Polyolefin microporous membrane with improved adhesion performance and production method and application thereof

A polyolefin microporous film and bonding performance technology, which is applied in chemical instruments and methods, structural parts, separators/films/diaphragms/spacers, etc., can solve the problem that the preparation process of wet lithium battery separators is not environmentally friendly and production Due to the difficulty of controlling the preparation process and the defects of the single-layer lithium battery separator, it can improve the wettability and liquid absorption performance, good adhesion and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

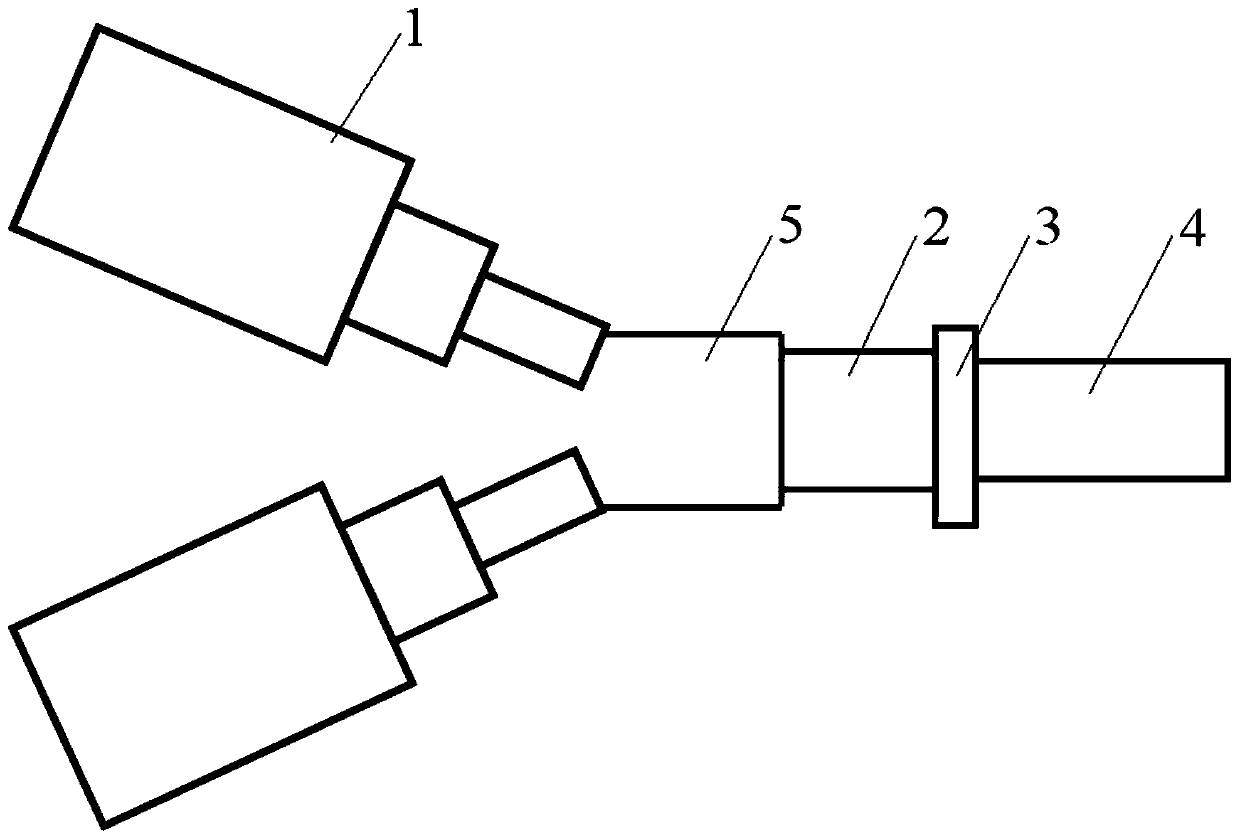

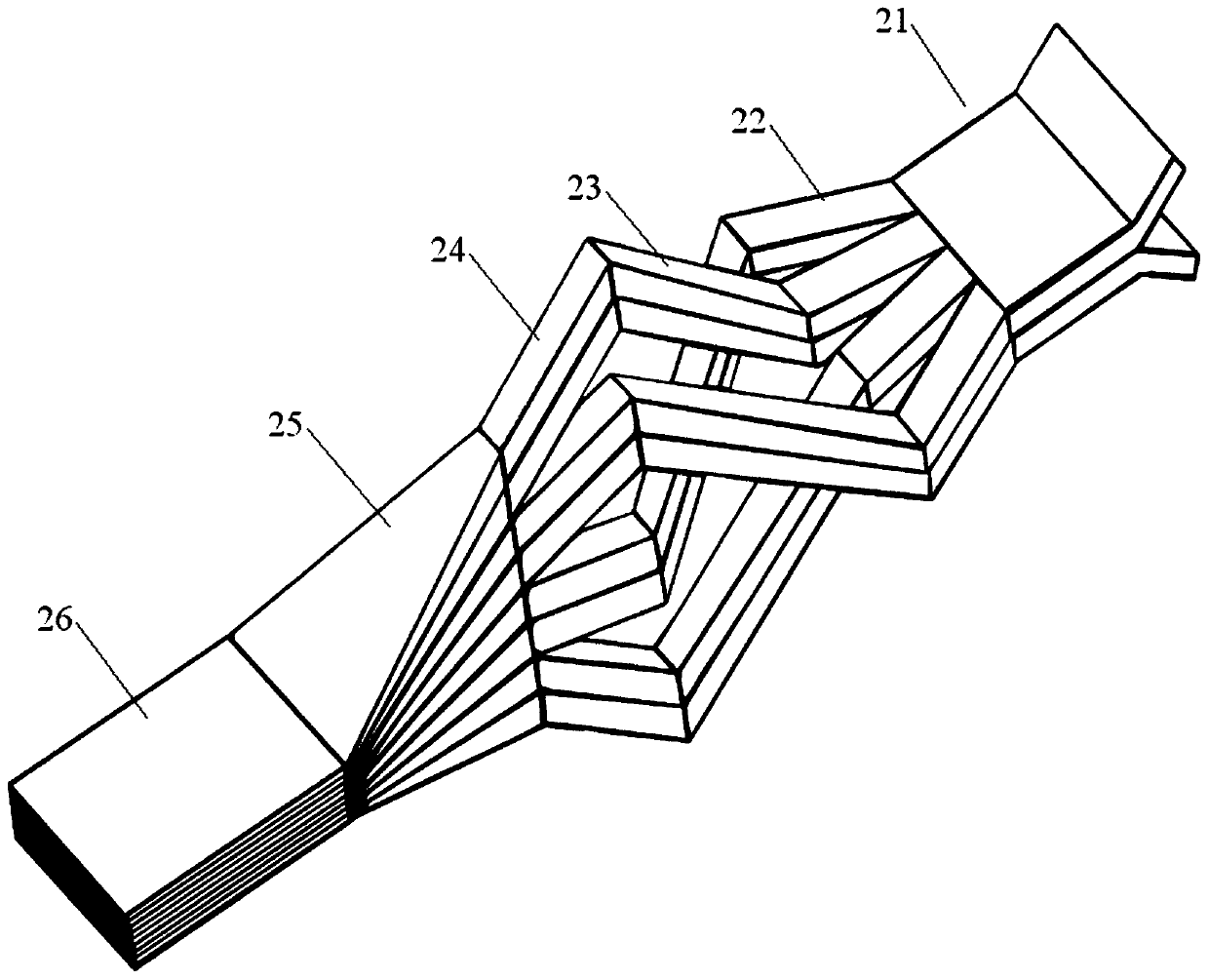

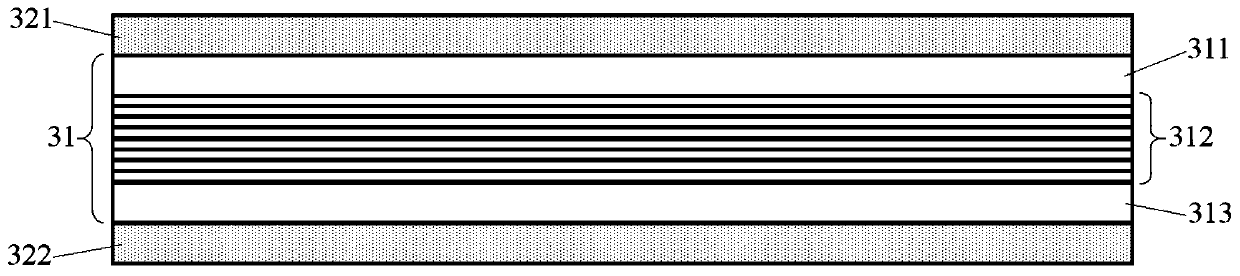

[0049] The polyolefin microporous membrane preparation device of this example, wherein, the part that is used to prepare the middle layer of the multi-layer structure of micro-nano lamination, such as figure 1 As shown, it includes two extruders 1, co-extrusion module 5, micro-nano layer multiplier 2, extrusion die 3 and cooling traction module 4; wherein, two extruders 1 are used to extrude and prepare the middle layer respectively Two different specifications of polypropylene raw materials; the co-extrusion module 5 is set at the output port of the two extruders, and is used to merge and extrude the polyolefin materials extruded by the two extruders, and then transport them to the micro-nano layer The multiplier 2; the micro-nano layer multiplier 2 is a split-layer container as a whole, which is used to divide the molten polyolefin material extruded by the co-extrusion module 5 into several strands, and then each strand forms a layer, and finally forms several layers Laminat...

Embodiment 2

