Pit shaft casing-cement sheath cementing surface testing device for high temperature and pressure environments of hot dry rock stratum

A high-temperature, high-pressure, testing device technology, applied in construction and other directions, can solve the problems of reducing the accuracy of ground stress, uneven pressure, interference, etc., and achieve the effect of avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention will be further described.

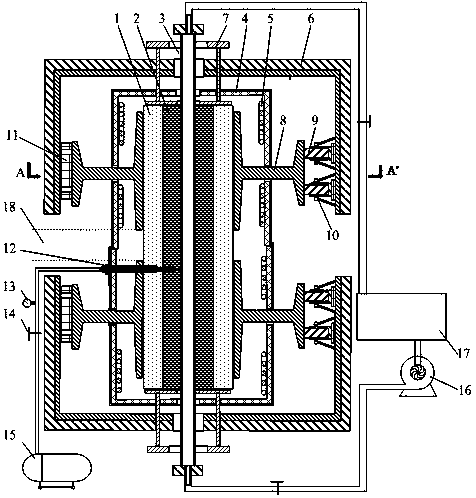

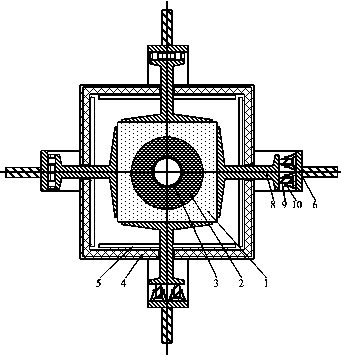

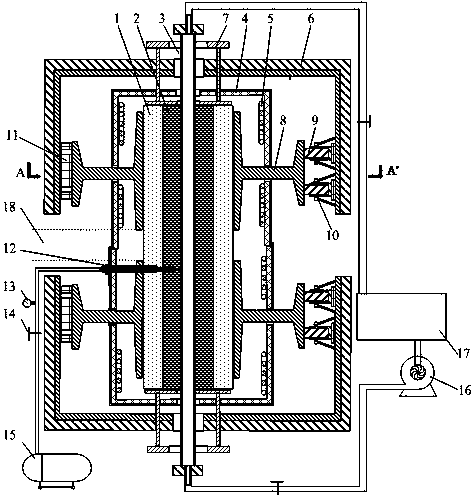

[0030]The preparation method of the wellbore casing-cement sheath cemented surface test device in the high temperature and high pressure environment of the dry hot rock formation specifically includes the following steps: preparing a cuboid rock sample and drilling a hole in the middle of the sample, putting the casing 3 in the center of the drilling hole, and putting the cement The mixture is stirred and poured into the annulus area between the rock and casing 3. Drill a hole at the side of the rock sample, and embed the leakage test interface 12 through the hole into the outer wall of the annulus near the outer wall of the casing; The force transmission member 7 is fixed; the environment box includes an insulation layer 4 and a heating device 5 arranged inside the insulation layer 4 . The horizontal loading force transmission member 8 is connected with the hydraulic cylinder 9 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com