induction heating cooker

A technology for induction heating and cooking appliances, which is applied to induction heating, induction heating devices, electric heating fuels, etc., can solve the problems of uneven temperature of food materials, uneven temperature of food materials, etc., and achieve the effect of suppressing uneven temperature and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0029] (the whole frame)

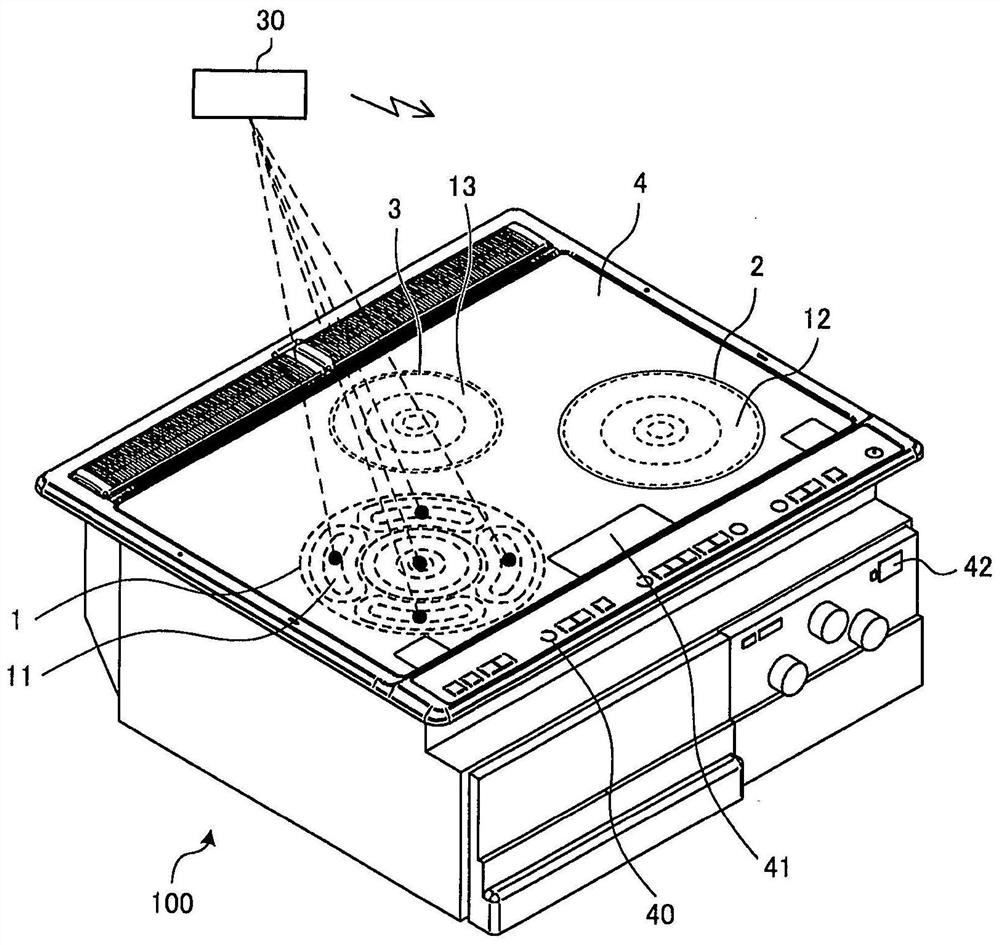

[0030] figure 1 It is a perspective view which shows the whole structure of the induction heating cooker of Embodiment 1.

