Target rolling method

A target and blank technology, which is applied in metal rolling, metal rolling, tool manufacturing, etc., can solve the problems of affecting the coating quality, target sputtering performance needs to be improved, target sputtering performance restricts coating mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It can be seen from the background technology that the sputtering performance of existing targets still needs to be improved.

[0029] An analysis is now made in conjunction with a target rolling method. The process steps of the target rolling method mainly include: providing a target blank; performing heat treatment on the target blank; , performing a calendering process on the target blank until the target blank is made into a target material.

[0030] The sputtering performance of the target material rolled by the above method is poor. The reason for the analysis is that although the heat treatment can reduce the hardness of the target material blank, during the rolling process, as the target material The temperature of the blank gradually decreases, and the hardness of the target blank gradually increases, causing cracks to easily appear in the target blank during the rolling process, affecting the rolling quality of the target blank, causing the target blank to po...

PUM

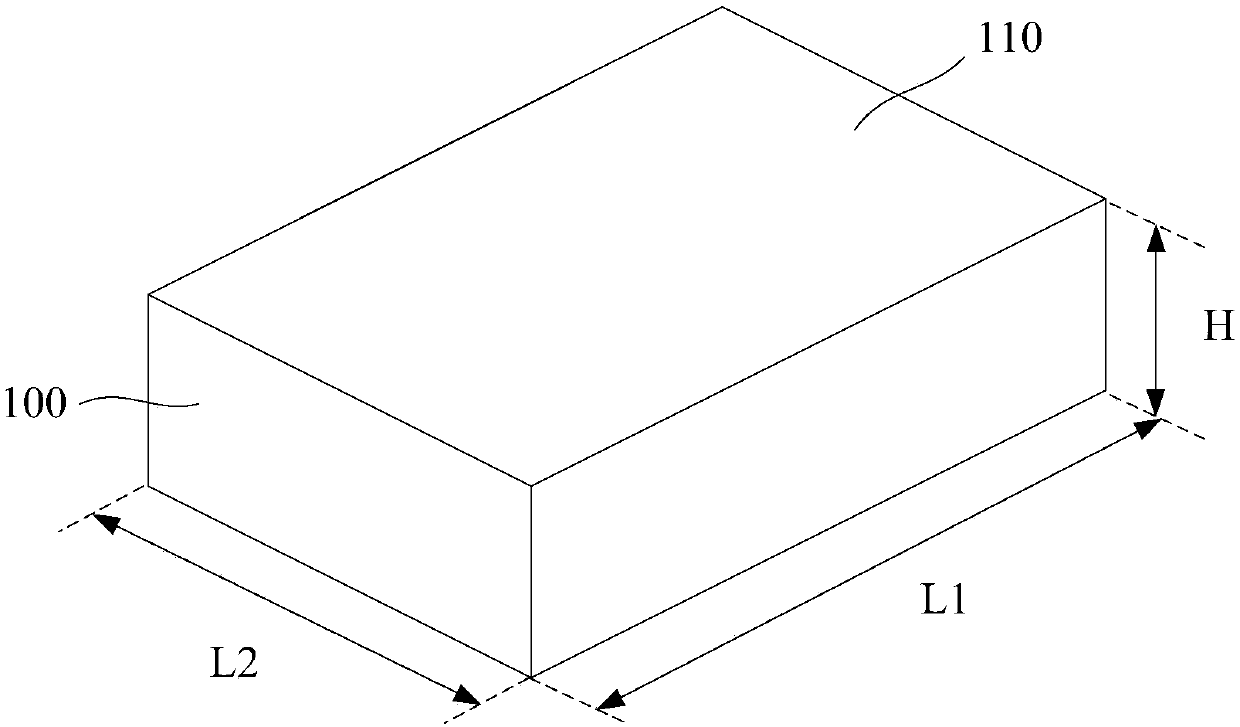

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com