Tropane alkaloid extraction technology

An extraction process and alkaloid technology, applied in the direction of organic chemistry, etc., can solve the problems of unsuitability for large-scale production, underutilization of resources, large amount of organic solvent, etc., achieving high degree of automation, saving labor costs, and improving the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

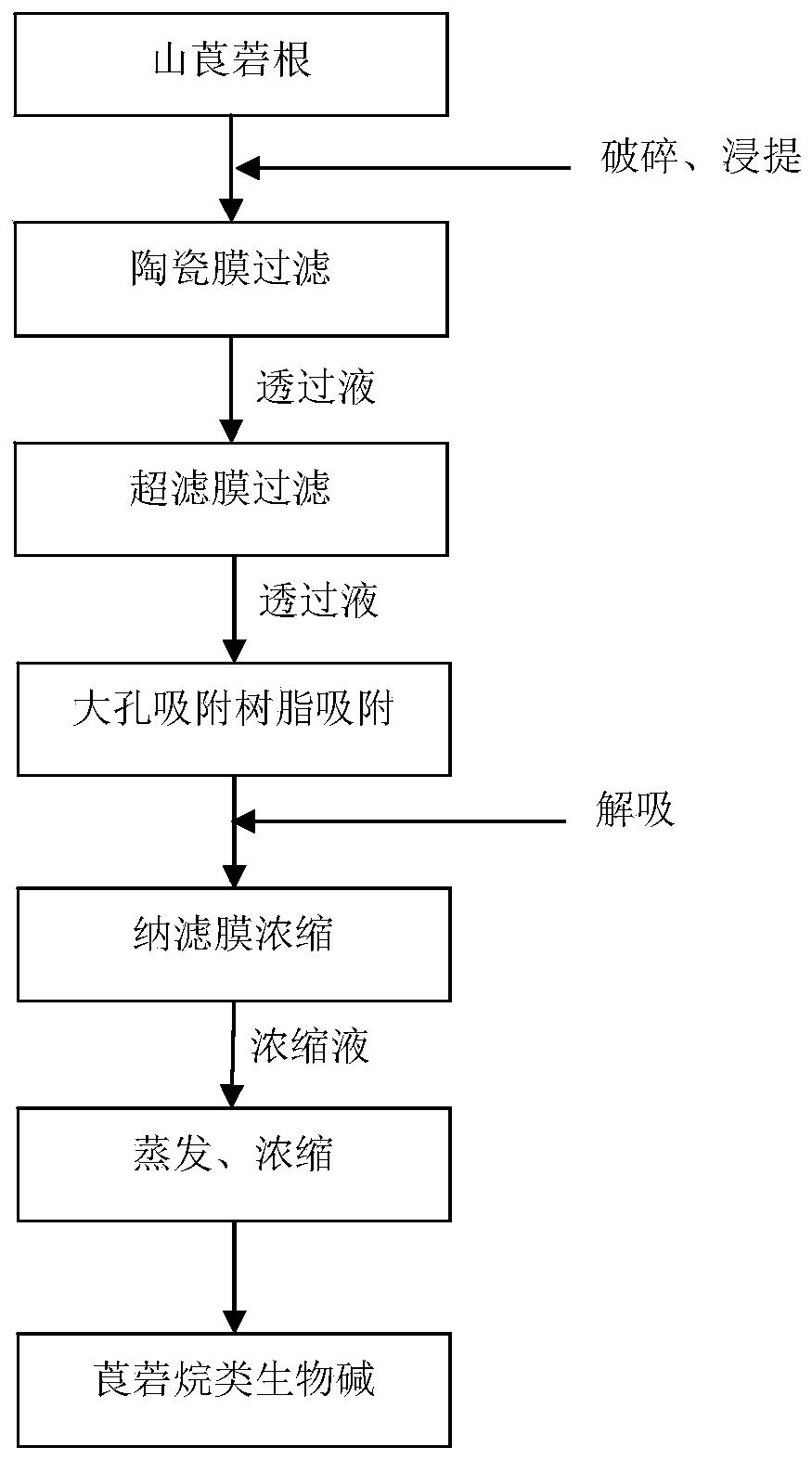

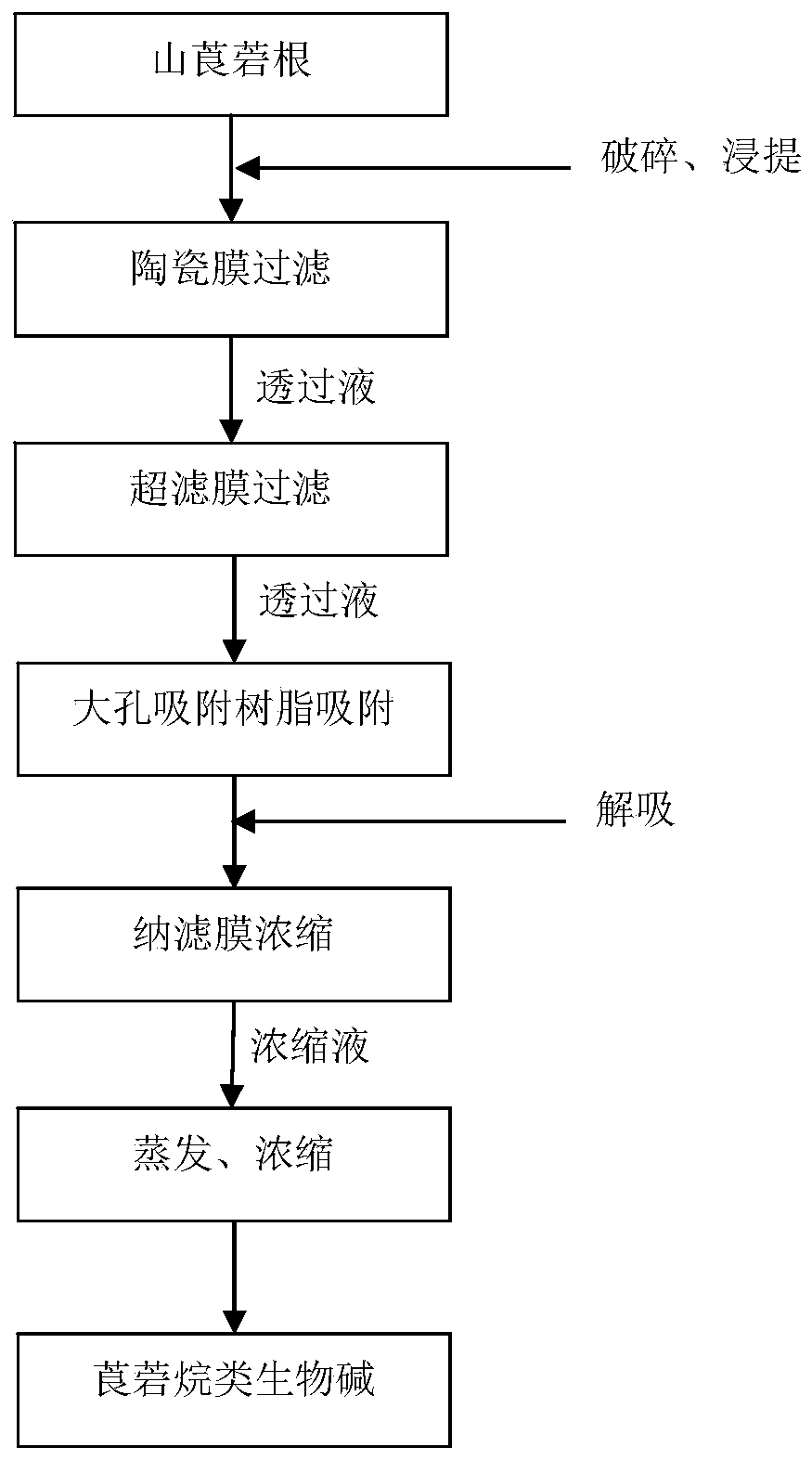

[0035] as per figure 1The flow diagram shown for the extraction of tropane alkaloids:

[0036] (1) After crushing the root of Anisodamine, extract it with an acidic aqueous solution with a pH of 2, and the extraction time is 1 hour. Obtain the crude extract of Anisopolamine root;

[0037] (2) After the crude extract that step (1) obtains is filtered through pre-filter (rectangular filter, filtration precision is 1mm), enter microfiltration membrane (microfiltration membrane is ceramic membrane, and filtration precision is 5nm, and filtration temperature is 10°C, the filtration pressure is 0.1MPa) to obtain the microfiltration membrane permeate;

[0038] (3) The microfiltration membrane permeate obtained in step (2) is filtered and decolorized through an ultrafiltration membrane (the ultrafiltration membrane is a roll-type ultrafiltration membrane, the molecular weight cut-off is 1000Da, the filtration temperature is 10°C, and the filtration pressure is 2.5MPa) , after impur...

Embodiment 2

[0043] as per figure 1 The flow diagram shown for the extraction of tropane alkaloids:

[0044] (1) After crushing the root of Anisodamine, extract it with an acidic aqueous solution with a pH of 5, and the extraction time is 6 hours. Obtain the crude extract of Anisopolamine root;

