Fixing device and image forming device

一种图像、加热辊的技术,应用在感应加热装置、应用电荷图形的电记录工艺、应用电荷图形的电记录工艺的设备等方向,能够解决不能够高精度地控制加热区域温度、检测灵敏度迟钝、加热辊冒烟等问题,达到良好快速复印性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0071] [A] Image forming device

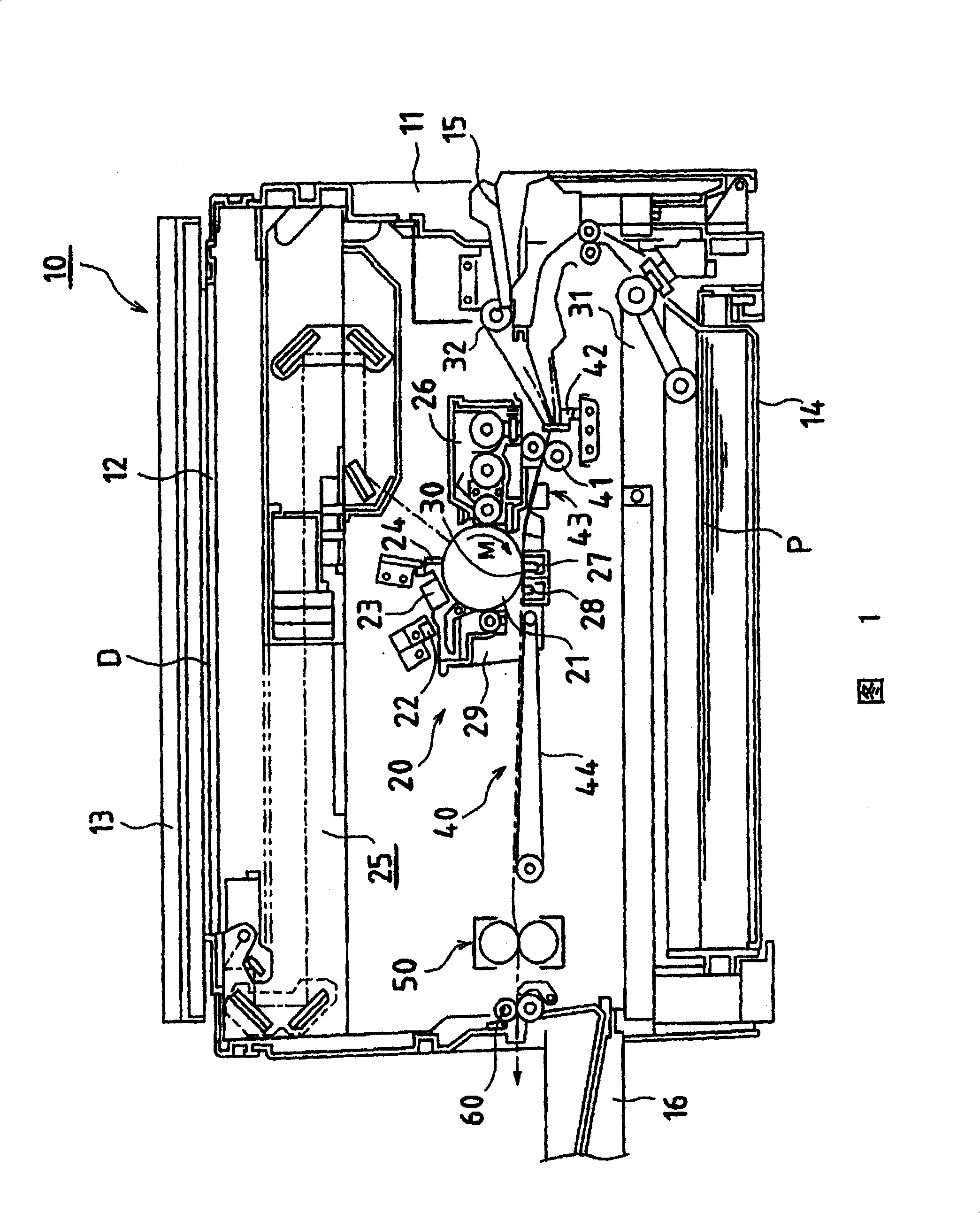

[0072] FIG. 1 is a cross-sectional view showing an example of an image forming apparatus of the present invention.

[0073] The image forming apparatus 10 shown in FIG. 1 is equipped with a housing-shaped apparatus main body 11, and an image forming apparatus for forming an image through image forming processes such as charging, exposure, development, transfer, and cleaning is disposed inside the apparatus main body 11. Section 20. Further, on the upper surface of the apparatus main body 11 , a platen glass 12 serving as a platen glass 12 and a platen cover 13 for pressing the document D placed on the platen glass 12 are provided.

[0074]A control panel (not shown) as an input / display unit is disposed on the front edge portion of the upper surface of the device main body 11 . Attached to the bottom of the apparatus main body 11 is a paper fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com