Carbonized bacterial cellulose-cadmium sulfide composite photocatalytic material as well as preparation method and application thereof

A technology of bacterial cellulose and composite photocatalysis, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems that are still in its infancy and require further research. Achieve high photocatalytic hydrogen production performance, simple operation, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

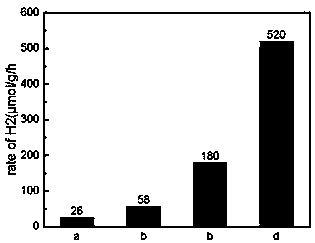

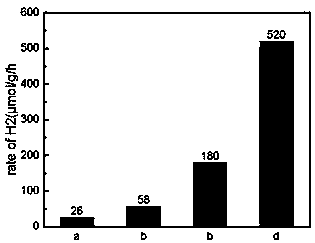

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with examples.

[0019] The main components and concentrations in medium A are: 25.0 g / L, tryptone 5.0 g / L, yeast extract 5.0 g / L, citric acid 1 g / L, Na 2 HPO 4 2 g / L, K 2 HPO 4 1 g / L, pH=5.0.

[0020] 1): Obtaining bacterial cellulose airgel: Gluconacetobacter xylinum preserved in a freeze-drying tube Gluconacetobacter xylinus ATCC 700178 Activated in basal medium A, to be Gluconacetobacter xylinus After dynamic culture for 96 hours, the obtained product was collected, washed successively with distilled water and 0.5M hydroxide solution, and then washed with distilled water until neutral, and finally the bacterial cellulose airgel was collected after vacuum freeze-drying.

[0021] 2): Preparation of bacterial cellulose-cadmium sulfide composite material: 0.1 g bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com