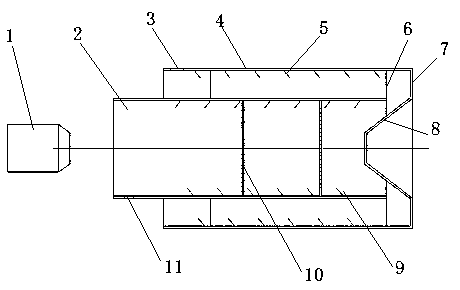

Phosphogypsum calciner

A calcining furnace and phosphogypsum technology, applied in the field of phosphogypsum calcination, can solve the problems of environmental pollution of phosphogypsum, enlarged diameter of flame-throwing furnace, and inability to be directly applied, etc., and achieve the effects of reducing impact, smooth movement, and maintaining airflow balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

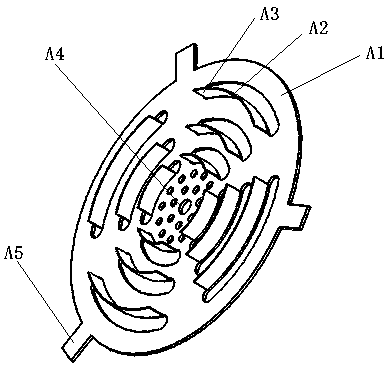

[0018] Embodiment 2. In this example, the same support body as in Embodiment 1 is selected as the support body A1 of this example, the connecting frame is used as the connecting frame A5 of this example, and the middle damping hole is used as the middle damping hole A4 of this example. The long hole is used as the outer peripheral damping hole A2 in this example, and the air deflector A3 is arranged on the inner edge of the outer peripheral damping hole A2, and the wind deflector A3 is guaranteed to be inclined to the outer circumference of the support body A1, so that the outer peripheral damping hole The hot air flowing out from A2 is guided to the direction of the inner wall of the inner cylinder 2; according to the selection and installation method of the calciner in the first embodiment, the calciner is assembled and installed, and two pressure equalizing devices 10 of this example are selected, according to the embodiment The first position is installed in the inner tube ...

Embodiment 3

[0019] Embodiment three, in this example, the main body of the calciner is selected to be the same as that in embodiment one, except that the pressure equalizing device 10 is used. In this example, the same connecting frame as in embodiment one is selected as the connecting frame B6 of this example, and a part of the ring is used as the connecting frame B6. Outer circular support B1, its ring is made of steel plate, the outer diameter of the ring is 1800 mm, the inner diameter is 1700 mm, and the thickness is 5 mm; the diameter of the large end of the tapered support B2 is 1700 mm, and the diameter of the small end is 500 mm , with a height of 500 mm; it is rolled and welded by punching steel plate with a thickness of 3 mm, and the diameter of the punching hole is 30 mm, and the distance between the two holes is 50 mm. A circular steel plate with a diameter of 5 mm and a diameter of 500 mm is used as the middle support body B4, and it is welded to the small end of the tapered s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com