Signal terminal embedded power semiconductor module and packaging processing thereof

A technology of power semiconductors and signal terminals, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of terminal load-carrying capacity to be improved, achieve simplified structure and manufacturing process, and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

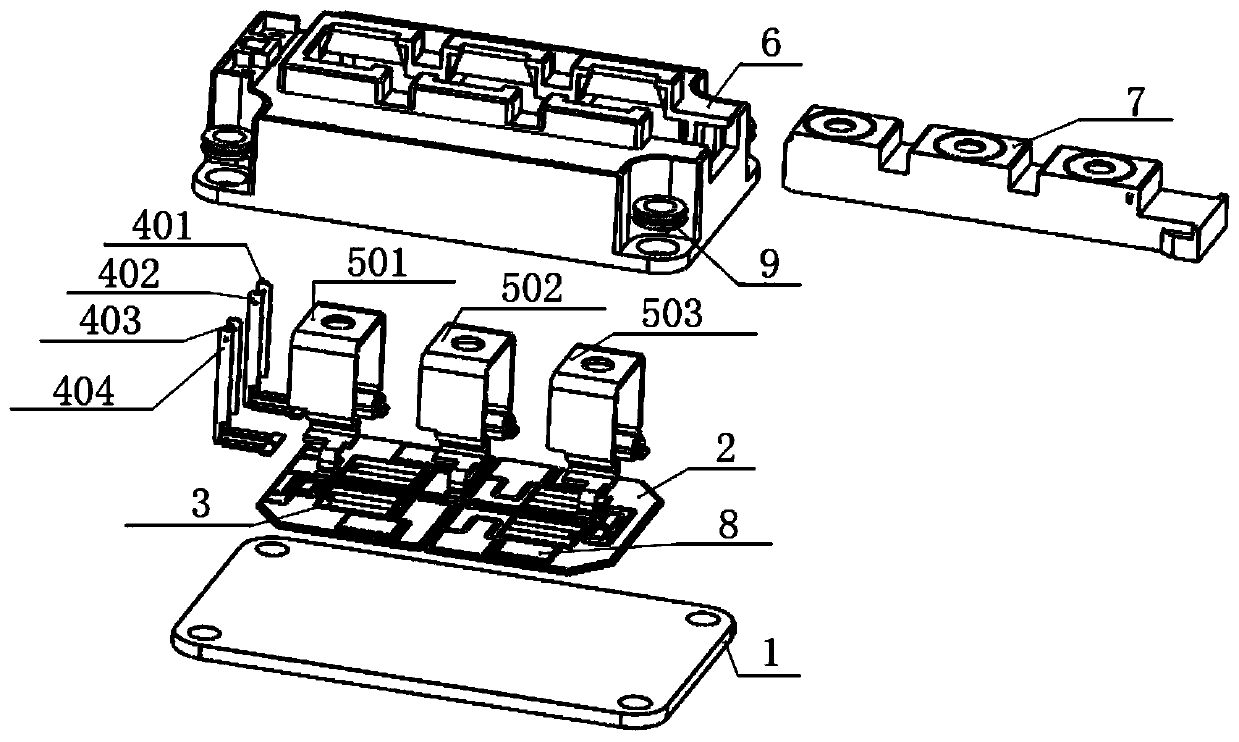

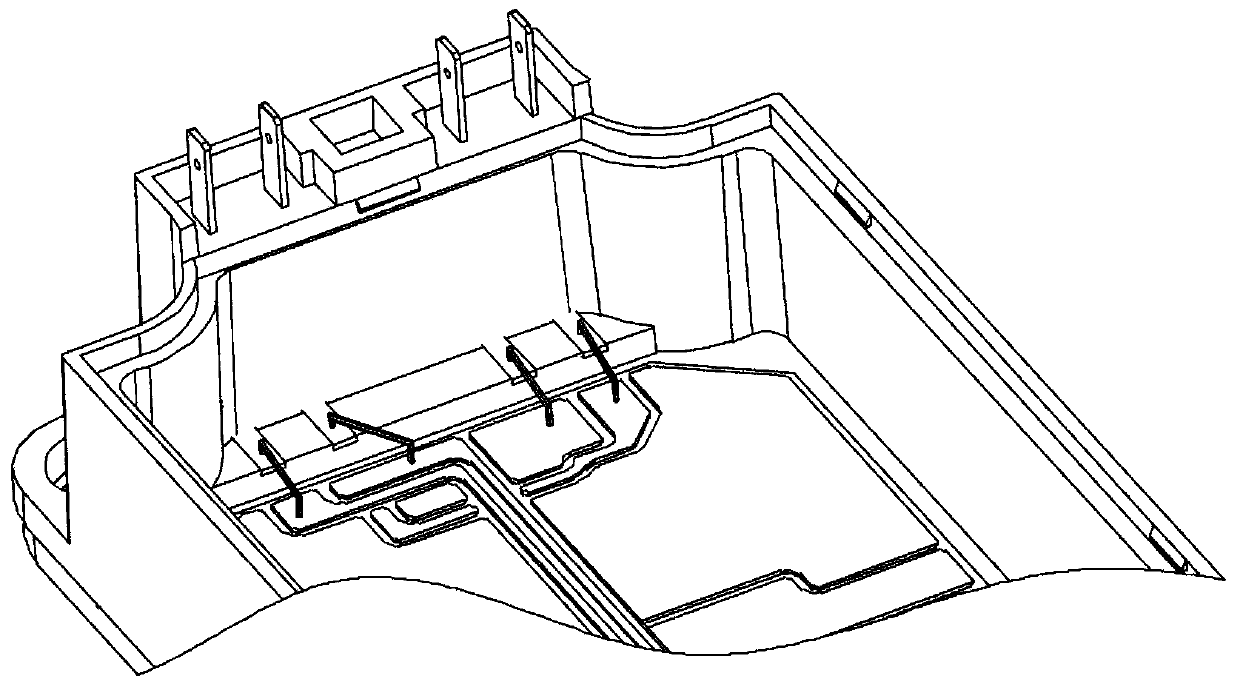

[0018] A signal terminal embedded power semiconductor module, taking the IGBT module as an example, such as figure 1 , figure 2 As shown, it includes a heat dissipation copper plate 1, a ceramic copper clad plate 2 arranged on the heat dissipation copper plate, a power semiconductor chip 3 mounted on the ceramic copper clad plate, and four signal terminals 401- 404 and three power terminals 501-503, and a housing; the housing includes an outer shell 6 and a plug 7, and the plug 7 is inserted into the gap between the two legs of the power terminal; the ceramic copper clad plate Other electronic components, such as diodes 8 , are also welded on it; The signal terminal and the power terminal are made of copper, and the surface is plated with aluminum, silver or nickel. The design of the plug makes it possible to complete the packaging by pushing and pulling, which is more convenient to operate and easy to disassemble and maintain.

