Automobile transporting device and working process thereof

A transportation device and automobile technology, applied in the field of transportation, can solve the problems of reduced electrical connection efficiency, reduced mechanical connection efficiency, and low energy utilization rate, so as to increase the average travel speed, reduce the power supply path, and improve the power utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

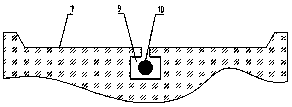

[0040] The vehicle train 3 is composed of traction vehicles 1 and electric vehicles 2 . The traction vehicle 1 is provided with a power collecting device 5, and the traction vehicle 1 is provided with a flexible traction device 10, and a plurality of semi-connection devices 4 and electrical connection devices 8 fixedly connected thereto are distributed on the traction device 10, and the electrical connection device 8 is electrically The collector device 5 is connected; the road 7 is provided with a guide groove 9, and the traction device 10 is arranged in the guide groove 9 of the road 7 if it does not protrude from the road surface, and the guide groove 9 is arranged under the road surface; The device 4 and the electrical connection device 8, the semi-connection device 4 and the electrical connection device 8 correspond to the combination and separation of the semi-connection device 4 and the electrical connection device 8 provided with the traction device 10; the road 7 is al...

Embodiment 2

[0042] The automobile train 3 is composed of a traction vehicle 1 and a plurality of electric automobiles 2 . The traction vehicle 1 is provided with a power collecting device 5, and the rear end of the traction vehicle 1 is provided with a semi-connecting device 4 and an electrical connecting device 8 fixedly connected thereto, and the electrical connecting device 8 is conductively connected to the current collecting device 5; the front and rear of the electric vehicle 2 The two ends are also respectively provided with a half-connection device 4 and an electrical connection device 8 correspondingly, and the vehicles are arranged in the order of end-to-end connection, correspondingly combining the half-connection device 4 and the electrical connection device 8; the road 7 is also provided with a corresponding power supply The catenary 6 of the traction vehicle 1 is electrically connected to the catenary 6, so as to obtain external electric energy to drive the traction vehicle 1...

Embodiment 3

[0044] A kind of operation method of the automobile train 3 described in embodiment 1 and 2, described traction vehicle 1 or automobile train 3 travel in the circle direction on the circular road 11 that connects end to end, image 3 It is a schematic diagram of a ring road; the ring road 11 is provided with a ramp 12 to connect, and the electric vehicle 2 changes the direction of travel through the ramp 12; the ring road 11 is connected with the external road through the ramp 12; the traction vehicle 1 and the electric vehicle 2 are provided with an automatic driving device, The traction vehicle 1 or the automobile train 3 travels along the circular road 11, and the electric vehicles 2 are connected or disconnected during driving, and are incorporated into or disengaged from the automobile train 3 without stopping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com