3D printing individualized shoe, printing control system and printing control method

A 3D printing and printing control technology, applied in the field of 3D printing, can solve the problems of no uniqueness, no effective enhancement of image resolution, no personalization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In order to further understand the invention content, features and effects of the present invention, the following examples are exemplified, and detailed descriptions are as follows in conjunction with the accompanying drawings.

[0099] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

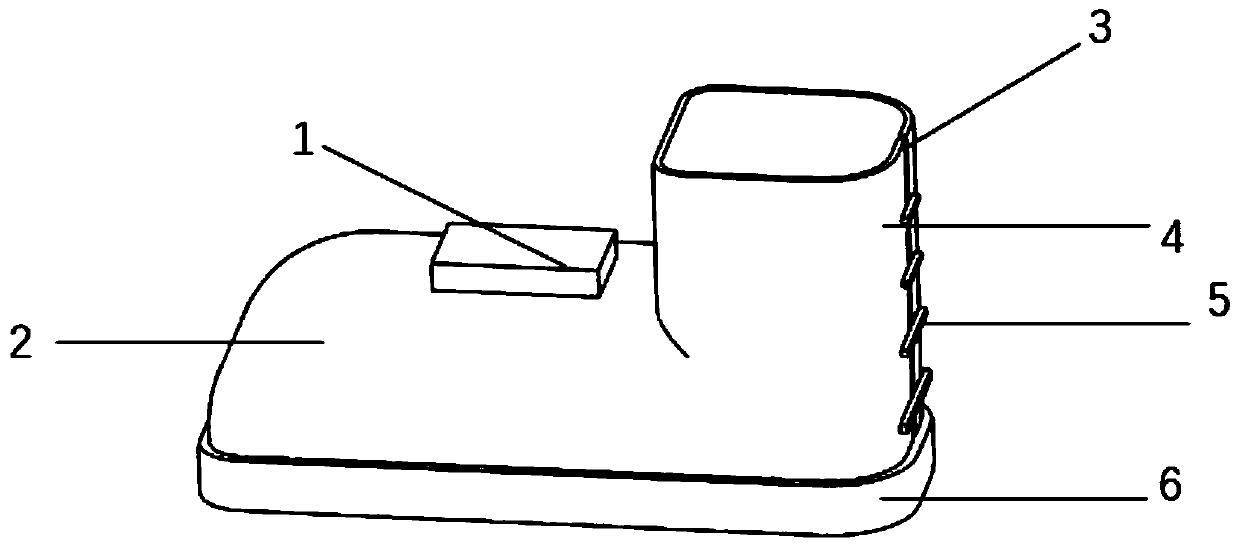

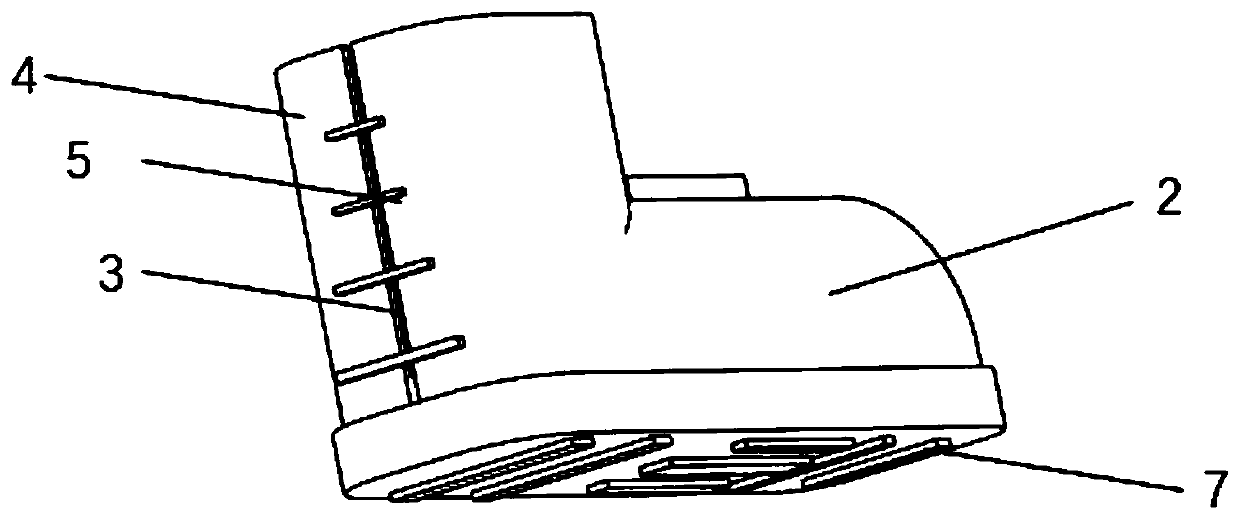

