Uvioresistant coating for fabrics

An anti-ultraviolet and coating technology, applied in textiles and papermaking, etc., can solve problems such as skin erythema or sunburn, ozone layer destruction, pigmentation, etc., and achieve the effect of protecting the skin, good refraction and absorption capacity, and avoiding penetration of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

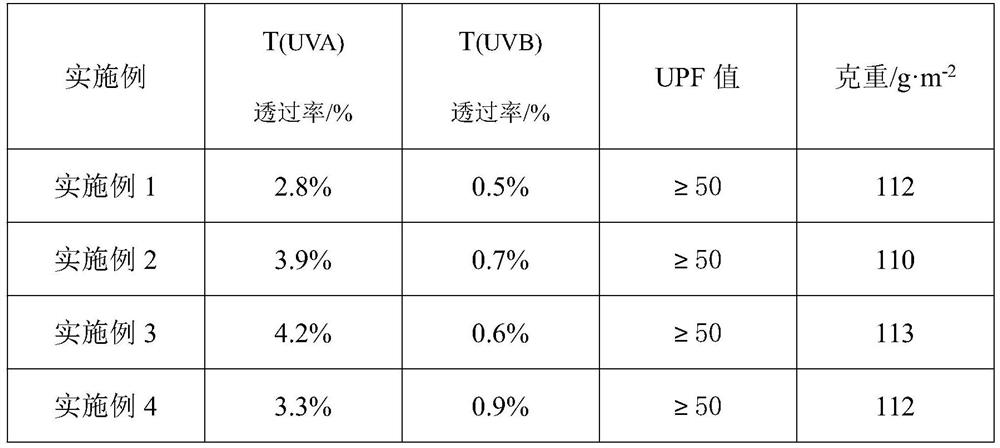

Examples

Embodiment 1

[0022] A kind of anti-ultraviolet coating for fabric, its preparation method is:

[0023] (1) Place 4 parts of the first component of titanium dioxide in an agate mortar and grind slowly, gradually add 6 parts of zinc oxide during the grinding process, continue grinding and dispersing for 10-20 minutes after the addition, and obtain the mixed filler A for later use;

[0024] (2) Take 2.5 parts of dispersant, 3 parts of membrane aid and 12 parts of the second component of titanium dioxide in an organic solvent, and stir at high speed for 10 minutes to mix completely;

[0025] (3) Dissolve 60 parts of epoxy resin in the product of step (2), continue stirring at high speed for 30 minutes, add 12 parts of Tinuvin477, mixed filler A obtained in step (1) and 0.8 parts of defoamer in turn during the stirring process, and stop stirring Afterwards vacuum degassing;

[0026] (4) Add 1 part of thickener to the product of step (3), and stir slowly for 20-60 minutes to obtain an anti-ultr...

Embodiment 2

[0028] A kind of anti-ultraviolet coating for fabric, its preparation method is:

[0029] (1) Place 5 parts of the first component of titanium dioxide in an agate mortar and grind slowly, gradually add 8 parts of zinc oxide during the grinding process, continue grinding and dispersing for 10-20 minutes after the addition, and obtain the mixed filler A for later use;

[0030] (2) Take 3 parts of dispersant, 3.5 parts of membrane aid and 10 parts of the second component of titanium dioxide in an organic solvent, stir at high speed for 10 minutes to mix completely;

[0031] (3) Dissolve 65 parts of epoxy resin in the product of step (2), continue to stir at high speed for 30 minutes, add 13 parts of Tinuvin477, mixed filler A obtained in step (1) and 1 part of defoamer in sequence during the stirring process, and stop stirring Afterwards vacuum degassing;

[0032] (4) Add 1.5 parts of thickener to the product of step (3), and stir slowly for 20-60 minutes to obtain an anti-ultra...

Embodiment 3

[0034] A kind of anti-ultraviolet coating for fabric, its preparation method is:

[0035] (1) Place 6 parts of the first component of titanium dioxide in an agate mortar and grind slowly, gradually add 6 parts of zinc oxide during the grinding process, continue grinding and dispersing for 10-20 minutes after the addition, and obtain the mixed filler A for use;

[0036] (2) Take 1.5 parts of dispersant, 2.5 parts of membrane aid and 9 parts of the second component of titanium dioxide in an organic solvent, and stir at high speed for 10 minutes to mix completely;

[0037] (3) Take epoxy resin and dissolve it in the product of step (2), continue to stir at high speed for 30 minutes, add 12 parts of Tinuvin477, mixed filler A and 0.5 part of defoamer obtained in step (1) successively during the stirring process, stop stirring and pump Vacuum defoaming;

[0038] (4) Add 1 part of thickener to the product of step (3), and stir slowly for 20-60 minutes to obtain an anti-ultraviolet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com