[0045] (2) After the crude extract that step (1) obtains is filtered through pre-filter (rectangular filter, filtration precision is 3mm), enter microfiltration membrane (microfiltration membrane is ceramic membrane, and filtration precision is 500nm, and filtration temperature is 80°C, filtration pressure is 0.8MPa) to obtain microfiltration membrane permeate;

[0046] (3) The microfiltration membrane permeate obtained in step (2) is filtered and decolorized through an ultrafiltration membrane (the ultrafiltration membrane is a roll-type ultrafiltration membrane, the molecular weight cut-off is 20000Da, the filtration temperature is 60°C, and the filtration pressure is 0.5MPa) , after impurity...

Embodiment 3

[0051] as per figure 1 The flow diagram shown for the extraction of tropane alkaloids:

[0052] (1) After crushing the root of Anisodamine, extract it with an acidic aqueous solution with a pH of 3 for 5 hours. Obtain the crude extract of Anisopolamine root;

[0053] (2) After the crude extract that step (1) obtains is filtered through pre-filter (rectangular filter, filtration precision is 5mm), enter microfiltration membrane (microfiltration membrane is ceramic membrane, and filtration precision is 50nm, and filtration temperature is 80°C, the filtration pressure is 0.4MPa) to obtain the microfiltration membrane permeate;

[0054] (3) The microfiltration membrane permeate obtained in step (2) is filtered and decolorized through an ultrafiltration membrane (the ultrafiltration membrane is a roll-type ultrafiltration membrane, the molecular weight cut-off is 10000Da, the filtration temperature is 30°C, and the filtration pressure is 0.5MPa) , after impurity removal, the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com