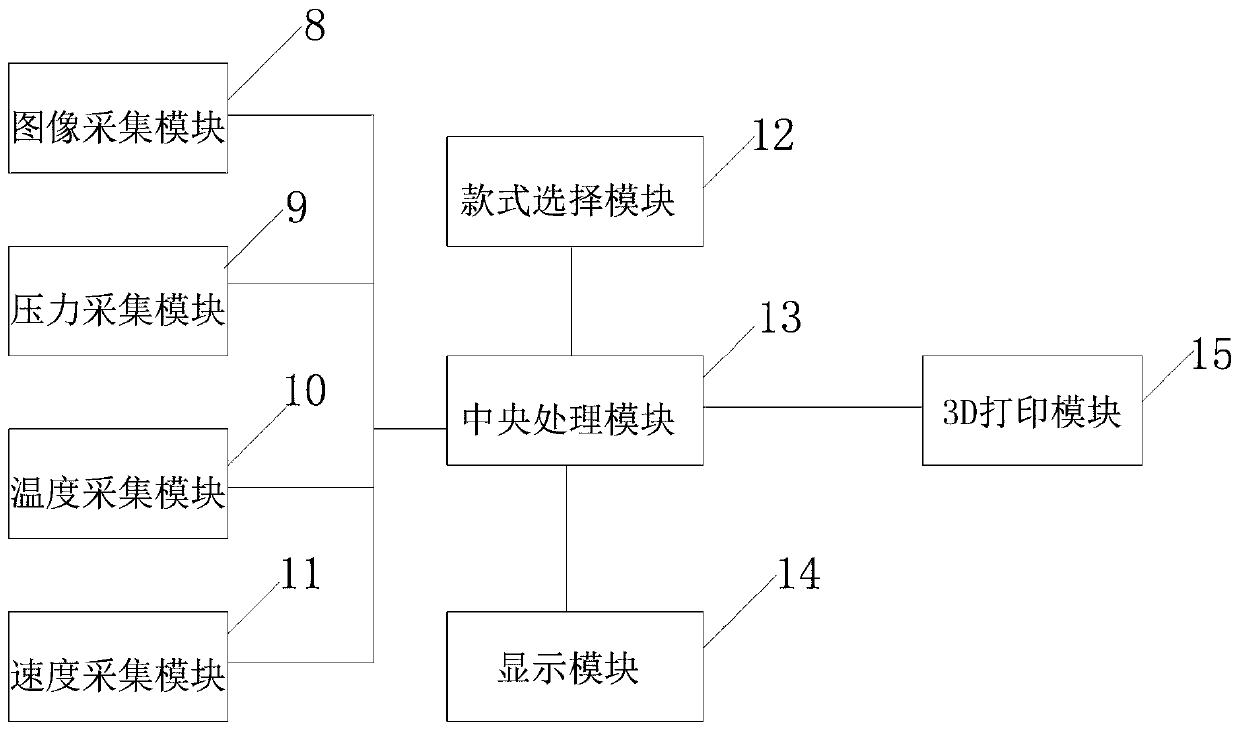

[0100] Such as Figure 1-Figure 2 As shown, the 3D printed personalized shoes provided by the embodiment of the present invention include: a magnetic block 1, an upper 2, a connecting seam 3, a shoe barrel 4, a connecting rope 5, a sole 6, and an anti-skid pattern 7.

[0101] The shoe barrel 4 is glued to the upper 2, the rear of the shoe barrel 4 is slotted with a connecting seam 3, the upper 2 is glued to the sole 6, the upper 2 is clamped with a magnetic block 1, and the sole 6 is provided with anti-skid patterns 7. A connecting rope 5 is worn on the connecting seam 3 .

[0102] The working principle of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com