A flange mold for easy ejection

A technology of ejection and mold, applied in the direction of manufacturing tools, casting molding equipment, casting mold components, etc., can solve the problems of the inner wall of the mold sticking together, time-consuming and labor-intensive mold, rough and not smooth surface, etc., and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

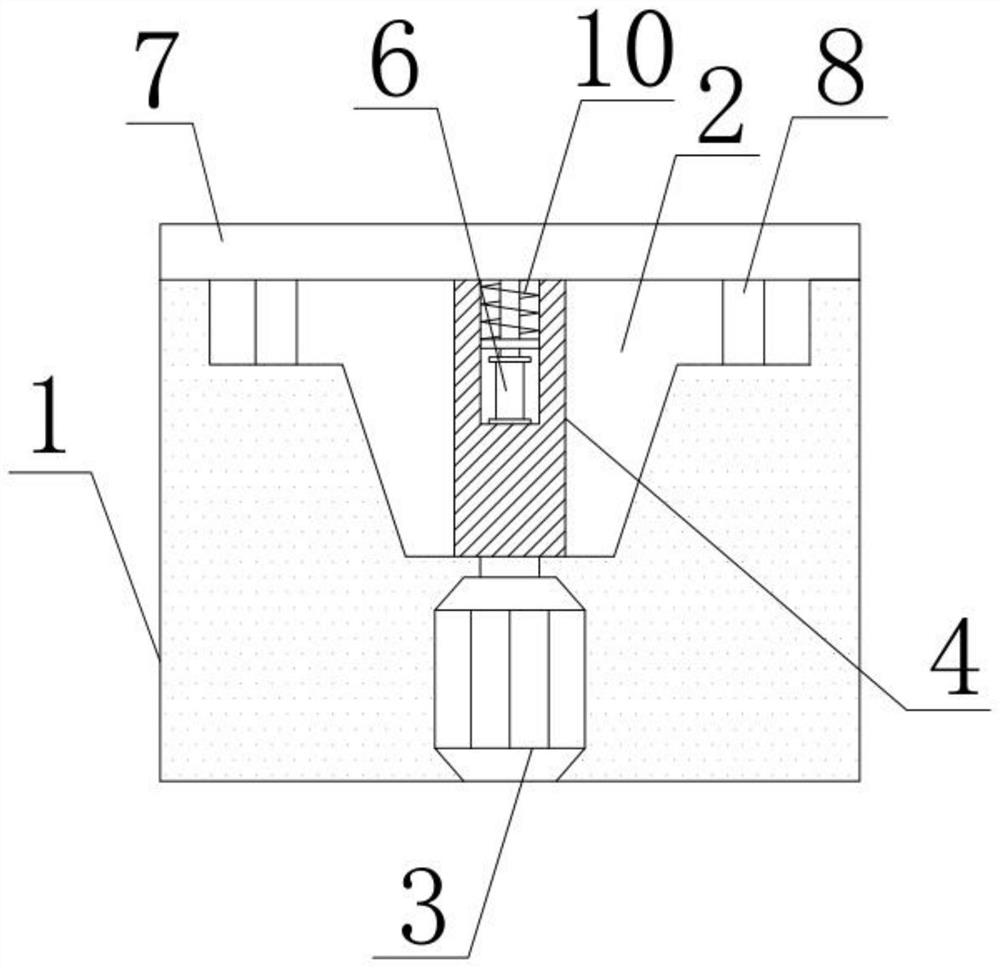

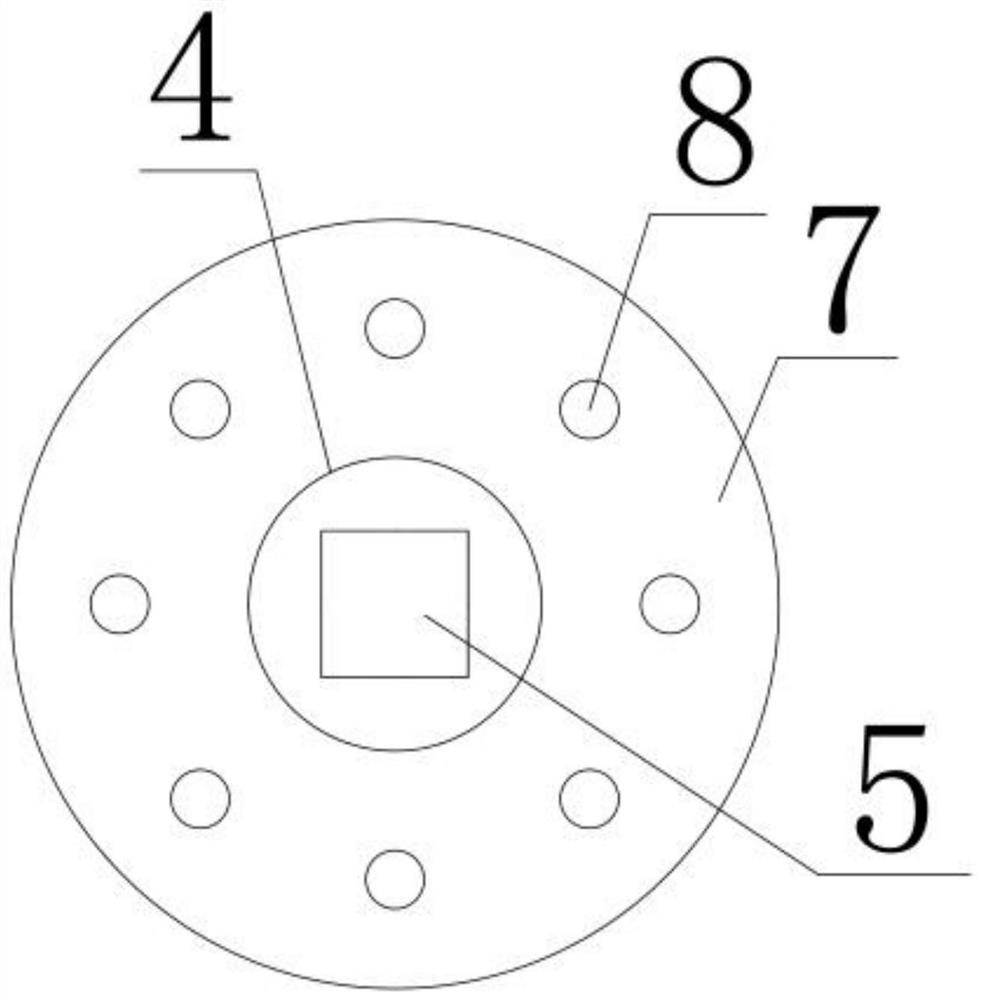

[0017]Please refer toFigure 1-2A convenient flange mold shown, including a mold frame 1, and a prefabricated slot 2 is provided on the top of the mold frame 1, and the motor 3 is fixedly mounted, the motor 3 The power output is passed through the prefabricated slot 2 and is fixedly connected to a circular tube 4 having a square groove 5 having a square groove 5 having a hydraulic cylinder 6, and the power output of the hydraulic cylinder 6 is fixed. The end fixed connection top cover 7, the top cover 7 and the mold frame 1 are all rounded, and a plurality of rods 8 are fixedly mounted in the bottom of the top cover 7, which is noteworthy that the round rod 8 is circulated 4 For the center of the center, the inner wall of the square groove 5 is also fixedly mounted having a fixing plate, and a through hole is opened, and the power output end of the hydraulic cylinder 6 penetrates through the through hole, the top of the fixed plate. A stretch spring 10 is fixedly mounted, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com