-angled trapezoid, and two groups of strip grill holes 8 are symmetrically opened on the front slope of the grille cover, and two sets of circular grille holes are arranged symmetrically on the top of the grille cover 2 . The distributed circular grille holes 9, the hot air generated when the heater is in operation escapes from the strip grille holes 8 and the circular grille holes 9 on the grille cover 2, and forms a circulation with the indoor air.

[0048] A skirt 3 is arranged under the outer casing 1 , and at least one f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com