Computer aided design method for thin-wall copper alloy water meter shell casting process

A computer-aided, casting technology, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve the problems of casting shrinkage, shrinkage, waste of manpower, material resources and time, and different, so as to shorten the trial production time, The effect of reducing trial production cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

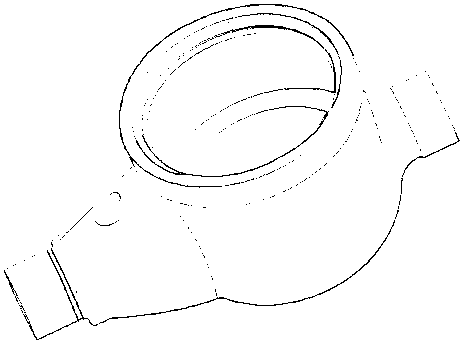

[0029] refer to Figure 1 to Figure 6

[0030] A computer-aided design method for a casting process of a thin-walled copper alloy water meter casing, comprising the following steps:

[0031] (1) Design parts: Design the structure of the copper alloy water meter shell according to the design requirements, and optimize the shell thickness of the copper alloy water meter shell, such as figure 2 shown;

[0032] (2) Design mold: Design the mold according to the structure of the copper alloy water meter shell that has been designed. The design of the mold includes the design of the pouring system, riser and exhaust system. The pouring system adopts stepped pouring. Start to supplement the sprue; set risers at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com