Double-station wire-drawing treatment equipment for aluminum material

A processing equipment and dual-station technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of suspension of the drawing process, reduced drawing efficiency, and inability to draw profiles, and achieve reasonable structural design and improved The effect of drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

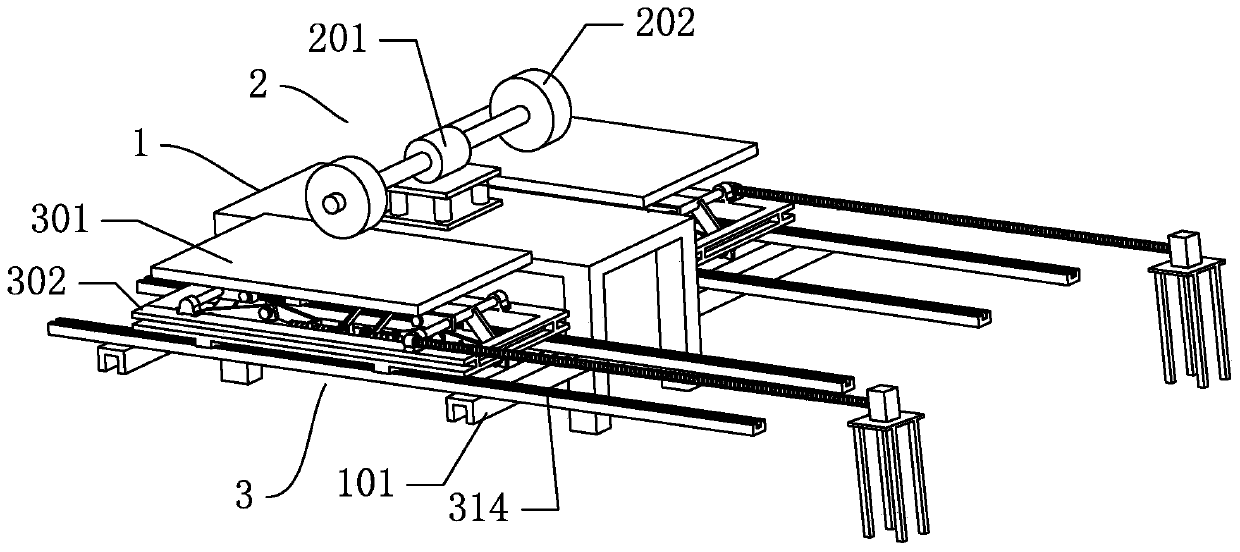

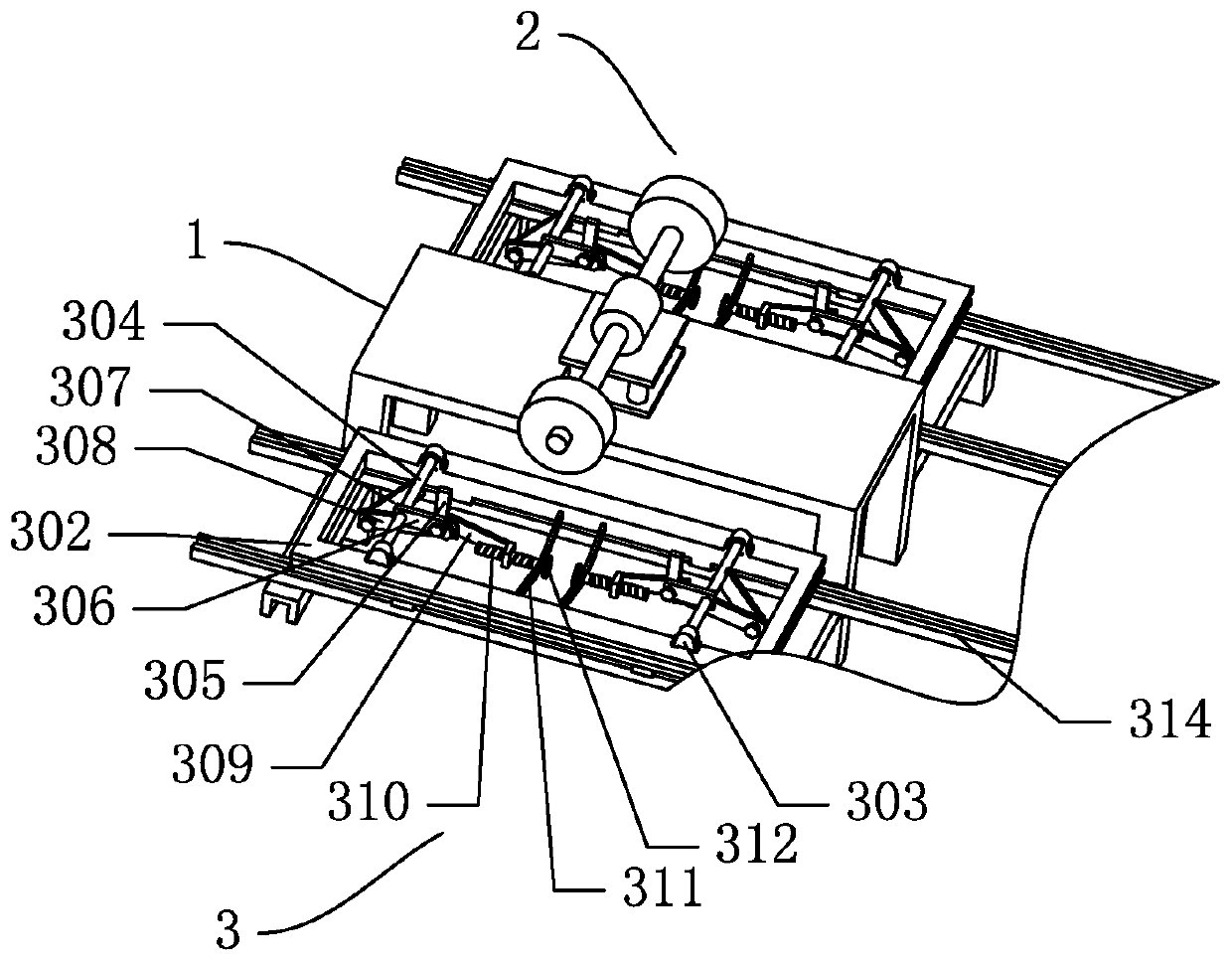

[0056] Such as Figure 1-2 As shown, a double-station aluminum wire drawing processing equipment includes:

[0057] A support base 1, the support base 1 includes four legs and a rectangular support plate, and a mounting plate 102 is also provided between the legs;

[0058] The workpiece disk 202, the workpiece disk 202 is arranged on the support plate of the support seat 1, the workpiece disk 202 is set to two, and the two workpiece disks 202 are symmetrically and horizontally arranged, and the workpiece disk 202 can use a grinding wheel, or according to the different profiles of the wire drawing Nylon grinding wheels can also be used;

[0059] Alternatively, one of the two workpiece discs 202 is equipped with a grinding wheel, and the other is equipped with a polishing abrasive tool, so that wire drawing and polishing can be realized on one machine at the same time, so that one machine can be used for two purposes.

[0060] The drive unit 2, the drive unit 2 adopts a double...

Embodiment 2

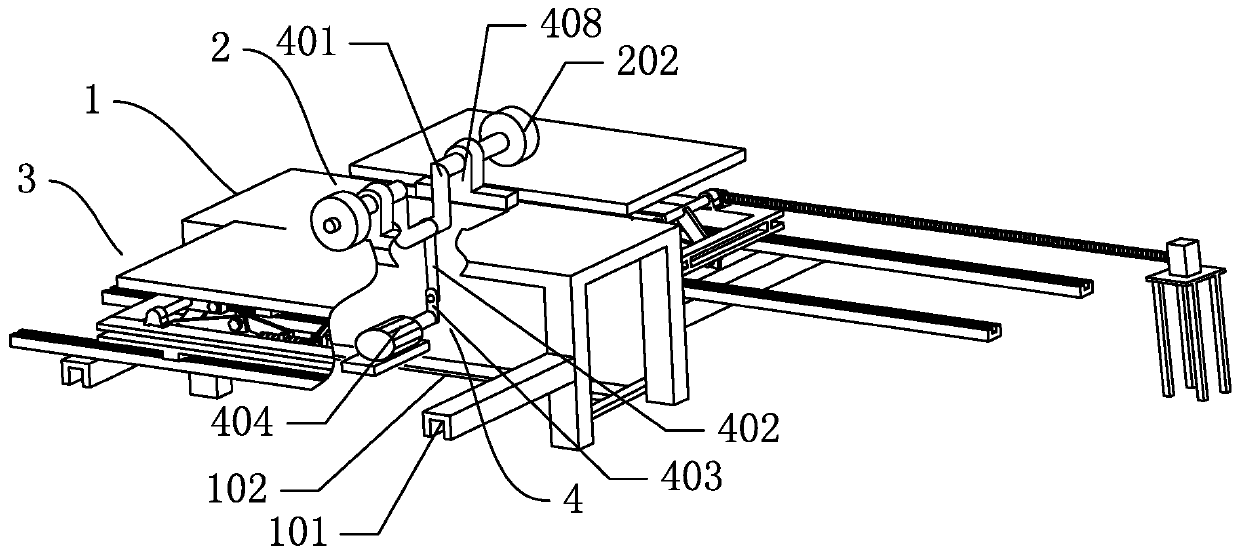

[0072] This embodiment is a replacement for the transmission mechanism 4 in the first embodiment.