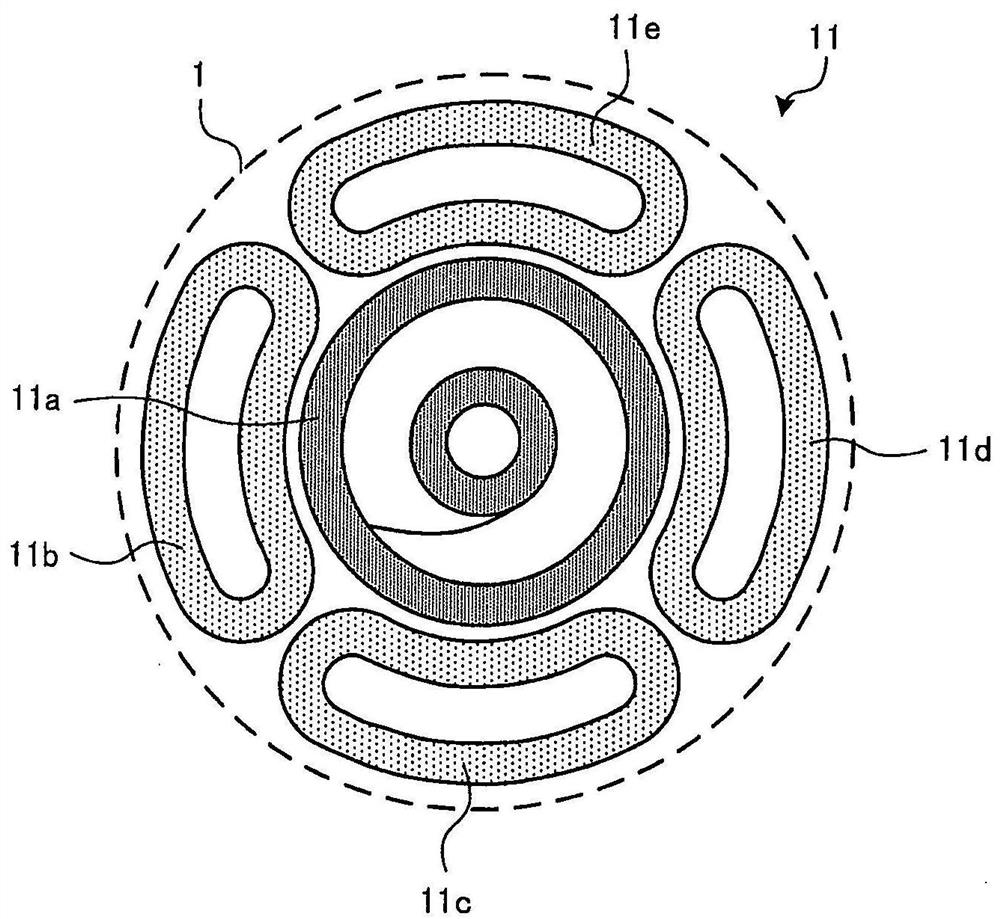

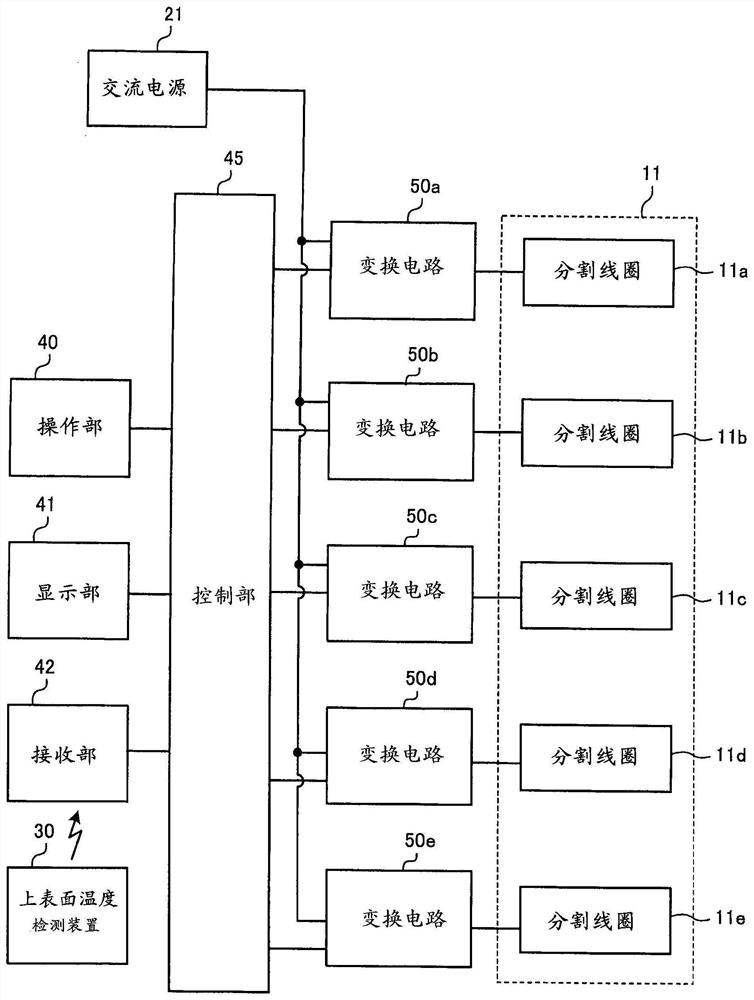

[0031] like figure 1 As shown, the upper part of the induction heating cooker 100 has a top plate 4 on which objects to be heated such as pots and pans into which ingredients are placed are placed. The top plate 4 is provided with a first heating port 1, a second heating port 2, and a third heating port 3 as heating ports for inductively heating the object to be heated, and a first heating member 11, a The second heating member 12 and the third heating member 13 can place an object to be heated with respect to each heating port and perform induction heating.

[0032] On the top plate 4, the rough mounting positions of the pans are formed corresponding to the heating ranges (heating openings) of the first heating member 11, the second heating member 12, and the third heating member 13 by applying paint, printing, etc. The cir...

Embodiment approach 2

[0107] In this Embodiment 2, the structure and operation|movement which detect the temperature difference of the thickness direction (vertical direction) of a food material are demonstrated.

[0108] Hereinafter, the structure and operation|movement of the induction heating cooker 100 in this Embodiment 2 will be demonstrated centering on the difference from Embodiment 1 mentioned above.

[0109] (structure)

[0110] Figure 8 It is a plan view showing the first heating member and the bottom surface temperature detection device of the induction heating cooker according to Embodiment 2.

[0111] Figure 9 It is a side cross-sectional view schematically showing the positions of temperature detection by the upper surface temperature detection device and the bottom surface temperature detection device of the induction heating cooker according to Embodiment 2. In addition, in Figure 9 In , some structures are omitted from illustration. in addition, Figure 9 A longitudinal s...

Embodiment approach 3

[0146] In the present third embodiment, an operation for detecting empty firing in which the heating operation is continued in a state in which no food material has been put into the object 5 to be heated will be described.

[0147] Hereinafter, the operation|movement of the induction heating cooker 100 in this Embodiment 3 is demonstrated centering on the difference from the said Embodiment 1 and 2. FIG.

[0148] Figure 11 It is a flowchart showing the heating operation of the induction heating cooker of Embodiment 3. Below, based on Figure 11 Each step is explained.

[0149] In addition, as an application of the induction heating cooker 100, there is a "preheating mode" for heating the temperature of the object 5 to be heated to a set temperature. Hereinafter, cooking modes other than the "preheating mode" are referred to as "normal mode".

[0150] (Empty burn detection action)

[0151] When the user turns on the induction heating cooker 100 and starts the heating ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com