[0064]This example adopts the same device and method of Example 1 to prepare a polyolefin microporous membrane with improved bonding performance. The difference is that the base film of this example has an isotacticity of 98% and a melt index of 1.3g / 10min polypropylene, the lower surface layer is made of polypropylene which is the same as the upper surface layer, the isotacticity of the first polypropylene in the middle layer is 97%, the melt index is 0.8g / 10min, the isotacticity of the second polypropylene is 98%, The melt index was 1.3 g / 10 min. The middle layer is a cross-stacked 16-layer composite structure formed by 8-layer first polypropylene layer and 8-layer second polypropylene layer through micro-nano lamination technology. The preparation of the 16-layer stacked middle layer specifically uses three series-connected micro Nanolayer multiplier. The total thickness of the base film of this example is 16 microns, the thickness of the upper surface layer is 3 microns,...

Embodiment 3

[0067] This example adopts the same device and method as in Example 1 to prepare a polyolefin microporous membrane with improved bonding performance. The difference is that the base film of this example has an isotacticity of 97% and a melt index of 1.5g / It is made of 10min polypropylene, the lower surface layer is made of polypropylene which is the same as the upper surface layer, the isotacticity of the first polypropylene in the middle layer is 98.5%, the melt index is 0.6g / 10min, the isotacticity of the second polypropylene is 97%, The melt index was 1.5 g / 10 min. The middle layer is a cross-stacked 32-layer composite structure formed by micro-nano lamination technology with 16 layers of the first polypropylene layer and 16 layers of the second polypropylene layer. Four series-connected micro Nanolayer multiplier. The total thickness of the base film of this example is 16 microns, the thickness of the upper surface layer is 2 microns, the thickness of the lower surface l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com