Preparation method of microspheric ZnO-BiOI composite material

A composite material, spherical technology, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve the problems of poor photocatalytic activity, large limitations, complex processes, etc., and achieve a simple and easy preparation process. , Excellent photocatalytic performance, high photocatalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment is about a preparation method of microspherical ZnO-BiOI composite material, which comprises the following steps:

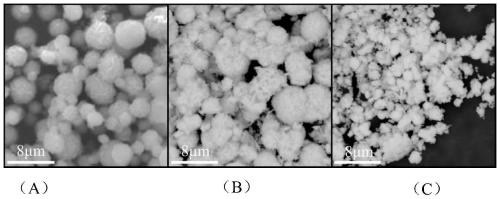

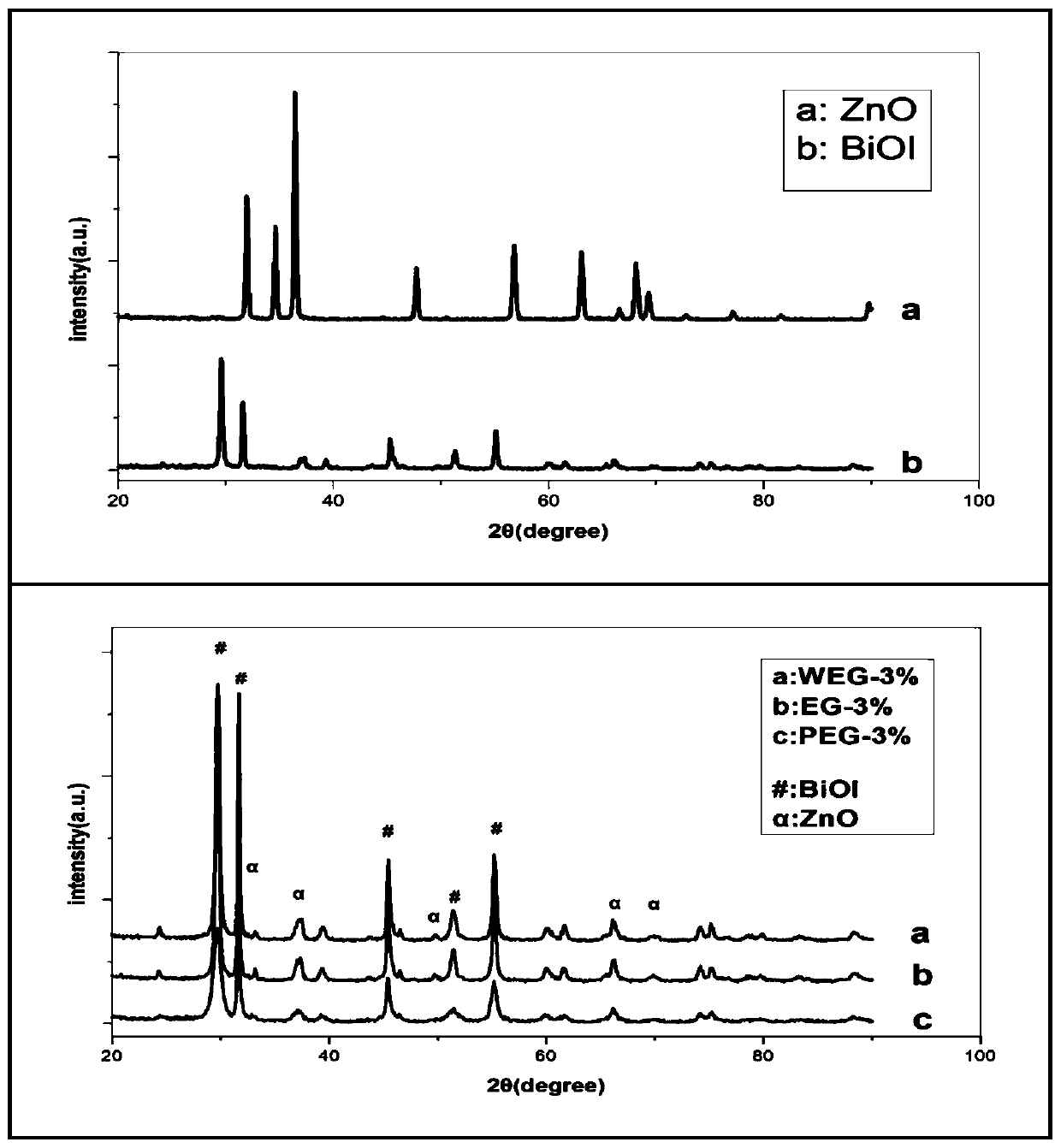

[0045] (1) ZnO with a purity of more than 99.9% is selected as the initial raw material, which is denoted as A-ZnO. Among them: the microscopic appearance of A-ZnO is a rod-like structure with a particle size of 30nm, the macroscopic appearance of A-ZnO is white powder, and its X-ray diffraction diagram is shown in figure 2 .

[0046] (2) Take an appropriate amount of A-ZnO and place it in a crucible, treat it in a muffle furnace at 500°C for 10 minutes, then take it out and cool it to room temperature, and the obtained product is designated as B-ZnO.

[0047] (3) Weigh 12.50g of B-ZnO and 1.25g of NaH respectively 2 PO 4 Disperse them evenly in 500mL of 0.5mL / mL ethanol aqueous solution, stir magnetically and boil and reflux for 8h. Drying at lower temperature for 4h to obtain P-ZnO;

[0048] (4) Weigh 0.26 g of P-ZnO and ultrasonica...

Embodiment 2

[0053] This embodiment is about a preparation method of microspherical ZnO-BiOI composite material, which comprises the following steps:

[0054] (1) ZnO with a purity of more than 99.9% is selected as the initial raw material, which is denoted as A-ZnO. Among them: the microscopic appearance of A-ZnO is a rod-like structure with a particle size of 30nm, the macroscopic appearance of A-ZnO is white powder, and its X-ray diffraction diagram is shown in figure 2 .

[0055] (2) Take an appropriate amount of A-ZnO and place it in a crucible, treat it in a muffle furnace at 450°C for 15 minutes, then take it out and cool it to room temperature, and the obtained product is designated as B-ZnO.

[0056] (3) Weigh 10.00g of B-ZnO and 0.50g of NaH respectively 2 PO 4 And they were uniformly dispersed into 500mL of 0.4mL / mL ethanol aqueous solution, magnetically stirred and boiled and refluxed for 6h. Drying at lower temperature for 5h to obtain P-ZnO;

[0057] (4) Weigh 0.26 g of...

Embodiment 3

[0062] This embodiment is about a preparation method of microspherical ZnO-BiOI composite material, which comprises the following steps:

[0063] (1) ZnO with a purity of more than 99.9% is selected as the initial raw material, which is denoted as A-ZnO. Among them: the microscopic appearance of A-ZnO is a rod-like structure with a particle size of 30nm, the macroscopic appearance of A-ZnO is white powder, and its X-ray diffraction diagram is shown in figure 2 .

[0064](2) Take an appropriate amount of A-ZnO and place it in a crucible, treat it in a muffle furnace at 550°C for 8 minutes, then take it out and cool it to room temperature, and the obtained product is designated as B-ZnO.

[0065] (3) Weigh 11.25g of B-ZnO and 0.84g of NaH respectively 2 PO 4 Disperse them evenly in 500mL of 0.6mL / mL ethanol aqueous solution, stir magnetically and boil and reflux for 7h. Drying at lower temperature for 4h to obtain P-ZnO;

[0066] (4) Weigh 0.26 g of P-ZnO and ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com