Scratch-resistant high viscosity flexible photovoltaic reflective film and preparation method thereof

A scratch-resistant, reflective sticker technology, used in optics, optical components, reflective reflectors, etc., can solve the problems of low adhesion between adhesives and welding tapes, inability to make full use of sunlight, and rising production costs for reflective films. Achieve excellent scratch resistance, good reflectivity and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

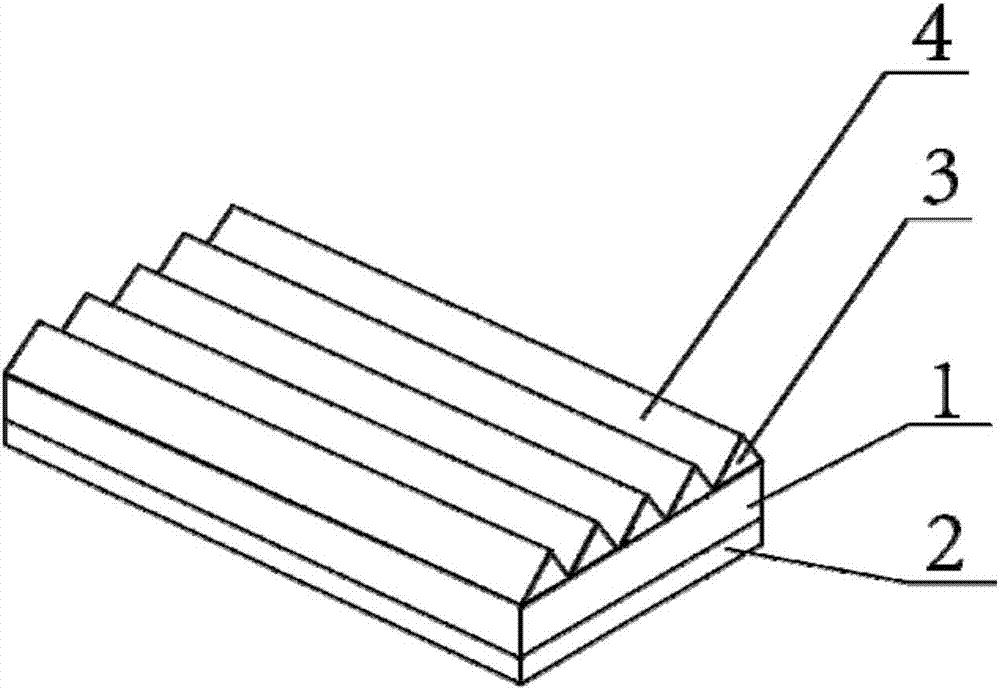

[0035] above as figure 1 The preparation method of the scratch-resistant high-viscosity flexible photovoltaic reflective film includes the following steps:

[0036]Step 1. Prepare the prism structure on the surface of the pressure roller through high-precision engraving equipment, and apply UV glue on the surface of the substrate layer 1 (metal sheets and inorganic particles can be added to the UV glue), and pass through the rubber roller at the same time UV curing is carried out to obtain a prism layer 3 with excellent strength;

[0037] Step 2. Metal and inorganic materials are plated on the surface of the prism by vacuum evaporation, magnetron sputtering or electroplating. The metal and inorganic materials are selected from aluminum, nickel, silicon dioxide and hafnium oxide, and the content of the latter three is controlled at 1 Within %, the surface of the prism is coated to form a coating 4;

[0038] Step 3. Pre-blend and granulate EVA, SIS and EAA resins, and then coa...

Embodiment 1

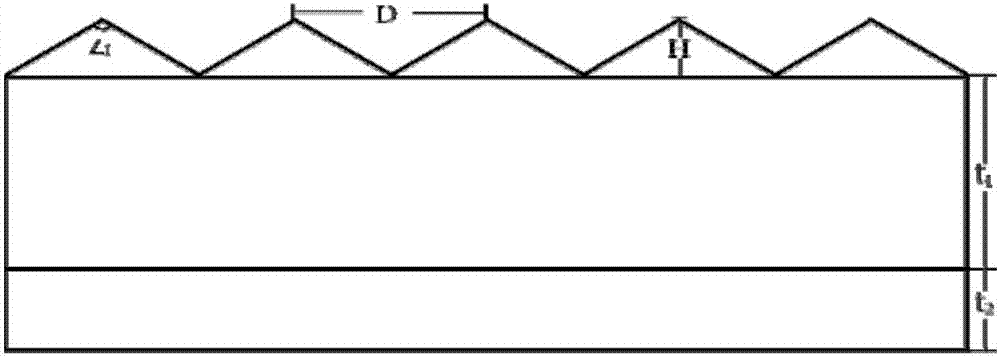

[0044] Such as figure 1 , figure 2 As shown, the scratch-resistant high-viscosity flexible photovoltaic reflective film has a four-layer structure, from top to bottom are coating layer 4, prism layer 3, substrate layer 1, hot-melt adhesive layer 2, substrate layer 1 thickness t 1 75μm, hot melt adhesive layer 2 thickness t 2 is 25 μm, and the thickness of the coating layer 4 is 50 nm. The ridge line of the prism forms an included angle of 0° with the direction of the ribbon, the distance between the ridge lines D is 50 μm, and the top angle of the prism ∠ 1 is 120°, and the section is an isosceles triangle.

[0045] The production method of the scratch-resistant high-viscosity flexible photovoltaic reflective film is as follows: firstly, the prism structure is pre-prepared on the surface of the pressure roller, the surface of the base film is coated with UV resin and passed through the pressure roller, and UV curing is carried out at the same time, and the micro-prism stru...

Embodiment 2

[0048] Such as figure 1 , figure 2 As shown, the scratch-resistant high-viscosity flexible photovoltaic reflective film has a four-layer structure, from top to bottom are coating layer 4, prism layer 3, substrate layer 1, hot-melt adhesive layer 2, substrate layer 1 thickness t 1 80μm, hot melt adhesive layer 2 thickness t 2 is 30 μm, and the thickness of the coating layer 4 is 70 nm. The ridge line of the prism forms an included angle of 0° with the direction of the ribbon, the distance between the ridge lines D is 30 μm, and the top angle of the prism ∠ 1 is 120°, and the section is an isosceles triangle.

[0049] The production method of the scratch-resistant high-viscosity flexible photovoltaic reflective film is as follows: firstly, the prism structure is pre-prepared on the surface of the pressure roller, the surface of the base film is coated with UV resin and passed through the pressure roller, and UV curing is carried out at the same time, and the micro-prism stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com