[0073] Such as image 3 As shown, specifically, the transmission mechanism 4 includes two spaced apart and symmetrically arranged bearing seats 408 , of course, multiple bearing seats 408 may also be provided. The support seat 1 between the two bearing seats 408 is provided with an opening of a strip rectangular structure, the bearing seat 408 is arranged on the upper surface of the support seat 1, and bearings are respectively arranged in the two bearing seats 408, and a crankshaft 401 The two ends pass through two bearing housings 408 and are connected with two grinding wheels. The crankshaft position of the crankshaft 401 is hinged with a first connecting rod 402, and the other end of the first connecting rod 402 is hinged with a crank 403. The other end of the crank 403 is connected to the set The first motor 404 on the support base 1 is fixedly connected, and the first con...

Embodiment 3

[0075] Such as Figure 5 As shown, this embodiment is a replacement for the transmission mechanism 4 in Embodiment 1.

[0076] Specifically, the transmission mechanism 4 includes a second motor 405, the second motor 405 is arranged on the upper surface of the support base 1, the output shaft of the second motor 405 is fixedly connected with a first bevel gear 406, and the first bevel gear 406 Cooperating with the two second bevel gears 407, the two bevel gears 407 are connected with the two grinding wheels through transmission shafts to drive the two grinding wheels to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com