[0019] The signal terminals are injection-m...

Embodiment 2

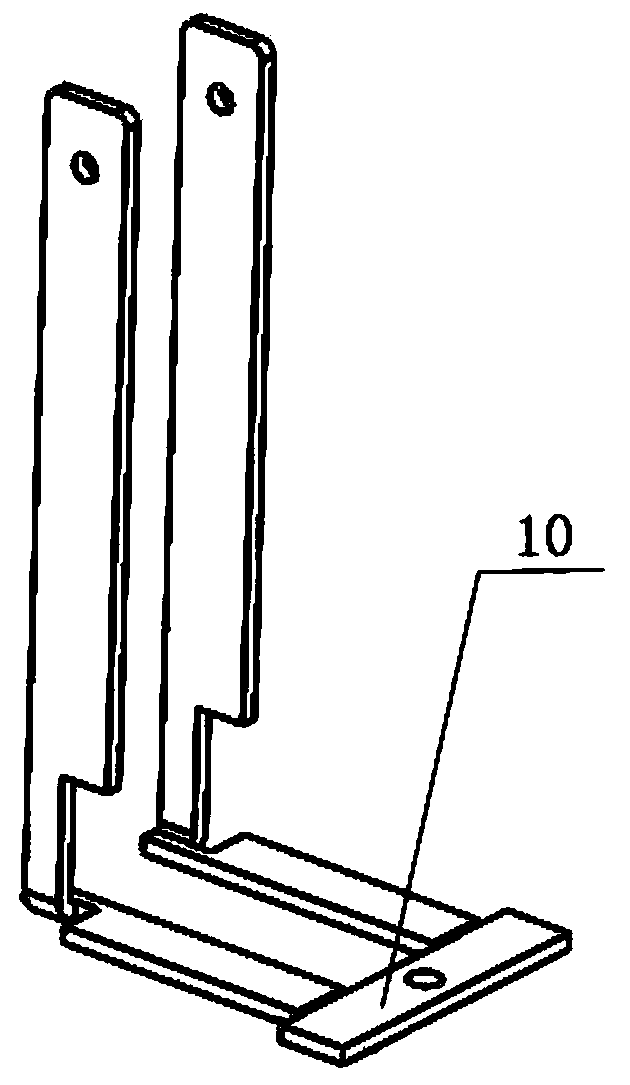

[0025] A packaging process for a signal terminal embedded power semiconductor module, in which two adjacent signal terminals are connected through a connecting bridge, and then integrated with the housing through an injection molding process; after the injection molding process is completed, the connection bridge broken;

[0026] Specifically include the following steps:

[0027] S1: The signal terminal with the connecting bridge is injection molded into one body with the housing;

[0028] S2: Solder the power semiconductor chips and power terminals on the ceramic copper clad board;

[0029] S3: Solder the ceramic copper clad laminate to the heat dissipation copper plate;

[0030] S4: Break off the connection bridge at the bottom of the signal terminal that is integrally molded with the housing, and weld it to the ceramic copper clad board through a bonding process, and adjust the positional relationship between the housing, the heat dissipation copper plate and the power te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com