Preparation method of erythromycin thiocyanate

A technology of erythromycin thiocyanate and sodium thiocyanate, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as high pollution, improve product purity, reduce sewage discharge, The effect of reducing the volume of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

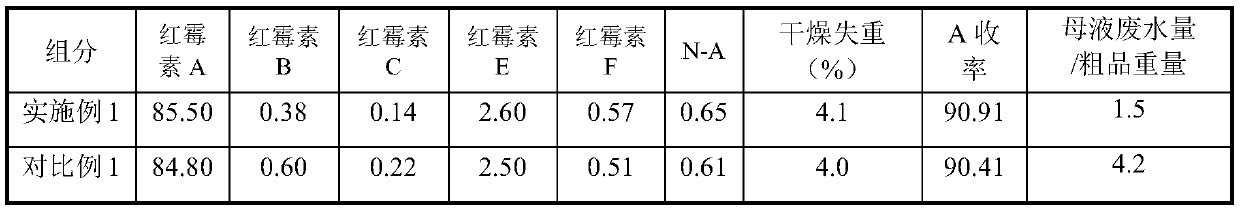

Embodiment 1

[0029] A preparation method of erythromycin thiocyanate, said method comprising the following steps:

[0030] Step 1, get a portion of crude product erythromycin thiocyanate, measure component content, chemical potency, moisture and weight, and calculate the titer billion (u) of this batch of materials.

[0031] Step 2. Add acetone to the reaction kettle, start stirring, and then heat up. When the temperature of the acetone rises to 40° C., put the crude product erythromycin thiocyanate in step 1, and start to slowly add the sodium hydroxide solution dropwise at the same time. The pH value of the final control system is 9.0, and the material temperature is 45°C.

[0032] Step 3, primary phase separation: After the crude product erythromycin thiocyanate dissolves completely, add required sodium chloride (the weight of sodium chloride: crude product erythromycin thiocyanate weight × crude product red thiocyanate) to the system once Loss on drying of mycin × 10%). After adding ...

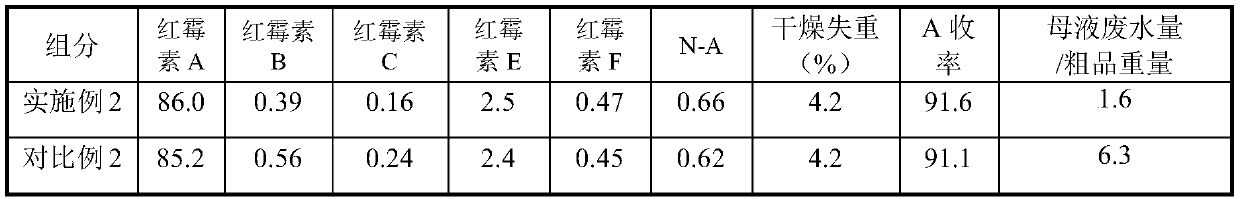

Embodiment 2

[0041] A preparation method of erythromycin thiocyanate, said method comprising the following steps:

[0042] Step 1, get a batch of crude product erythromycin thiocyanate, measure component content, chemical potency, moisture and weight, and calculate the titer billion (u) of this batch of material.

[0043] Step 2, add acetone to the dissolving tank, start stirring, then heat up, when the temperature of acetone rises to 40°C, put the crude product erythromycin thiocyanate in step 1, and start to drop 30% sodium hydroxide solution at the same time , the pH value of the final system is 9.5, and the material temperature is 45°C.

[0044] Step 3, primary phase separation: After the crude product erythromycin thiocyanate dissolves completely, add required sodium chloride (the weight of sodium chloride: crude product erythromycin thiocyanate weight × crude product red thiocyanate) to the system once Loss on drying of mycin × 10%). Stir at 85 rpm for 5 min after adding sodium chl...

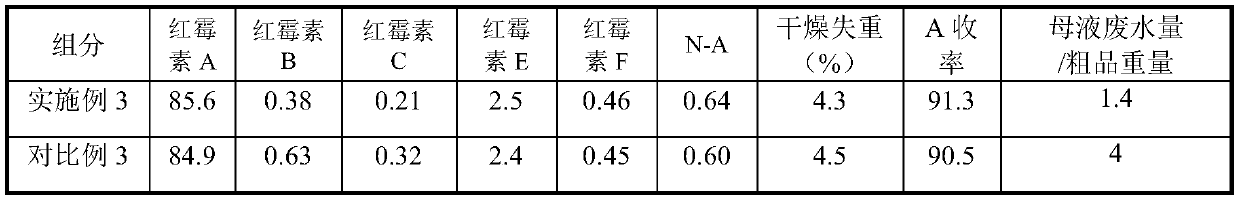

Embodiment 3

[0054] A preparation method of erythromycin thiocyanate, said method comprising the following steps:

[0055] Step 1, get a batch of crude product erythromycin thiocyanate, measure component content, chemical potency, moisture and weight, and calculate the titer billion (u) of this batch of material.

[0056] Step 2. Add a mixture of acetone and dichloromethane (volume ratio = 1:2.0-3.5) into the dissolution tank, start stirring, and then heat up. When the temperature of the mixed solvent rises to 30°C, the crude sulfur in step 1 Erythromycin cyanate was added, and 30% sodium hydroxide solution was added dropwise at the same time, the final system pH was 9.4, and the material temperature was 30°C.

[0057] Step 3, primary phase separation: After the crude product erythromycin thiocyanate dissolves completely, add required sodium chloride (the weight of sodium chloride: crude product erythromycin thiocyanate weight × crude product red thiocyanate) to the system once Loss on dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com